Ama-electrodes we-graphite amaqhawe angasebenzi kaMuntu wensimbi wanamuhla, ikakhulukazi ngaphakathi kweUgesi we-arc kagesi(EAF). Lezi zinto ezibonakala zilula zidlala anindima ebaluleke kakhulu, ukwenza njengoba umsele wokukhuluamandla kagesikudingekancibilikisa klabuthainsimbi futhicolainensimbi esezingeni eliphakeme. Ukuqonda umsebenzi, izinhlobo, nokubaluleka kweI-Graphite Electrodekubalulekile kunoma ngubani obandakanyeka kuwoEaf Stebilemaking, Kusuka kuma-Operacers Reachers afana noMark Thompson kochwepheshe bokuthengwa kwempahla abafuna izinto ezinokwethenjelwa, ukusebenza okuphezulu. Le ndatshana ishona ngokujulile emhlabeni weAma-electrodes we-graphite e-arc kagesiizimpande, ukuhlola ukuthi kungani zinjalo aisakhi esibalulekile, basebenza kanjani, amamaki ahlukile atholakalayo (Hpna-Uhp), futhi yiziphi izinto eziqinisekisa ukusebenza kahle nokusebenza kahle ekufuneniinqubo yokwenza insimbi. Sizohlola ukuthi kungani saboamandla aphezulu wemishinikanye nezakhiwo ezihlukile zizenza zibalulekile kulokhuokushisa okuphezuluIsicelo.

Ngabe yini ngempela isithando somlilo we-arc (eaf) futhi ihlukile kanjani ngezindlela zendabuko?

AUgesi we-arc kagesi(EAF) imelela intuthuko ebalulekile ekukhiqizeni insimbi kuqhathaniswaIzindlela Zendabukonjengesisekelo se-oxygen eyisisekelo (bof) esetshenziswa ngokuyinhlokoiron ore. I-EAF empeleni iyimbiza enkulu, enamandla ebiwombisayo esebenzisayoamandla kagesiukuguqulaklabuthaI-Metal - isukela ezimotweni ezindala nasezintweni ezisetshenziswayo eziya ezimboni zezimboni - zibe ngensimbi entsha. Le nqubo inikeza izinzuzo eziningana, ikakhulukazi ukuthembela kwalo ku-Repycledimpahla eluhlaza (isiketa), okunciphisa kakhulu isippitho semvelo esiqhathaniswa nezimayini kanye nokucubungula i-Virtual Iron Ore. Ama-eafs ayaziwa ngokuguquguquka kwawo, okuvumelaabenzi bensimbiukukhiqiza amabanga ahlukahlukene ensimbi, kufaka phakathi okukhethekileingxubevangeama-steel.

Umehluko oyisisekelo ulele kuumthombo wamandlafuthi kwamabanga aphansiimpahla eluhlaza. Ngenkathi ithola yendabuko yendabuko ithembela ekuphendukeni kwamakhemikhali kwe-coke ne-iron ore atUkushisa okuphezuluukukhiqiza insimbi encibilikisiwe (esehliswe ngensimbi),Ugesi we-arc kagesiisebenzisa amandla aphezuluI-Electrical yamanje, Kuthunyelweama-electrodes we-graphite, ukuzekhiqiza ukushisa okukhulu- Sikhuluma amazinga okushisa afinyelela ku-1,800degree Celsius(ngaphezulu kuka-3,000 Fahrenheit) nangale kwalokho - ukuncibilika ngqoisikena sensimbi. Le ndlela ngokuvamile ishesha esikalini esithile sokukhiqiza futhi inomthelela kuyoindawo eluhlaza ophansiUkukhishwa kwegesi, ukwenzaEaf Stebilemakingindlela eqhubekayo yeukukhiqizwa kwensimbiezimweni eziningi. I-Powerhouse yokuphinda isebenze kabusha, iguqula i-Metal izolo ibe yingqalasizinda yakusasa.

Kungani i-lectrode ye-graphite Inhliziyo yenqubo ye-EAF?

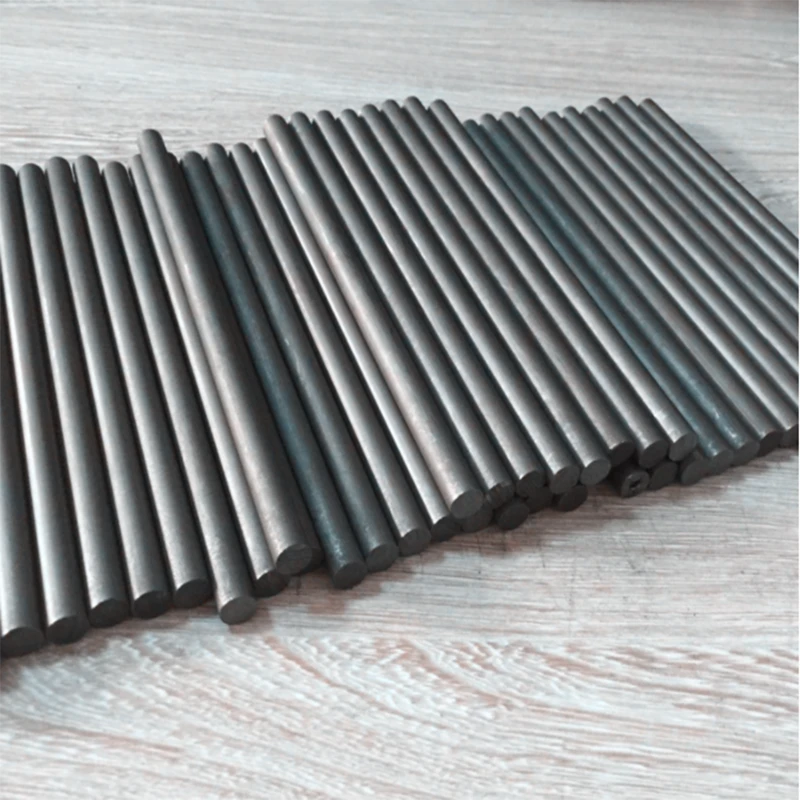

Le khasiI-Graphite Electrodekubaluleke ngempela kuUgesi we-arc kagesi. Ngaphandle kwalo, yonke inqubo umane nje ngeke isebenze. Umsebenzi wayo oyinhloko ukwenza i-massiveI-Electrical yamanjekudingekile ukuzedala i-arc kagesiphakathi kweI-electrodeAmathiphu kanye nenkokhiso yensimbi (klabutha) Ngaphakathi kwesithando somlilo. Leliucezu lwesiyingiungumthombo weukushisa okukhuluokudingekayoncibilikisale khasiisiketa. Cabanga ngeI-Graphite ElectrodeNjengesici esigabeni esikhulu, i-kettle enamandla amakhulu, kepha esikhundleni samanzi abilayo, kuyancibilika amathani wensimbi.Ama-electrodes we-graphite abucayiNgoba banenhlanganisela eyingqayizivele yezakhiwo ezilungele kahle le ndawo enokhahlo.

Okokuqala, i-graphite iqhosha ngendlela emangalisayoUkusebenza Kagesi Okuphezulu, ukuvumela ukuthi kuphathe imisinga enkulu (amashumi ezinkulungwane zama-amperes) ngempumelelo nge-minimalamandla kagesiukulahleka (ukumelana okuphansi). Okwesibili, ihlukileimpambaUkumelana futhiamandla aphezulu wemishini, ukunika amandlaukumelana namazinga okushisa aphezulukanye nokushaqeka okushisayo okwenziwe ngui-arc kagesikanyeinsimbi encibilikisiweukugeza ngaphandle kokululaza ngokushesha noma ukwephula. Ezinye izinto zokwakha zivele zigasele noma zigaxe ngaphansi kwezimo ezinjalo. Le khasiIndima ye-graphite electrodesinwebeka ngaphandle kokuqhuba ugesi nje; bayizinto ezisebenzayoI-electrodeyenzelwe ngqo izimfuno ezedlulele zeElectric arc ruc funmakinginqubo. Bona, ngaphandle kwehaba, umnyombo osebenzayo lapho i-EAF isebenza khona.

Ngabe ama-electrodes we-graphite asebenza kanjani ngaphakathi kwesithando se-arc kagesi? (Gxila ku-arc)

Umlingo weUgesi we-arc kagesikwenzeka laphoama-electrodes we-graphitekwehliswe ebhekiswe kwicalaisikena sensimbi. I-voltage ephezulu, ephezulu-ampareElectric yamanjekudluliswa ku-I-electrodeikholomu. Njenge-I-electrodeAmathiphu asondela ekushajaneni kwensimbi, igebe lomoya phakathi kwalona ama-Ionizes, adala ukukhishwa kukagesi okuqhubekayo -i-arc kagesi. Leliucezu lwesiyingiempeleni i-bolt elawulwa yombani, ekhulula amanani amakhulu wamandla ngokuyinhloko ngesimoukushisa. Le khasiUkudlula kwamanje kagesikusuka koyedwaI-electrode, ngokusebenzisaucezu lwesiyingi, kuklabutha, kungenzeka ngenyeucezu lwesiyingikomunyeI-electrode(kuya ngokusetha), ukuqeda umjikelezo.

Le nqubo yei-arc kagesiUkwakheka kuyaqhubeka ngesikhathi sesigaba sokuncibilika. Le khasiukushisa okukhulu(kuvame ukwedlula i-3000 ° Cngaphakathi kwe-arc kagesingokwayo) kuyakhanya kuklabutha, kwenza ngokusheshancibilikisa. Le khasiUkuziphatha kwe-electrodesHhayi njeYamanje esithandweni somlilo, kodwa futhi futhi ukuphathaucezu lwesiyingiUkuqina kanye nesikhundla sokuqinisekisa ukuncibilika okusebenzayo. Izinhlelo ezi-control ezinobuchwepheshe zilungisa isikhundla seI-electrodeamakholomu njalo ukuze alondoloze kahleucezu lwesiyingiubude nokufakwa kwamandla. Lokhu kulawulwa, amandla aphezuluucezu lwesiyingi, kugqugquzelwa ukuqinaI-Graphite Electrode, lokho kwakha isisekelo seukujikelezakuUgesi we-arc kagesi, enika amandla ukuguqulwa okuqinileklabuthaku-insimbi encibilikisiwe.

Yimiphi imisebenzi eyinhloko yama-electrodes we-graphite ku-Eaf Stebilemaking?

Le khasiImisebenzi ye-graphite electrodeskuUgesi we-arc kagesibahlukahlukene futhi babucayi ngokuphumelelaUkusebenza Komthandela. Ngenkathi umsebenzi oyinhloko waziwa kahle, izindima eziningana ezibalulekile ziqokomisa ukubaluleka kwazo:

- Eqhuba ugesi wamanje:Lona umsebenzi osobala kakhulu. Le khasiI-electrodeIsebenza njengendlela yendlela enkuluI-Electrical yamanjeedingeka ukunika amandla isithando somlilo. -AboUkusebenza Kagesi OkuphezuluIqinisekisa lokhu ngempumelelo.

- Edala i-arc encibilikayo:Le khasiI-electrodeamathiphu akhona laphoi-arc kagesiishaywe. Kumele bamelane neamazinga okushisa aphezulufuthi amabutho aqagelayo eucezu lwesiyingiuqobo kuyakhiqiza ukushisa okukhulunjalo. Ikhono leama-electrodes we-graphite ukukhiqizaleliukushisa kudingekile ukuncibilikale khasiklabuthakubalulekile.

- Kudluliswa ukushisa:Le khasiukushisakukhiqizwa yiucezu lwesiyingiidluliselwa ku-klabuthakhokhisa ngokuyinhloko ngemisebe. Le khasiI-electrodeIsikhundla kanye neucezu lwesiyingiukuqina kwethonya lokhu kusebenza kahle kanjaniukushisaUkudlulisela kwenzeka, kunomthelela othinta ngokuqinile isivinini nokusetshenziswa kwamandla.

- Ukumelana nezimo ezinzima:Le khasiI-electrodekumele ubekezelele hhayi kuphelaUkushisa okuphezuluyeucezu lwesiyingina-insimbi encibilikisiwekodwa futhi nokuhlaselwa kwamakhemikhali kusukauhlobo olukhulu oluhle(Ukungcola okubilisiwe) kanye nokuxineka ngokomzimba ngesikhathi sokusebenza (njengekhonoklabuthaCave-ins). -Aboimpambaukuqina kanyeamandla aphezulu wemishinizibalulekile lapha.

- Ukwenza lula ukucwilisa:Ngenkathi ukuncibilika kubalulekile,ucezu lwesiyingifuthi idlala indima kucolaIsiteji, sisiza ukususa ukungcola futhi silungise amakhemikhali weinsimbi encibilikisiweNgokulawulwaukushisaUkufaka kanye nemiphumela evusa amadlingozi eyenziwe nguucezu lwesiyingi.

Empeleni,I-Graphite Electrodeakuyona nje ucingo; Kuyithuluzi elisebenza kakhulu elenzelwe ukuletha amandla, dala ukuncibilikaucezu lwesiyingi, futhi usinde enye yezindawo zezimboni ezabiwe kakhulu emhlabeni. Le khasiAma-electrodes esithandweni sikagesi se-arcUkusebenza ngempela kukhona ama-WorkHerskuncibilike insimbi.

Yini eya ekwenzeni i-electrode yokusebenza ephezulu? (Izinto zokwakha kanye nokukhiqiza)

Ukudala aI-Graphite Electrodeokwazi ukwenza ngokuthembekile kuUgesi we-arc kagesikuyinqubo eyinkimbinkimbi, enezigaba eziningi ezibandakanya ikhethwe ngokucophelelaAma-Raw materialkanye namasu okukhiqiza aqondile. Izithako eziyinhloko ziyikhwalithi ephezuluUPetroleum Cokena-inaliti coke. Inaliti coke, nge-crystalline yayo enkulu, isakhiwo esinjengesonali, sibaluleke kakhulu ekusebenzeni okuphezuluI-electrodes(ikakhulukaziI-UHP GraphiteAma-electrodes) ngoba ihlinzeka ngokuhle kakhuluukuqina kukagesi, ukunwebeka okuphansi okushisayo, kanye nokumelana okuphakeme kokushaqeka kwe-thermal futhioxidation.

Inqubo ihlanganisa:

- Ukuxuba:Amanani alinganiswe ngokufanele aqokiweUPetroleum Coke, inaliti coke, futhi i-coal tal pitch bilinder ixutshwe emazingeni okushisa aphakeme.

- Kwakha (ukukhishwa noma ukubumba):Ingxube yabe sesungulwa esimweni se-cylindrical of theI-electrode, imvamisa ngokukhishwa ngosayizi ojwayelekile.

- Ukubhaka:"Okuhlaza"I-electrodeKubhakwe kancane kancane esithandweni esikhulu ngaphezulu kwamasonto ambalwa ku-Carboneze i-Binder bese udale isakhiwo esinamandla sekhabhoni.

- Ukufakwa kabusha:Ukwandisa ubuntu, amandla, kanye nokwenza, okubhakweI-electrodeImvamisa ifakwa nge-pitch ngaphansi kwengcindezi bese i-re-ebhakwe kabusha. Lesi sinyathelo singaphindwa.

- Ukuhlunga:Lesi yisinyathelo esibucayi. Le khasiI-electrodeifudunyezwa kakhuluamazinga okushisa aphezulu(esondela ku-3000degree Celsius) esithandweni esikhethekile sikagesi. LeliukusakazaInqubo ihlele kabusha ama-athomu e-carbon ekwakhekeni kwe-crystalline ye-graphite, edlulisela izakhiwo ezifiselekayo ezifana nokuqhutshwa okuphezulu futhiUkumelana nokushisa. Le khasiIzinga lokushisa le-graphitizationkulawulwa ngokucophelela.

- Imishini:Ekugcineni, i-grafitisI-electrodeukunemba kwenziwe ngokuluci ukudala amasokisi ane-threaded emaphethelweni, okuvumela umuntu ngamunyeI-electrodeizingxenye ezizohlanganiswa ndawonye zaba amakholomu amade ukuze asetshenziswe ku-Eafs.

Le nqubo yokucophelela iqinisekisa owokugcinaI-Graphite Electrodeunazo izici ezidingekayo -ukumelana okuphansi, ubuningi obuphezulu, okuhle kakhuluAmandla Omshini, kanye nekhono lokwenza ngaphansi kwezimo zokujezisaNgaphakathi kwesithando somlilo. Njengomnikazi wefektri onemigqa engu-7 yokukhiqiza, mina, u-Allen, angafakazela ukucaciswa okudingekayo esinyathelweni ngasinye ukuzekhiqiza insimbi esezingeni eliphakemeizakhi ezinjengalezi.

Ukudicilela phansi izinhlobo zama-electrodes we-graphite: RP, HP, ne-UHP echaziwe

Akubona bonkeama-electrodes we-graphitezidalwe zilingana. Ngokuvamile zihlukaniswaizinhlobo ezintathukususelwa kwizabelo zabo namazinga wamandla enzelwe ukuphatha kuUgesi we-arc kagesi. Ukuqonda la mabanga kubalulekile ekufaniseniI-electrodekuya kokuqondileUhlobo lwesithandonezidingo zokusebenza.

-

Amandla we-graphite ajwayelekile (RP) we-graphite:

- Ama-Raw material:Ngokuyinhloko enziwe ebangeni elijwayelekileUPetroleum Coke.

- Density yamanje:Yakhelwe phansiukuqina kwamanjeIzicelo (Ngokuvamile <18 A / cm²).

- Izicelo:Isetshenziswe incane noma ngaphezuluEafs, imvamisa ngokuncibilika okuyisisekeloisiketanoma ngaphakathiIzimfanelo zamaLadingokucwengisisa, futhi kwesinye isikhathi kui-arc engenisiweIzakhiwo zeFerrolAlloy Production. -KwethuAmandla we-graphite ajwayelekile we-graphiteilungele lezi zinhlelo zokusebenza.

- Izici:Izindleko eziphansi, amandla alinganiselayo nokuqhutshwa okuqhathaniswa namabanga aphezulu. AI-Rp Graphite Electrodekuyindlela yokungena.

-

Amandla aphezulu (hp) i-graphite electrode:

- Ama-Raw material:Isebenzisa ikhwalithi ephezuluUPetroleum Coke, kwesinye isikhathi nengxenye yeinaliti coke.

- Density yamanje:Ilungele ukuphakamaukuqina kwamanjeUkusebenza (imvamisa 18-25 A / CM²).

- Izicelo:Isetshenziswe maphakathi nendawo emandleni amakhuluEafsingomaneinqubo yokwenza insimbiedinga ukuncibilika okusheshayo kuncibilika kune-RP kuvumela.

- Izici:Okunikezwa kangconoukuqina kukagesi, Ukumelana nokushisa, futhiAmandla Omshinikuna-RpaElectrodes. Ukukhetha okuthembekile kwezinga eliningiEafs. Bheka kwethuI-electrode ephezulu yamandla we-graphiteIzinketho.

-

I-Ultra-High Power (UHP) i-graphite electrode:

- Ama-Raw material:Ngokuyinhloko eyenziwe ngeprimiyamuinaliti coke.

- Density yamanje:Yakhelwe izicelo ezifunwa kakhulu nge-High Ephakeme kakhuluukuqina kwamanje(> 25 A / CM²).

- Izicelo:Kubalulekile ekukhiqizeni kwanamuhla, okuphezuluEafsUkuhloselelwa kokukhishwa okuphezulu nokusebenza kahle. Wawuvamisencibilikisaamavolumu aphezulu weklabuthangokushesha.

- Izici:-Ngconoukuqina kukagesi (ukumelana okuphansi), ukumelana okuhle nokushaqeka kwe-thermal kanyeoxidation, ephezulu kakhuluAmandla Omshini. I-UHP GraphiteAma-electrodes avumela izinsizakusebenza ukuze zisebenze emazingeni e-Peak Power, kunciphisa izikhathi zokuthepha. Iprimiyamu yethuI-Eltra-High Power Graphite Electrodekubhekwe ngale misebenzi efunwayo.

Ukukhetha okulungileI-electrodeThayipha (Rpa, Hp, nomaUhp) kubalulekile ukwenza kahleUkusebenza Komthandela, Ukuphatha ukusetshenziswa kwamandla, nokulawula izindleko zokukhiqiza jikelele. Usebenzisa i-I-electrodeAyikalwanga amandla weFholane kungaholela ekuhlulekeni ngaphambi kwesikhathi nasekusebenzeni kahle.

Ngabe ikhwalithi ye-electrode ithonya ukusebenza kwe-EAF ukusebenza kanye nezindleko eziphelele?

Izinga leI-Graphite Electrodeisetshenziswe kuUgesi we-arc kagesiunomthelela oqondile futhi obalulekile ekusebenzeni kwesithando somlilo kanye nezindleko eziphelele zokukhiqizwa kwensimbi. Ukuze uthole izikhulu zokuthengwa kwempahla njengoMark Thompson, ukuqonda lesi sixhumanisi kuyisihluthulelo sokwenza izinqumo ezisebenzayo ezingabizi kahle. Ikhwalithi ephansiI-electrodeskungahle kubonakale kushibhile ngaphambili, kepha kuvame ukuholela ezindlekweni eziphakeme kakhulu ngenxa yamanani amaningi okusetshenziswa (ukwephula noma i-oxidizing ngokushesha), izikhathi eziphansi (ngenxa yokuphazamiseka okungenzeka), nokuphazamiseka okungenzeka okusebenzayo.

Ikhwalithi ephezuluama-electrodes we-graphite, kubonakaliswa ukwakheka okufanayo, ukuqina okuphezulu,ukumelana okuphansi, okuhle kakhuluimpambaukumelana okushaqisayo, futhiamandla aphezulu wemishini, Nikela kwi:

- Ukusetshenziswa kwe-elektrode okuphansi:Bayamelana neamazinga okushisa aphezulukanye nokucindezela kwemishini okungcono, okuholela esikhathini esideImpilo YenkonzoFuthi ama-graphite amancane adliwe ngethani lensimbi elikhiqizwayo.

- Ukusebenza kahle kwamandla okuthuthukile:-Ngconoukuqina kukagesikusho okuncaneamandla kagesiichithwa njengeukushisangaphakathi kwe-I-electrodeuqobo, ukuvumela amandla amaningi ukufinyelelaucezu lwesiyingina-ncibilikisale khasiklabuthaNgokushesha.

- Ukukhiqiza okwandayo:Indlu yamahhashiucezu lwesiyingiukusebenza nokunciphisa isikhathi sokuphumula ngenxaI-electrodeUkwephulwa noma ukwehluleka ngaphambi kwesikhathi kuholele ezikhathini ezimfishane ze-Tap-to-Tap kanye nokuphuma kwesithando somlilo esiphakeme.

- Ubungozi obuncishisiwe bokuqhekeka:-NgconoAmandla Omshiniinciphisa ubungozi beI-electrodeAmakholomu aphuka ngesikhathi sokusebenza, okungadala ukubambezeleka okubizayo kanye nomonakalo wokulimala komthamo.

- Ukusebenza Okungaguquki:-QothoI-electrodeshlinzeka ngokuziphatha okubikezelayo okuncibilikayo, okuvumela ukulawulwa kwenqubo engcono nokusizakhiqiza insimbi esezingeni eliphakemenjalo.

Ngakolunye uhlangothi, ukungahambelani noma okuphansi-ikhwalithiI-electrodeskungaholela ekuqhekekeni kaningi, ukusetshenziswa kwamandla okuphezulu, imijikelezo yokuncibilika engalindeleki, futhi yandaukushushuluzaIzinkinga, ekugcineni zishayela izindleko ngethani lensimbi. Ngakho-ke, ukutshala imali ngekhwalithiama-electrodes we-graphitekubalulekile ukuthola kahle futhi kwezomnothoEaf Stebilemaking.

Yiziphi izinselelo ezibalulekile ezenziwa ama-steelmaker abhekana nama-electrodes we-graphite ku-EAF Operations?

Isebenza iUgesi we-arc kagesiiza nezinselelo zemvelo, futhi eziningana zalezi zihlobene ngqo neama-electrodes we-graphite. Abasebenza be-Stermaker kanye nabasebenza e-Furrace bahlala belwela ukunciphisa lezi zinkinga ukuze baqinisekise ukukhiqizwa okubushelelezi nokusebenzayo. Inselelo enkulu eyodwaukusetshenziswa kwe-electrode. Kusetshenziswa ama-electrodes we-graphitephezulu ngesikhathi senqubo ngokusebenzisa i-tip sublimation (Vaporization ngenxa yeucezu lwesiyingi'ukushisa okukhulu), ngaphezuluoxidation(Ukuphendula nge-Air And Isithando Semagesi), kanye nokuphuka kwemishini noma ukuchitha. Ukuphatha nokunciphisa lokhu kusetshenziswa kubalulekile ukuze kulawulwe izindleko.

Enye inselelo ebalulekile, imvamisa iphuzu lobuhlungu abathengi abanjengoMark, liqinisekisa livumelanaI-electrodeikhwalithi nokuthembeka. Ukuhlukahluka kuI-electrodeizakhiwo zingaholela ekusebenzeni okungalindelekile, kungazinzileucezu lwesiyingiUkuziphatha, kanye nengozi eyengeziwe yokuqhekeka. Lokhu kugcizelela ukubaluleka kokuthola abakhiqizi abadumile ngokulawulwa kwekhwalithi okuqinile. Ukuphatha nokujoyinaI-electrodeizingxenye nazo zidinga ukunakekelwa; Ukuhlangana okungafanele kungaholela ekumelaneni kukagesi okuphezulu ekuxhumekeni, kukhiqize okweqileukushisafuthi kungenzeka kwabangela ukwehluleka okuhlangene nomaI-electrodeukuqhekeka. Ngaphezu kwalokho,I-electrodeUkuqhekeka ngesikhathi sokusebenza kuyikhanda elikhulu, okubangela isikhathi sokuphumula esiphambili, ukulimala okungaba khona esithandweni somlilo, kanye nokulahlekelwa ukukhiqizwa. Ekugcineni, ukuguquguquka kwentengo yemakethe yeama-electrodes we-graphite, eqhutshwa nguimpahla eluhlazaIzindleko (ikakhulukaziinaliti coke) kanye nokuhlinzekwa komhlaba jikelele / funa, kunezela enye isendlalelo sobumbano ekuthengeni kanye nokuphathwa kwezindlekoEafs.

Njengomthengi (njengoMark), ungaqinisekisa kanjani ukuthi uthola u-Electrodes othembekile futhi osezingeni eliphakeme?

Kwabanikazi benkampani kanye nabaphathi bokuthengwa kwempahla njengoMark Thompson, Sourcing ethembekile, ikhwalithi ephezuluama-electrodes we-graphitekubaluleke kakhulu. Njengoba kunikezwe amaphoyinti obuhlungu angaba khona wekhwalithi engahambisani, ukubambezeleka kokuthumela, kanye nezinkinga zesitifiketi, indlela yamasu ekukhethweni kwabahlinzeki nokuqinisekiswa kubalulekile. Nazi izinyathelo ezibalulekile abathengi abangathatha:

- Umhlinzeki Omhlinzeki Ngokuphelele:Musa ukuthembela nje ngentengo. Ucwaningo olungaba khona. Funa amafektri asungulwe ngerekhodi elifakazelwe, njengesikhungo sethu eChina enemigqa engu-7 yokukhiqiza. Bheka isipiliyoni sabo, izimakethe zokuthekelisa eziphambili (isipiliyoni nge-USA, Europe, njll., Kubonisa ukujwayelana namazinga aphesheya), namandla okukhiqiza.

- Cela isitifiketi nemibiko yokuhlola:Cela imininingwane enemininingwane enemininingwane, imibiko yokuhlaziywa kwezinto ezibonakalayo, kanye nezitifiketi ezifanele (e.g., ISO 9001 yokuphathwa kwekhwalithi). Ngenkathi ukuphaphama ngokumelene nenkohliso kuyadingeka, abahlinzeki abasemthethweni bahlinzeka ngemibhalo ephelele yaboI-electrodeimikhiqizo. Buza noma yikuphi ukungafani.

- Qondisisa amamaki (RP, HP, UHP):Qinisekisa ukuthi umphakeli uhlukanisa ngokusobala phakathiIzinhlobo ze-graphite electrodesfuthi unganikeza ibanga elithile (HpnomaUhp) Kudingeka okwakhoUgesi we-arc kagesi. Xoxa ngeimpahla eluhlazaisisekelo (e.g., ingxenye yeinaliti cokeingomaneI-UHP Graphite).

- Buza ngokulawulwa kwekhwalithi:Buza ngezinqubo zabo ze-QC kulo lonke elakhiwa - kusukaimpahla eluhlazaukuhlolwa kuukusakazaukulawula nokokugcinaI-electrodeimishini nokuhlola. Baqinisekisa kanjani ukuvumelana?

- Xoxa ngezinto eziphilayo nezikhathi zokuhola:Khulukisa ngokusobala amashejuli akho adingekayo. Abahlinzeki abanokwethenjelwa baqonda umthelela wokubambezeleka futhi kufanele bahlinzeke ngezikhathi ezingokoqobo zokuhola futhi babe namalungiselelo wokuphambuka wokulungisa. Ukulungisa izingqinamba ezingaba khona zokuthumela ezingaba khona.

- Funa izinkomba noma izifundo zamacala:Abakhiqizi abadumile bavame ukuba nezinsolo noma izifundo zamacala ezivela kumakhasimende anelisekile, kungenzeka ngisho esifundeni sakho (e-USA, eNyakatho Melika, eYurophu).

- Cabanga ngocwaningo lwefektri noma ukuhlolwa kwalowo nalowo:Ngokuthenga okukhulu noma ubudlelwano bomhlinzeki omusha, ukuhlela ukucwaningwa kwamabhuku noma ukuhlolwa kwangaphambi kokuthumela kunganikeza isiqinisekiso esengeziwe mayelana nekhwalithi nezinqubo.

- Yakha ubudlelwano:Ukuxhumana okuvulekile kubalulekile. Sebenza nabaphakeli abaphendulayo, abavumayo, futhi abazimisele ukuqonda izidingo zakho ezithile maqondanaAma-electrodes e-EAFUkusebenza. Njengoba u-Allen, ngibeka phambili ukuxhumana okucacile namakhasimende afana noMark.

Ngokuthatha lezi zinyathelo, abathengi bangathuthukisa kakhulu amathuba abo wekhwalithi ephezuluAma-electrodes asetshenziswa e-EAFUkusebenza, ukunciphisa ubungozi kanye nokuqinisekisa ukusebenza kwenkonzo yokwethenjelwa. Imikhiqizo efana neyethuInduku ye-graphiti evutha ama-electrodesna-Amabhulokhi we-graphite anamandla aphezulukhombisa ukuzibophezela kwethu ezintweni zekhwalithi.

Uma ubheka phambili: Indima evelayo ye-lectrodes ye-graphite ekukhiqizweni kwensimbi esimeme

Le khasiUgesi we-arc kagesiIndlela, uthembele kakhulu kuama-electrodes we-graphite, isivele iyitshe legumbi lokukhiqizwa kwensimbi eluhlaza ngenxa yekhono layo lokuphindaisiketa. Njengoba i-global push yokusimama iyaqina,Indima ye-graphite electrodesna-Eaf Stebilemakingisethwe ukuthi ibaluleke ngokwengeziwe. Intuthuko yesikhathi esizayo cishe izogxila ekuthuthukiseni kahle futhi yehlisa umthelela wezemvelo wale nqubo. Lokhu kufaka phakathi ucwaningo oluqhubekayoI-electrodeizinto zokwakha kanye nokugqoka ukunciphisaoxidationkanye namanani aphansi aphansi, okuthinta ngokuqondile izindleko zokusebenza nokusetshenziswa kwezinsiza.

Ngaphezu kwalokho, izinto ezintsha kuUqhingiubuchwepheshe uqobo, njengenqubo ethuthukisiwe yokulawula, izinhlelo ezithuthukisiwe zokubuyiselwa kwamandla, nokusetshenziswa okungavuselelwa okuvuselelekayoamandla kagesiimithombo yokufaka amandlaucezu lwesiyingi, kuzohambisana nentuthuko kuI-electrodeubuchwepheshe. Idrayivu ebheke phezuluukuqina kwamanjeUkusebenza ukukhulisa umkhiqizo kuzoqhubeka nokufuna ukuthuthuka kuI-UHP Graphite I-electrodeikhwalithi, ikakhulukazi maqondanaimpambaukumelana nokuzethusa futhiAmandla Omshini. Njengoba siqhubekela phambili, ukuvumelanisa phakathi komklamo osebenzayo wesithando somlilo nokusebenza okuphezuluama-electrodes we-graphitekuzoba kubalulekile ekwenzeni ukukhiqizwa kwensimbi kube namandla, kunciphise ukuthembela kuImfashini yendabuko yendabuko, futhi kufaka umnotho oyindilinga ngokuphinda usebenzise kabushaisikena sensimbi. AbathobekileyoI-Graphite Electrodeizohlala iyingxenye ebaluleke kakhulu ngokuzayoinsimbi enanamuhla.

I-Key Takeaways: Ama-elektrode we-graphite ku-EAF Stebilemaking

- Ingxenye ebalulekile: Ama-electrodes we-graphitezibalulekileUgesi we-arc kagesi(EAF) ukusebenza, ukuqhubaElectric yamanjekudingekadala i-arc kagesina-ncibilikisa klabuthainsimbi.

- Izakhiwo ezihlukile:I-Graphite ikhethelwe phezuluukuqina kukagesi, ehlukileUkumelana nokushisakwa-ukumelana namazinga okushisa aphezulu, futhiamandla aphezulu wemishiniedingekayo endaweni enokhahlo.

- Basebenza kanjani: I-electrodesphatha phezuluUkudlula kwamanjeukukhiqiza iucezu lwesiyingiphakathi kweI-electrodeIthiphu kanyeklabutha, ukukhiqizaukushisa okukhulungokuncibilika.

- Izinhlobo zibalulekile: I-electrodeswoza amamaki -Amandla ejwayelekile (RP), Amandla aphezulu (HP), futhiAmandla we-Ultra-High (UHP)- ngokusekelwe kuAma-Raw material (UPetroleum Coke, inaliti coke) Futhiukuqina kwamanjeamandla. Ukuqhathanisa i-I-electrodeThayipha esithandweni somlilo kubalulekile.

- Izindleko zekhwalithi Izindleko:Ikhwalithi ephezuluama-electrodes we-graphiteKuholele ekusetshenzisweni okuphansi, ukusebenza kahle kwamandla, ukukhiqiza okuphezulu, futhi kuncishiswe izingozi zokusebenza uma kuqhathaniswa nezinketho ezisezingeni eliphansi.

- Ukuhlanza amasu:Abathengi kufanele basebenzise kahle abahlinzeki, qinisekisa izitifiketi, baqonde amamaki e-electrode, babuze nge-QC, bese bexoxa ngezinto zokufunda ukuze baqiniseke ukuthi banosizo oluthembekile.

- I-EAF Greener: Eaf Stebilemaking, inikezwe amandla yiama-electrodes we-graphite, idlala indima ebalulekile ekusebenzeni kabushaisiketafuthi inikeza enye indlela eqhubekayoIzindlela Zendabuko.

- Ukugxila Ekusasa:Ukuthuthukiswa okuqhubekayo kuhlose ukuthuthukaI-electrodeUkusebenza kahle (ukusetshenziswa okuphansi, ukusebenza okuphezulu) futhi kuhlanganiswe nentuthuko kubuchwepheshe obusebenzayo be-EAF Technology.

Isikhathi sePosi: 05-06-2025