Ama-anode wekhabhoni angamaqhawe angasebenzialuminiyamuimboni. BayabucayiingxenyeEmandleni-igxililei-electrolysisinqubo eguqukayoumsindonakuguquguqukayoinsimbi yanama iniSisebenzisa yonke indawo. Ukuqonda ukukhiqizwa kwabo, ukusebenza, kanye nekhwalithi kubaluleke kakhulu kunoma ngubani obandakanyeke kuwoukukhiqizwa kwe-aluminium, ikakhulukazi abaqeqeshiwe bokuthengwa kwempahla njengoMark Thompson abazulazula ezinkingeni zokuthola lezi zinto ezibalulekile. Le ndatshana idlulela emhlabeni weI-Carbon Anode, ehlola izindima ezibalulekile zeUPetroleum Cokekanye nama-Binders, izinkampani zeukukhiqizwa kwe-anode, indlela yabo yokuziphatha ngesikhathiI-Aluminium Electrolysis, kanye nokucatshangelwa okusemqoka kokuqinisekisa ukubanzinza,ikhwalithi ephezuluukuhlinzekwa. Ukufunda lokhu kuzohlinzeka ngokuqonda okubalulekile ekusebenzeni kahleUkubhema i-AlumininumUkusebenza kanye nokwenza izinqumo zokuthenga ezinolwazi.

Kuyini ngempela i-carbon anode futhi kungani kubalulekile ukukhiqizwa kwe-aluminium?

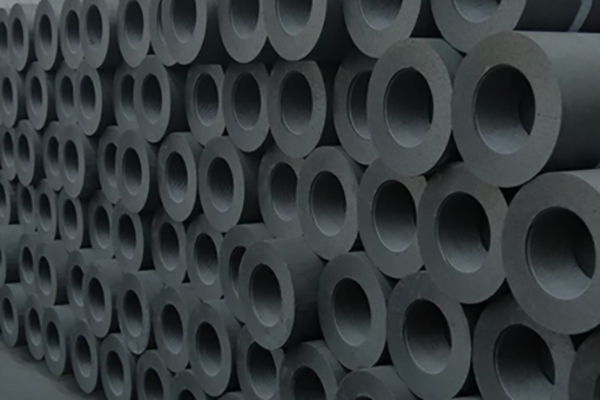

A I-Carbon Anodeempeleni i-block enkulu eyenziwe ngokuyinhloko kusuka kuzinto ezisetshenzisiwe ze-carbonaceous, ikakhulukaziCalcated Petroleum CokeBopha kanyekanyeI-Coal Tar Pitch. Ngokwesimo sangempelaukukhiqizwa kwe-aluminium, indima yayo iyisisekelo ngokuphelele. Isebenza njengengxenye eyodwa yeI-Electrochemicaliseli (ikakhulukazi, i-electrode enhle nomai-anode ne-cathodepair) esetshenziswe kwinqubo yehholo-héroult, evelele-kwezimboniindlela yokukhiqizaaluminiyamuEmhlabeni jikelele. Ngaphandle kwalezi anode, thei-electrolysisokudingekayo-mbethelwe umsindona(I-Aluminium Oxide) ibe yinhleI-Aluminium Metalumane akwazi ukwenzeka kahle.

Umsebenzi oyinhloko weI-Carbon AnodengesikhathiI-Aluminium Electrolysisibili. Okokuqala, kuqhuba okudingekayoElectric yamanjekuI-electrolyticUkugeza (molton cryoliteequkethe ukuncibilikaumsindona). Okwesibili, futhi ngokuhlolisisa, kubamba iqhaza ngqo kuokuthakiweyoukuphendula. Le khasiumoya ohlanzekileama-ion akhishwe kuumsindonangesikhathii-electrolysisbaphendule ngekhabhoni ye-anode atUkushisa okuphezulu, kwakhaI-Carbon Dioxide neCarbon Moxideamagesi. Lokhu kuphendula yingakhoKudliwa ama-anode e-carbonNgesikhathiInqubo yokukhiqiza. Leliukudliwakusho ukuthi ama-anode adinga ngezikhathi ezithileukubeka endaweni, ubenza babe yizindleko ezibalulekile zokusebenza kanye nokusebenza okubalulekile ngaphakathiUkubhema i-Alumininum. Ukusebenza kwabo kuthinta ngokuqondile ukusebenza kahle kwamandla,insimbi yanama iniubumsulwa, kanye nezindleko zokukhiqiza jikelele.

Kwenziwa kanjani inqubo yokukhiqiza i-carbon anode?

Le khasiukukhiqizwa kwe-carbon anodeiyinqubo eyinkimbinkimbi, yenqubo ehlukahlukene eyenzelwe ukudala ama-anode anomzimba athile futhiokuthakiweyoizakhiwo. Kuqala ngokukhethwa ngokucophelela nokulungiselelaAma-Raw material, ngokuyinhlokoUPetroleum Cokena-ibha yamalahlepitch. Le khasiUPetroleum Coke, okusebenza njenge-aggregate, kuqala ukubalwa (kufuthelwe phezuluizinga lokushisa nokubandaUma kungekho komoya) ukususa into eguquguqukayo futhi wandiseincekusanana-ukuqina kukagesi. LeliCalcated Petroleum Cokeichotshozwa futhi yahlolelwa izingxenyana ezithile zesayizi - leziIzinhlayiya ze-Coke.

Lezi zihlukanisweIzinhlayiya ze-Cokezixubene noketsheziI-Coal Tar Pitch, okusebenza njenge-isibopho, ephethecockendawonye. Lokhu kuxuba kwenziwa lapho kuphakamaizinga lokushisa nokubandaUkuqinisekisa ukuthi i-pitch igeleza futhi icoshe izinhlayiya ngempumelelo. Ama-paste aphumayo asungulwa emabhulokini amakhulu, ngokuvamile ngokusebenzisana kwe-vibro noma ukucindezela. Lawa ama-anode "aluhlaza" asebuthaka. Isinyathelo esibalulekile ukubhaka, lapho ama-anome aluhlaza afudunyezwa khona kancane ezindlini ezinkulu ezinsukwini ezimbalwa ukuya kumazinga okushisa avame ukwedlula ngo-1100 ° C. Le nqubo yokubhaka i-COBONIZES I-Pitch Binder, idala okuqinile, okuqinileI-Carbon Anodevimba, bese ushayela noma yiziphi izinto zokwakha ezisele. Kwesinye isikhathi, okunyeinqubo yokwelashwathandaukusakaza(ukufudumeza amazinga okushisa aphakeme ngisho nangokwengeziwe, ~ 2500 ° C +) angaqashwa ngezinhlelo ezithile ezidinga izakhiwo ezithuthukisiwe, yize lokhu kuvame kakhulualuminiyamu -mbethelweukufaka anodes kuqhathaniswa, yithi,i-graphiteAma-electrodes ama-electrodes ensimbi.

Yiziphi izinto zokwenziwa ezibalulekile, ikakhulukazi i-petroleum coke, esetshenziswa ekukhiqizeni i-anode?

Ikhwalithi yokugcinaI-Carbon Anodeixhumeke ngokomqondo kwikhwalithi yezinto zayo zokufaka. Okuyisisekeloimpahla eluhlaza, okwenza ama-65-75% we-Anode's Mass,UPetroleum Coke. Lokhu kungukuphumelela kwenqubo yokucwengwa kwamafutha. Kodwa-ke, hhayi njeUPetroleum Cokengizokwenza njalo. Ingomaneukukhiqizwa kwe-anode, i-sulfur ephansi, okuqukethwe kwensimbi ephansi "anode-grade"cockeiyadingeka. Kufanele kube nokubaleka, aokushisa okuphezuluinqubo eguqula ukwakheka kwayo kakhulu, ukuthuthukaukuqina kukagesina-incekusana, okubucayiipharameterS ngempumeleloi-electrolysis. Ukuvumelana nobumsulwa beCalcated Petroleum Cokeukuhlinzeka kugxile kakhulu kubakhiqizi be-anode futhi, ngenxa yalokhoaluminiyamuabakhiqizi. Ukwehluka kungathinta kakhulu ukusebenza kwe-anode futhiukudliwaamanani.

Ukhiye wesibiliingxenyeyi-isibopho, ngokujwayelekileI-Coal Tar Pitch, kwakha cishe ngo-15-25% wokuhlanganiswa. Le pitch ithathwe kusuka ekuhlolweni kweibha yamalahle, ukuprouct ofamalahleukukhwehlela embonini yensimbi. I-pitch kumele ibe nezakhiwo ezithile, kufaka phakathi iphuzu elifanele lokuthambisa, ukubonakala, kanye nenani lokukhwehlela, ukubopha ngempumeleloIzinhlayiya ze-CokeNgesikhathi sokuxuba nokwakha, bese uveza i-matrix eqinile yekhabhoni ngemuva kokubhaka. Kwesinye isikhathi, ama-anode ane-anode asetshenzisiwe (izingxenye ezingasetshenziswanga zokuchitha ama-anode) nazo zichotshozwa futhi zingezwe emuva kuxube, ngcono ukusetshenziswa kwezinsiza. Ukugoqa okungaguquki, kwekhwalithi ephezuluI-High Carbon Coal tal asphalt(pitch) kanyeUPetroleum Cokengumsebenzi oqhubekayo wamafektri afana neyethu, uqinisekise owokugcinaI-Carbon Anodeihlangabezana nezidingo zokusebenza eziqinile.

Isayensi ichaze: Ngabe isebenza kanjani i-carbon anodes ku-aluminium elemetrolysis?

Inqubo yehholo-Héroult iyitshe legumbi lanamuhlaukukhiqizwa kwe-aluminium, noI-Carbon Anodeisesikhungweni sayo esisebenzayo. Inqubo yenzeka kumaseli amakhulu we-electrolytic noma "amabhodwe." Umnyombo weseli uqukethe ukugeza kwemolton cryolite(NA₃ALFF₆), ngokujwayelekile kusebenza aizinga lokushisa nokubandacishe ngo-950-970 ° C.Umsindona(Al₂o₃), kukhishwe kusuka ku-bauxite ore, kuyachithwa kulokhubusazana phakathiukugeza. Le khasiI-Carbon Anodeamabhlogo amiswe kubhavu ovela phezulu, ngenkathi kufakwa amaseli, futhiIzinto zekhabhoni(kaningii-graphiteamabhlogo), asebenza njenge-cathode (i-electrode engemihle).

Lapho unamandlaElectric yamanje(Imvamisa amakhulu ezinkulungwane zama-amperes) udluliswa esitokisini kusuka kuI-Carbon AnodeeKathode ngemolton cryolite I-electrolyte, theInqubo ye-electrolysiskuqala. OkuchithiweumsindonaDislociates ungenealuminiyamuna-umoya ohlanzekileion. Kukhokhiswa kahlealuminiyamuI-Ions uthuthela eKathode, lapho bathola khona ama-elektroni kanye nediphozithi njengencibilikisiweI-Aluminium Metal(Al³⁺ + 3E⁻ → AL). Ngasikhathi sinye, kukhokhiswe kabiumoya ohlanzekileion (O²⁻) ukuthuthela kuI-Carbon Anode. Lapha,I-Electrochemicalukusabela kwenzeka: Theumoya ohlanzekileuphendula ngekhabhoni ye-anode. Lokhu kusabela ngokuyinhloko amafomuI-Carbon Dioxide (I-CO2), yize abanyeI-Carbon Moxidekukhiqizwa futhi ngokuya ngemibandela. Ukusabela okulula okulula kakhulu e-anode yile: 2o²⁻ + c →I-CO2+ 4e⁻. Lokhu kusabela kudla iI-Carbon AnodeIndwangu, yehlisa kancane kancane kubhavu ngaphezulu kokusebenza kwayo okusebenzayo, okuvame ukuvelela amasonto ambalwa.

Iyiphi indima edlalwa yi-Coke ngaphandle kokudla okuluhlaza ekunyisweni kwe-aluminium?

LaphoUPetroleum Cokengokuyisisekelo kuyisisekeloimpahla eluhlazaOkweI-Carbon Anodeuqobo, ukuthonya kwalo kufinyelela ngaphezu kokumane kube yinqwabaimpahla esetshenzisiwe. Le khasiukuthayiphana-isimoyecockebabikezela kakhulu izakhiwo zokugcina kanye nokusebenza kwe-anode ngaphakathi kweUkubhema i-Alumininumiseli. Isakhiwo esakhiwe ngemuva kokukhangisa nokubhaka kuthonya izici ezibucayi ezifanaukuqina kukagesi, Amandla Omshini, kanye nokwenza umsebenzi ubhekeumoya ohlanzekilena-I-CO2. -Phezuluukubangelanisakubalulekile ukunciphisa ukulahleka kwamandla (i-voltage Drop) kuyo yonke i-anode, ukuthuthukisa ukusebenza kahle kwamandla kweukukhiqizwa kwe-aluminiuminqubo.

Ngaphezu kwalokho, thecockeIsakhiwo sithonya ukumelana kwe-anode kokubili-omshiniizingcindezi (ukuphatha, ukushaqeka okushisayo) futhiokuthakiweyoukuhlasela (oxidation ngomoya futhiI-CO2, ukusabela ngei-cryoliteizakhi). I-anode ehleleke kahle eyenziweikhwalithi ephezulu cockeuzoba phansiukudliwaamanani, okusho ukuthi i-anode engaphansi iyadingeka ngethani ngalinye lealuminiyamukukhiqizwa. Kuzokhiqiza futhi okuncaneokuhlangenekanye nothuli, kufaka isandla ekubusheni amabhodwe abushelelezi futhi kuncishisiweukugudlananoma izindaba zokusebenza. Ngakho-ke, ngenkathi kwesinye isikhathi kubhekwa njenge-aamalahleumthombo kwezinye izimboni, phakathiukukhiqizwa kwe-anode, cockeIngabe impahla enobunjiniyela kakhulu izakhiwo zabo ezilawulwa ngokwandisa konkeI-Aluminium Electrolysisinqubo. Ikhwalithi yayo iguge ukusebenza kahle nokuqina kweUkukhiqizwa okuyisisekelo kwe-aluminium.

Ungakwazi yini imininingwane ye-Aluminium Electrolysis kanye nokusetshenziswa kwe-anode?

Umnyomboubuchwephesheingomaneukukhiqizwa kwe-aluminiumihlala iyinqubo yehholo-héroult, yasungulwa ngokuzimela ngo-1886. IsimanjealuminiyamuamabheyesebenzisaAmaseli we-electrolytic amakhulu, alawulwa kakhulu ahlelwe ngochungechunge ("potlines"). Le khasiubuchwepheshekubandakanya ukudlula ngqo okuqondile-phathelene nogesiyamanje ngochungechunge walawa maseli. Iseli ngalinye lisebenza ngamanzi aphansi aphansi (azungeze ama-4-5 volts) kepha liphethe ama-amperage amakhulu (ama-100,000 kuya kwangama-500,000 amps). La mandla ashayelaInqubo ye-electrolysis, ehlukanisa amabhondi amakhemikhali aqinile ngaphakathiumsindona.

Le khasiukusetshenziswa kwe-carbon anodesyingxenye yalokhuubuchwepheshe. Njengoba kuchaziwe,I-Carbon AnodeAkuwona nje umqhubi; Kuyinto esebenzayo. Le khasii-electrolysistshekaumoya ohlanzekilekusuka ekuchitheniumsindona, nalokhuumoya ohlanzekileMasinyane uphendula nge-hot carbon ebusweni le-anode. Umkhiqizo wokuphendula oyinhlokoI-Carbon Dioxide (I-CO2), empeleni ukushisa iI-Carbon Anodekude nokusebenzisaI-Electrochemicalamandla kunokuba kuhlanganiswe ngokuqondile. Ngokweqiniso, ukukhiqiza i-1 kg yealuminiyamukudinga ukuqeda cishe ngo-0.33 kg wekhabhoni. Ekusebenzeni, ngenxa yokusabela eceleni (njengokushiswa komoya endaweni ephezulu eveziwe nokuphendula ngeI-CO2- The Boudouard Reaction C +I-CO2→ 2CCO) kanye nabanye ngokomzimbagqoka ukumelanaizingqinamba, inetha langempelaukudliwangokuvamile ephakeme, cishe ngo-0.40 kuye ku-0.45 kg weI-Carbon Anodenge-kg yealuminiyamukukhiqizwa. Lokhu kuyaqhubekaukudliwaIdinga okujwayelekileukubeka endaweniof anode, ukwenzaukukhiqizwa kwe-anodeumthamo ingxenye ebalulekile yanoma yikuphi okuhlanganisiwealuminiyamusmelter. Umgomo wokuthuthuka kwezobuchwepheshe okuqhubekayo ukunciphisa leli nethaukudliwaUkukala, ukuthuthukisa ukusebenza kwamanje, kanye nokusetshenziswa kwamandla okuphansi.

Yini eyenza i-anodode esezingeni eliphakeme yokubhema kwe-aluminium?

A ikhwalithi ephezulu I-Carbon Anode (impahla ye-anode) kuchazwa isethi yezakhiwo ezithile zomzimba nezamakhemikhali ezibalulekile ukuze zisebenze kahle futhi zizinzileUkubhema i-Alumininum. -Ehlile-gesiUkumelana kubaluleke kakhulu; I-anode kumele iqhube ama-currents amakhulu ngokudonsa okuncane kwe-voltage ukuze kulondolozwe amandla. Okuphezulu okusobalaincekusanafuthi kubucayi - i-anode ye-denser ngokuvamile isho i-roweryity ephansi, inciphisa ukuvumelanisa nomoya futhiI-CO2, okuholela ephansiukudliwaamanani nokuphila okude. Kuhle ngokuncomekayoAmandla Omshinikanye nokumelana nokushaqeka okushisayo kuyadingeka ukumelana nokuphatha, izingcindezi zokufaka zibe kushisamolton cryoliteukugeza, kanye nokusebenzaizinga lokushisa nokubandaimijikelezo ngaphandle kokuqhekeka noma ukuchitheka ngokweqile.

Ngaphezu kwalokho, ubumsulwa bubalulekile. Ukungcola kuimpahla ye-anode, ikakhulukazi izinto ezifana nesibabule, i-silicon, i-iron, i-vanadium, ne-nickel isuka kuUPetroleum CokenomaI-Coal Tar Pitch, ingangena kuI-molten aluminium, kuthinta ubumsulwa bawo bokugcina kanye nezakhiwo. Ukuvuselelwa okuphansi kuya emoyeni futhiI-CO2Emazingeni okushisa okusebenza nakho kuyinto efiselekayo ukunciphisa okungelona ele-electrochemicalukudliwa. Ukufana kubalulekile - izakhiwo ezingaguquki kulo lonke i-anode block kanye ne-anode eyodwa kuya kwelandelayo qinisekisa ukusebenza okubonakalayo nokusebenza kweseli ezinzile. Ukuthola lokhu kungaguquguqukiikhwalithi ephezulukudinga ukulawula okuthembekile ngaphezulu kweimpahla eluhlazaUkukhetha, iindlela yokulungiselela, nazo zonke izinyathelo zeukukhiqizwa kwe-anodeinqubo. Abahlinzeki bathi bagxile kakhulu kulawa mapharamitha wekhwalithi ukuze ahlangabezane nezidingo ezifunwayo zeimboni ye-aluminium. -KwethuUkusebenza okuphezulu kwe-Anode Carbon BlockIsibonelo sokuzibophezela kwikhwalithi.

Yiziphi izinselelo ezinkulu kanye nokukhathazeka kwemvelo ekukhiqizweni kwe-carbon anode nokusetshenziswa?

Ngenkathi kubalulekile, ukukhiqizwa nokusetshenziswa kweI-Carbon AnodeYethula izinselelo ezinkulu, ikakhulukazi maqondana nomthelela wezemvelo. Ukukhathazeka okuyinhloko ngesikhathiI-Aluminium Electrolysisyi-ukuphumayamagesi abamba ukushisa (Uhlobo). Ukusabela okuqondile kweI-Carbon Anodene-umoya ohlanzekilekukhiqiza inani elikhulu leI-Carbon Dioxide (I-CO2), okukhuluigesi ebamba ukushisa. Kuwo wonke amathani wealuminiyamukukhiqizwa, cishe amathani ayi-1.5 weI-CO2zikhiqizwa kusukela ku-anodeukudliwa. Ngokwengeziwe, ngaphansi kwenqubo ethile yezimo ezicasulayo (i-alumina ephansi), i-pumpluorocarbons (PFCS), ama-ghgs anamandla amakhulu, angakhiwa. Amandlaukudliwauqobo, kukhiqizwe kakhulu kusuka kumafutha emifino ezifundeni eziningi, kunomthelela ngokungaqondile kwikhabhoniumaka wonyawo enhlabathini.

Le khasiukukhiqizwa kwe-anodeInqubo futhi inezici zezemvelo. Ukubhaka okumaka kungakhipha ukungcola uma kungalawulwa kahle, kufaka phakathi i-sulfur oxides (kusuka ku-sulfur kucocke),, ama-nitrogen oxides, udaba lokuhlanganisa, kanye namakhompiyutha ajwayelekile aphilayo avela ku-pitch mainder. UkuphekaUPetroleum Cokena-I-Coal Tar PitchKudinga ukuphathwa ngokucophelela ngenxa yokukhathazeka okungaba khona kwezempilo kanye nokukhathazeka kwezemvelo okuhambisana nothuli kanye namakhompiyutha athile afana ne-polycyclic aromatic hydrocarbons (ama-pahs) emuncumu. Ukuqinisekisa ukuguquguqukaimpahla eluhlazaIkhwalithi, Ukuphathaizibi(Njengokusebenzisa potter), nokulawulaukuphumaKuyo yonke lempilo izinselelo eziqhubekayo ze-aluminiyamuimboni. Ukucinga kwezinto zokwakha ezingconogqoka ukumelanakanye nomthelela oncishisiwe wezemvelo uyaqhubeka. Izindaba ezinjengokuqhekeka kwe-anode noma ukwehluleka ngaphambi kwesikhathi ngenxaukugqwalanomaIzakhiwo zemishiniFuthi amele izinselelo zokusebenza ezithinta ukusebenza kahle nezindleko.

Ngabe ubuchwepheshe buhlanza kanjani ukuphuma kwenqubo yokukhiqiza ye-aluminium?

Le khasialuminiyamuImboni ikuphishekela okuhlukahlukeneubuchwephesheizindlela eziyasukaImvelo yayoumaka wonyawo enhlabathini, ikakhulukaziUhlobo ukuphuma. Imizamo ebalulekile igxile ekuthuthukiseni ukusebenza kahle kwamandla kwenqubo yehholo-Héroult uqobo. Ukulawulwa Kwenqubo Engcono, Imiklamo Yeseli Ethuthukile, kanye nokuphathwa okuthuthukile kwe-Thermalukunciphisa kakhuluamandla adingekayo ngethani ngalinyealuminiyamu, ngaleyo ndlela yehlise ngokungaqondileukuphumaUma umthombo wamandla we-fossil-fuel kusekelwe. Ukunxusa ikhwalithi ye-anode (Njengama-electrodes ethu we-graphite eyenziwe nge-coke ethile) Ibamba iqhaza, lingconoukubangelanisafuthi phansiukudliwaAmanani anikela ekuzuzeni kahle. Izinhlelo zokulawula nokulawula okuthuthukisiwe zisiza ukuvikela imiphumela ye-anode, ngaleyo ndlela kunciphise kakhulu i-PFCukuphumaizehlakalo. EthwebulaI-CO2Kusuka kuSmelter off-amagesi kuyahlolwa, yize kuveza izinselelo ezibalulekile zobuchwepheshe nezomnotho.

Injongo enkulu yesikhathi eside ukuthuthukiswa kwe-inert anodeubuchwepheshe. -Ngafani na-I-Carbon AnodelokhokudliwaukukhiqizaI-CO2, u-inert anodes wayezophatha ugesi futhilulashwahlela phansiukukhishwa kweumoya ohlanzekilenjengegesi (O2) esikhundleni sokuzabela. Izinkampani ezithandaUhlobo(ngokusebenzisa i-Elysis Joint Venture) benza ama-strides kule ndawo. Uma uphumelele futhi usebenze ngokuhweba, i-anodode ye-inert angashintsha ngokuyisisekeloukukhiqizwa kwe-aluminium, ukuqeda okuqondileI-CO2 ukuphumakusuka esitokisini se-electrolysis. Olunye ucwaningo luhlola okunyei-electrolysisIzinqubo noma inoveliIzinto ze-Carbonaceouslokho kungahlinzeka ngokuvuselelwa okuphansi noma ukunika amandla okuhlukileokuthakiweyoizindlela. Lezi zithuthuka zezobuchwepheshe zihlose uku-ukunciphisa okupheleleumthelela wezemvelo futhi uqinisekise ukuqina kwesikhathi eside kwealuminiyamuukukhiqiza.Ukuphuma kungakwaziOkungaba khona ukunqunywa ngokumangazayo nalobu buchwepheshe obuzayo.

Yini okufanele yenziwe ngokuthengwa kwempahla yokuthenga?

Ukuze uthole izikhulu zokuthengwa kwempahla njengoMark Thompson, SourcingI-Carbon AnodeKubandakanya ngempumelelo ikhwalithi yokulinganisa, izindleko, kanye nokwethenjwa. Njengoba kunikezwe ukuthi ama-anode akhonakudliwe ngesikhathi senqubo ye-electrolysis, ukunikezwa kokuhlinzekwa okuthembekile akuxoxiswanga. Ngaphandle kwamanani entengo yokuncintisana, ukugxila okuyisisekelo kufanele kuqhubekeisimo esivumelanayo. Lokhu kusho ukuqinisekisa izinqubo zokulawula ezisezingeni lomhlinzeki, kusukaimpahla eluhlazaukuhlolwa (UPetroleum Coke, pitch) ekuhlolweni kokugcina kwe-anode. Ukucela kanye nokuqinisekisa isitifiketi (e.g., ISO 9001) futhi kuningiliziweinto uqobo lwayoAmashidi acacisa abalulekile. Musa nje ukuthatha izitifiketi ngenani elifanele; Qonda izindlela zokuhlola namapharamitha.

Ukwethenjwa kufinyelela ekuhlelweni kwezinto nokuxhumana. Ukubambezeleka kokuhanjiswa kwe-Anode kungamisa imigqa yokukhiqiza, kubangele ukulahleka okukhulu kwemali. Hlaziya irekhodi lethrekhi yomhlinzeki ngokulethwa kwezikhathi ngesikhathi kanye namakhono abo okudla, ikakhulukazi ukuthunyelwa kwamanye amazwe ezifundeni ezinjenge-USA noma iYurophu. Ukuxhumana okucacile, okusebenzayo nakho kubalulekile. Ukubhekana ngqo nommeleli onolwazi oluvela efektri, njengami, allen, kusuka kuIfektri ye-electrode ye-professional graphite, ingahle iqondise izingxoxo futhi ixazulule izingqinamba ngokushesha kunokuhamba phakathi kwabalamuli abaningi. Ukuxhaswa kwezobuchwepheshe, noma ngabe umthengi engeyena unjiniyela, ubalulekile. Umphakeli omuhle kufanele akwazi ukuxoxa ngokwenza i-anode, izingcindezi ezingabakhona ezingaba khona ezihlobene nomkhiqizo wazo, futhi achaze ukuthi zazo kanjaniimpahla ye-anodeizakhiwo (incekusana, ukubangelanisa, Amandla Omshini) Qondanisa nezidingo zokusebenza komthengi. Okokugcina, qinisekisa izindlela zokukhokha ezisobala neziphephile ziyatholakala. Ukwakha ubudlelwano besikhathi eside nomenzi odumile abaqonda izimfuno zealuminiyamuImboni ivame ukuba necebo elihle kakhulu.

Ukuthathwa Key:

- I-Carbon Anodekuyinto ebalulekile enqubweni yehholo-héroult yeukukhiqizwa kwe-aluminium, esebenza njengabaqhubi kanye nama-eckants.

- Ukukhiqizwa kwe-anodekubandakanya ukucubungula ngokucophelelaUPetroleum Cokena-I-Coal Tar PitchI-Binder, ilandelwe ngokwakha nokuphezulu-izinga lokushisa nokubandaukubhaka.

- Ikhwalithi yeAma-Raw material, ikakhulukaziCalcated Petroleum Coke, kuthonya ngqo ukusebenza kwe-anode (ukuqhutshwa, ubukhulu, amandla, ubumsulwa) kanyeukudliwaamanani.

- Kudliwa ama-anode e-carbonngesikhathii-electrolysisNjengoba ikhabhoni ibhekana nayoumoya ohlanzekileukusukaumsindona, ngokuyinhloko ukwakhaI-CO2.

- Amapharamitha wekhwalithi asemqoka afaka phakathi okuphansi-gesiUkumelana, Okuphezuluincekusana, kuhleAmandla Omshini, ukuhlanzeka okuphezulu, nokuvuselela okuphansi.

- Izinselelo ezinkulu zifaka ukuphathaI-CO2nezinyeukuphuma, Amandlaukudliwa, kanye nokuqinisekisa ukuguquguqukaimpahla eluhlazaukuhlinzekwa.

- UbuchwephesheUkuthuthuka Kugxile ekuthuthukiseni ukusebenza kahle, ukunciphisaukuphuma, futhi ethuthukisa ama-anonode aguqula umdlalo.

- Lapho sidonsa, gxila kwikhwalithi engaguquki, ukuthembeka kwabahlinzeki (izinto, ukuxhumana), ukuqinisekiswa okuqinisekisiwe, ukusekelwa kwezobuchwepheshe, nokuthengiselana okusobala.

Isikhathi sePosi: 04-07-2025