I-Graphite, uhlobo olubonakala lulula lwekhabhoni, lunesici esingejwayelekile: iphuzu eliphakeme kakhulu eliphakeme kakhulu. Le ndatshana idlulela ezweni elihehayo le-graphite, ihlola iphuzu layo elihlukile lokuncibilika - ifinyelela cishe ku-4000 ° C - kanye nezakhiwo eziphawuleka ezenza amabhlokhi we-graphite asemqoka ezihlokweni zezimboni eziphakeme. Ukuqonda lezi zinzuzo kuzokhanyisa ukuthi kungani i-graphite iyisitatimende esibucayi sezimboni ezisukela ekukhiqizweni kwensimbi kuya ku-metlulgy ethuthukile.

Yini i-graphite futhi yini eyenza iphuzu laso elincibilikayo liphezulu kangaka?

I-Graphite iyindlela eyenzeka ngokwemvelo yekhabhoni, lapho yilowo nalowoI-Carbon AtomISBomvu kwabanye abathathuesakhiweni se-hexagonal lattice, kwakha amashidi amafulethi. Lawa mashidi asehlanganiswe ndawonye, aphethwe nguamabutho abuthakathaka we-van der Waals. Lesi sakhiwo esiyingqayizivele siyisihluthulelo seIzakhiwo zegrafu, kufaka phakathi umxhweleiphuzu eliphakeme elibi. Ngokungafani nezinto zokwakha ezinamabhondi aqinile kuzo zonke izinkomba, okuqinileAmabhondi angejwayelekileNgaphakathi kwamashidi we-graphite adinga amandla amakhulu ukuphula. Kulinganiselwaiphuzu lokuncibilika kwe-graphiteezungeza cishe ama-degree angama-4000icelsius(cishe ama-degree angama-7230fahrenheit), uTestamente kumandla walezi zibopho.

Kuyathakazelisa ukuthi i-graphite ayithi "incibilike" ngokweqiniso ngomqondo wendabuko. Esikhundleni salokho, ithola ukuguquguquka, iguqulwa ngokuqondile kusuka ku-solid to gesi ngokweqileUkushisa okuphezulu. Leli phuzu eliphansi livame ukubhekiswa kuloiphuzu elincibilikayo le-graphite. -QisaI-Carbon Atomukuhlelwa namandla weAmabhondi angenasisekelo anamanye amakhabhoniama-athomu yilokho okuvumela i-graphite ibemelana na-okukhulu okunjaloukushisa okuphezulu.

Kungani iphuzu eliphakeme kakhulu le-graphite (~ 4000 ° C) inzuzo enkulu?

Iphuzu eliphakeme lika-graphiteakuyona nje iqiniso elithandekayo lesayensi; Kungumguquki womdlalo wezinqubo eziningi zezimboni. Lesi sici senza ukuthi i-graphite ibe yinto ebaluleke kakhulu ezindaweni lapho ezinye izinto zingavele zikhanye. Cabanga ngamamitha ensimbi, lapho i-molten Metal ifinyelela amazinga okushisa angaphezu kuka-1500 ° C. Noma cabanga izinqubo zensimbi ecindezela kakhulu. Amandla wegrafu ukuze alondoloze ubuqotho bayo bokuhleleka ekushiseni okwedlulele kwenza kube fanele ukuhlakaniphaI-graphite ecashiles ngezinsimbi ezincibilikayo,I-electrodes for i-arc furc arc, kanye nama-linings forUkushisa okushisa okushisas.

Le khasiiphuzu eliphakeme elincibilikayo lenzagraphite isakhi esithembekile ezimweni lapho kugcinwa khona ukuqina kobukhulu ngaphansiUkushisa okuphezulukubaluleke kakhulu. Lokhu kuthembeka kuhumushela ngqo ekusindisweni kwezindleko kanye nokuphepha okwandayo ekufuneni izilungiselelo zezimboni. Isibonelo, ukusebenzisa izakhi ze-graphite kunciphisa ubungozi bokwehluleka kwemishini ngenxa yokushisa ngokweqile, ukuqinisekisa ukusebenza okuqhubekayo nokuvimbela isikhathi sokuphumula.

Kwenzekani lapho uzama ukuthola iphuzu elinembile lokuncibilikisa iphuzu?

Ngenkathi sivame ukucosha ama-4000 ° C njengeiphuzu lokuncibilika kwe-graphite, Ukukhomba izinga lokushisa eliqondile kuwumsebenzi oyinkimbinkimbi wesayensi. Njengoba kushiwo ngaphambili, ama-sublimes we-graphite kunokuba ancibilike emqondweni ojwayelekile. Izinga lokushisa lapho lokhu kwenzeka khona hhayi iphuzu elinqunyelwe kepha kunalokho kuncike ezintweni ezifana nengcindezi kanye nobumsulwa be-graphite. Ngaphansi kwengcindezi ejwayelekile yezulu, i-graphite izokwengeza cishe ngo-3652 °icelsius. Kodwa-ke, ngaphansi kwengcindezi ephezulu kakhulu, eduze kwethiyori yayoiphuzu elincibilikayo, leli lokushisa lingasondela ku-4000 ° C.

Ngaphezu kwalokho, ukuba khona kokungcola ngaphakathi kwesakhiwo se-graphite nakho kungathonya ukusebenza kwayo okushisayo. Ngakho-ke, lapho uxoxaiphuzu elincibilikayo le-graphite, kuvame ukunemba ngokwengeziwe ukubhekisa ebangeni kunokuba kube yinani elithile elinobuhlakani. Le nnounce ibalulekile onjiniyela kanye nososayensi bezinto ezibonakalayo abasebenza ngegrafu kuzinhlelo zokusebenza ezikhethekile.

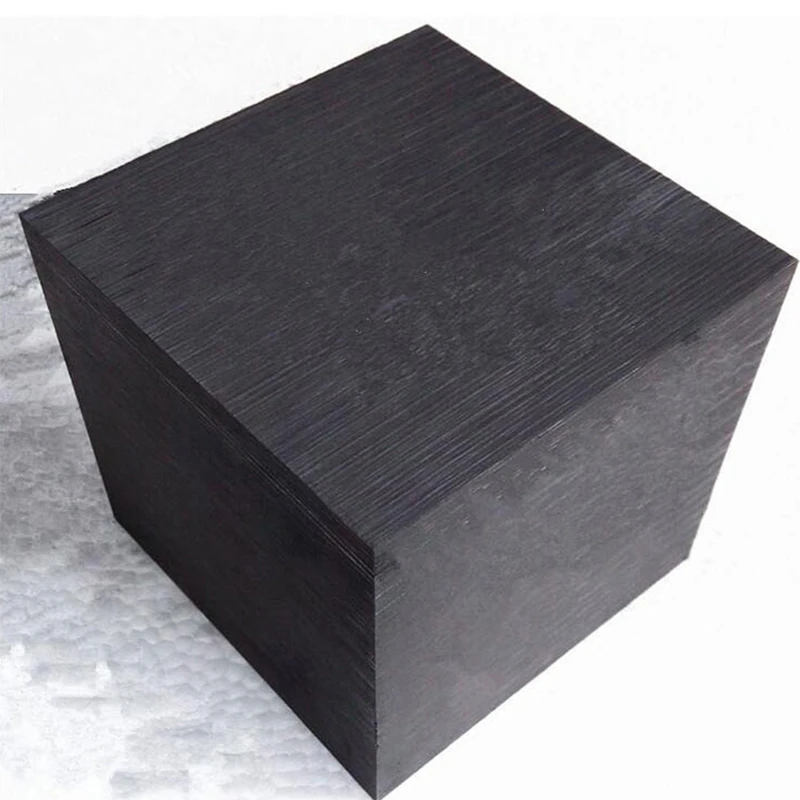

Uma ucabangela izinhlelo zokusebenza zokushisa eziphakeme, yini amabhlogo we-graphite asetshenziselwa?

Amabhulokhi we-Graphite asetshenziswa ikakhulukazingohlolo olukhulu lweUkushisa okuphezuluizinhlelo zokusebenza, zifaka amandla abo ahlukileiphuzu eliphakeme elibinokunye okunenzuzoIzakhiwo zegrafu. Embonini yensimbi,Amabhulokhi we-Graphite asetshenzisiwenga-I-electrodes emagumbini agesi kagesi abalulekile ukuze ancibilike insimbi ye-scrap. LeziI-electrodeisidingo sokuthimelana na--khulu namandlaizinga lokushisa eliphakeme le-arcngaphandle kokonakalisa.

Ngaphandle kwensimbi,I-graphite ecashileama-S aqashwe kabanzi ngokuncibilika kwezinsimbi ezahlukahlukene kwabatholile futhiI-Metallurgical Feraces. Ukumelana kwabo noUkumelana Kwecala Okushisayofuthi i-chemical inecness ibenza babe yinto efanelekile yokuba nezinto ezincibilikisiwe.Amabhulokhi we-Graphite nawo asetshenziswaukudalaizinsimbi nezinto zokwakhaphakathi kwa-Ukumelana Nefafuthi ngisho nasemishini ekhethekile efanaIsithando somlilo esisodwaisetshenziswa e-semiconductor ekhiqizweni. -AboUkumelana nokushisa okuphezuluumane nje ungenakuphikwa ezinye izinto eziningi. Thina, njengeIfektri enemigqa engu-7 yokukhiqiza, khiqizaIzinto ze-graphite ezisezingeni eliphakemeokuhlangabezana nalezi zidingo ezifunwayo.

Nakhu umbono osheshayo wokuthi ungathola kuphi amabhlogo wethu we-graphite asebenza:

- Izimbatho zensimbi:Nga-Electric Arc Uthando lwe-Electrodes.

- Okutholakele:Phakathi kwa-I-graphite ecashiles ukuncibilika izinsimbi ezahlukahlukene.

- Izinkampani zeMetallurgy:Nga-izinsimbi nezinto zokwakhaphakathi kwa-I-Metallurgical Feraces.

- Imboni ye-Electronics:Phakathi kwa-Isithando somlilo esisodwafuthi njengobaI-Anode ye-Electron Tube Anodes.

- Imboni yamakhemikhali:IngomaneAbashisi bokushisa embonini yamakhemikhalingenxa yaboUkumelana nokugqwala.

Ngaphandle kokumelana nokushisa nje: Yiziphi ezinye izakhiwo ezibalulekile zamabhulokhi we-graphite okufanele ngizazi?

Ngenkathi kuphawulekaiphuzu eliphakeme elibiukudweba okuyisisekelo,I-Graphite inezimpawu eziningi ezinhle kakhuluLokho kwenza kube yinto eguquguqukayo. OkuhlukileUkuvuselelwa okushisayoivumela ukudluliselwa kokushisa okusebenzayo, okubalulekile kuzinhlelo zokusebenza ezinjeAbashisi bokushisa embonini yamakhemikhali. Ngaphezu kwalokho, imiboniso ye-graphite enhle kakhuluukuqina kukagesi, okwenza kube kuhleI-electrodes. Ibuye ibe ne-lowukunwebeka okwenziwe nge-thermal, okusho ukuthi akukukhuli okuningi lapho kufuthelwa, okubalulekile ukuze kugcinwe ukuqina kobukhulu ngaphakathiokushisa okuphezuluizindawo.

Enye inzuzo ebalulekile ukulandisa okungokwemvelo kwe-graphite. Izibopho ezibuthakathaka phakathi kwezendlalelo zibavumela ukuba zishayele zidlule kalula, okwenza i-graphite ibe lusizo owomile. Ngaphezu kwalokho, imiboniso ye-graphite enhle kakhuluUkumelana nokugqwala, ikakhulukazi kuma-acid futhialkali, kuphinde kwandise isikhathi sayo sokuphila ezilungiselelweni ezinzima zezimboni. Le nhlanganisela yeimpamba, ugesi, omakhemikhali, namakhemikhaliIzakhiwo zegrafuKwenza kube yinto ebalulekile emikhakheni eminingi.

Ngabe i-graphite's ephezulu izuzisa kanjani amazinga okushisa aphezulu okushisa?

Le khasiUkusebenza okuphezulu okushisayoi-graphite idlala indima ebalulekile ekusebenzeni kahle nasekusebenzeniUkushisa okushisa okushisas. Le mpahla ivumela ukushisa kusatshalaliswa ngokulinganayo kulo lonkeimbuthuma, ukunciphisa amabala ashisayo kanye nokuqinisekisa ukufudumala okufanayo kwezinto zokwakha ezicutshungulwayo. Kuzinhlelo zokusebenza ezinjeI-Silicon Carbide Fourse, lapho ukulawulwa kokushisa okunembile kubalulekile, amandla we-graphite wokushisa ukushisa ngokushesha inzuzo enkulu.

Ukusebenzisaamabhlogo we-graphite asetshenziselwa ukuthwala okuphezulu kwesithakoUkwakha noma njengoba izakhi zangaphakathi ziholela emijikelezweni yokushisa ngokushesha kanye nokuncishiswa kwamandla. Lokhu kuhumushela izindleko eziphansi zokusebenza kanye nokukhiqizwa okukhulayo kwezimboni ezincike kukhoukushisa okuphezuluizinqubo. Ukudluliselwa okushisa okusebenzayo nakho kunomthelela ekuvuleni isikhathi eside kwesithando ngokwako ngokunciphisaimpambaukucindezela kwezinye izingxenye.

Kuthiwani ngokumelana nokugqwala? Ingabe amabhlogo we-graphite angakwazi ukumelana nezimo zomthamo wesitabane?

Ukumelana nokugqwalakungenye imfanelo ebalulekile eyenza i-graphite ilungeleUkushisa okushisa okushisaizindawo. Ngokungafani nezinsimbi eziningi ezincipha lapho zivezwa amazinga okushisa aphezulu kanye nezinto ezisebenzayo, ama-graphite akhombisa ukungajabuli okumangazayo. Ingakwazimelana na-ukuvezwa kumakhemikhali amaningi awonakalisayo, kufaka phakathi ama-acid aqinile futhialkali, okwenza kulungele ukusetshenziswa ngaphakathiI-Metallurgical Feraceskanye nemishini yokusebenza kwamakhemikhali.

Lokhu kumelana nezeI-Alkali ne-Organic Solvent Cornisionkunwebeka kakhulu isikhathi sokuphila kweimishini ye-graphite, ukunciphisa isidingo sokufakwa kabusha kwezidingo futhi kunciphise isikhathi sokuphumula. Ngisho nasekubakhona kwama-molten izinsimbi kanye ne-slag, i-graphite ephezulu, efana neyethuukusebenza okuphezuluAmabhulokhi, agcina ubuqotho bayo, aqinisekise ukusebenza okuthembekile nokuhlala isikhathi eside. Leliukuqina okuhle kwamakhemikhaliinzuzo enkulu ngezinto ezihlukile.

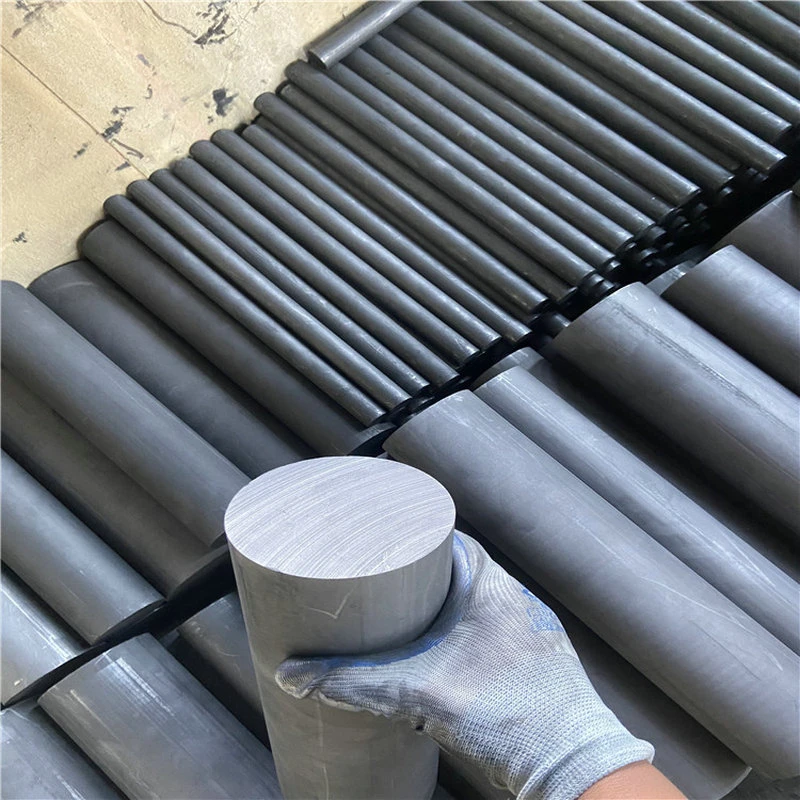

Ingabe kukhona amamaki ahlukene amabhlokhi we-graphite asetshenziselwa izidingo ezihlukile zokushisa eziphakeme?

Yebo, umhlaba we-graphite uhlukile, futhi izinhlelo ezihlukile zifuna okuthileIzici zegrafu. Ngakho-ke, amabanga ahlukahlukene weamabhlogo we-graphiteakhiqizwa ukuze ahlangabezane nalezi zidingo ezahlukahlukene. Okwezicelo ezifunwa kakhulu ezifanaI-Ultra HighubuqhwagaI-electrodes ku-Steelmaking,Ama-electrodes we-UHP graphitezisetshenziswa, zibonakala ngobumsulwa babo obuphezulu nobunzima. Ngezicelo ezingenamkhawulo, amanye amabanga afana namandla aphezulu (i-HP) noma ngisho namandla ejwayelekile (RP) Graphite akwanele.

Le khasiivolumu ye-graphiteFuthi ukuqina kwalo nakho kudlala indima ebalulekile. Ngokwesibonelo, kwethuI-0.8mm ephezulu ye-stensity graphityna-I-graphity ye-graphity ephezulu ye-bulkIminikelo yenzelwe izicelo ezidinga amandla aphezulu kanye nemishini. Le khasiumshiniAmandla wegrafu futhi ayisici, namanye amabanga okuba lula ukuwathola ezingxenyeni eziyinkimbinkimbi. Ukuqonda le nnoni kuvumela abasebenzisi ukuthi bakhethe okulungileI-Graphite Blockibanga ngokuqondileUkushisa okuphezuluIzidingo. NjengokuholaIfektri ye-electrode ye-professional graphite, siyanikelaAmabanga ahlukahlukeneukuhambisana nezinhlobonhlobo zezicelo.

Kungani kufanele i-Insimbi Mills kanye nama-FIEFIMes abheka amabhlokhi aphezulu we-graphite afana neyethu?

Ngamalunga wensimbi nabatholakele, batshala imali ngaphakathiamabhlokhi aphezulu we-graphiteyisinqumo samasu esithinta ngokuqondile ukusebenza kahle nokusebenza. -KwethuIzinto ze-graphite ezisezingeni eliphakemehlinzeka kakhuluukuqina kukagesi, okuholela ezinqubweni ezisebenza kahle zokuncibilika emaflethini kagesi we-arc. OkuhlukileUkuvuselelwa okushisayoIqinisekisa ngisho nokusatshalaliswa kokushisa, ukunciphisa ukusetshenziswa kwamandla kanye nokwenza ngcono ikhwalithi yensimbi encibilikisiwe.

Ngaphezu kwalokho, ophakemeUkumelana nokugqwalana-Ukumelana Kwecala OkushisayoAmabhulokhi ethu we-graphite ahumushela ku-Lifespan ende, ukunciphisa izindleko zokubuyiselwa kanye nesikhathi sokuphumula. -KwethungokuluciAmabhulokhi aqinisekisa ukusebenza okuqondile nokuthembekile. Siyakuqonda ukukhathazeka okubucayi kwamakhasimende ethu angaba khona njengoMark Thompson, ikakhulukazi mayelanaUkuhlolwa kwekhwalithikanye nesidingo sezinto ezihambisana nazoamazinga aphesheya. Ukuzibophezela kwethu ekuhlolweni kwekhwalithi nokuqina kuqinisekisa ukuthi amabhlokhi ethu we-graphite aletha ukusebenza okungaguquki nokuthembekile.

Ngingazitholaphi amabhlokhi athembekile futhi aphezulu we-graphite e-high high freethac furemece body?

Ukuthola umphakeli othembekile weAmabhulokhi we-graphite aphezulu aphezulukubalulekile ukuthi izimboni zisebenzaUkushisa okushisa okushisas. NjengokuhlonishwaIfektri enemigqa engu-7 yokukhiqizakusekelwe kuIzitsha zokudlela zebumba uqobo, thina, [igama lenkampani yakho - Allen], uchwepheshe ekukhiqizeniAma-electrodes we-graphite nemikhiqizo ye-graphiteokuhlangabezana nezidingo eziqinile zezimboni ku-I-USA, eNyakatho Melika, eYurophu, e-Australia, nangale kwalokho. Siyaqonda izidingo zeamamitha ensimbi, Ama-operacer kagesi we-arc isithando, OKUFANELEKILE, futhiIzinkampani zeMetallurgy.

Ukuzibophezela kwethu ekusebenziseniIzinto ze-graphite ezisezingeni eliphakeme, kuhlanganiswe nezinqubo zethu zokukhiqiza ezithuthukile, kuqinisekisa ukuthi amabhlokhi ethu we-graphite aletha ukusebenza okuhlukile nokuphila isikhathi eside. Sinikeza uhla lwamabanga, kufaka phakathiAma-electrodes we-UHP graphite, ukunakekela izidingo zohlelo lokusebenza ezahlukahlukene. Ungahlola ububanzi bethu beUkusebenza okuphezulu kwe-anode anode carbon block, I-graphite yamandla aphezulu, futhiInduku ye-graphiti evutha ama-electrodesUkuthola ikhambi elifanele ngezidingo zakho. Ngezinhlelo ezithile ezinjengezinjini zokuphuma kukagesi, futhi siyanikelaI-EDM Graphite. Sikumema ukubaVuselela ukukhetha kwakhoFuthi usicabangele njengoMlingani wakho othembekile kuzo zonke izidingo zakho ze-graphite.

Ukuthathwa Key:

- I-Graphite iqhosha ngokuhlukileiphuzu eliphakeme elibiCishe ngo-4000 ° C, okwenza kube kuhle ngezicelo zokushisa ngokweqile.

- Leli phuzu eliphakeme eliphakeme kungenxa ye-strongAmabhondi angejwayelekilengaphakathiI-Carbon Atoms ngesakhiwo sayo esiyingqayizivele esihlukile.

- Kusetshenziswa amabhlokhi we-graphitekakhulu ngaphakathiUkushisa okushisa okushisas,I-graphite ecashiles, futhi njengobaI-electrodes e-sentmaking.

- Ngaphandle kokumelana nokushisa, i-graphite inikeza okuhle kakhuluUkuvuselelwa okushisayo, ukuqina kukagesi, futhiUkumelana nokugqwala.

- Amamaki ahlukene we-graphite akhona, njengeAma-electrodes we-UHP graphite, ehambisana nezidingo ezithile zokusebenza.

- Enqumaamabhlokhi aphezulu we-graphiteIqinisekisa ukusebenza kahle, isikhathi eside, kanye nokusebenza kwezindleko zemisebenzi yezimboni.

- Cabanga ukuhlola uhla lwethuAmandla we-graphite ajwayelekile we-graphitengezicelo ezimbalwa eziqinile.

Jike

Isikhathi sePosi: 02-05-2025