use of graphite electrodes in steel making

Graphite electrodes are essential consumables in the production of steel through the electric arc furnace (EAF) method. These electrodes conduct electricity and generate the intense heat required to melt scrap steel or direct reduced iron (DRI), playing a critical role in modern, energy-efficient steel production.

How Graphite Electrodes Are Used in Steelmaking

-

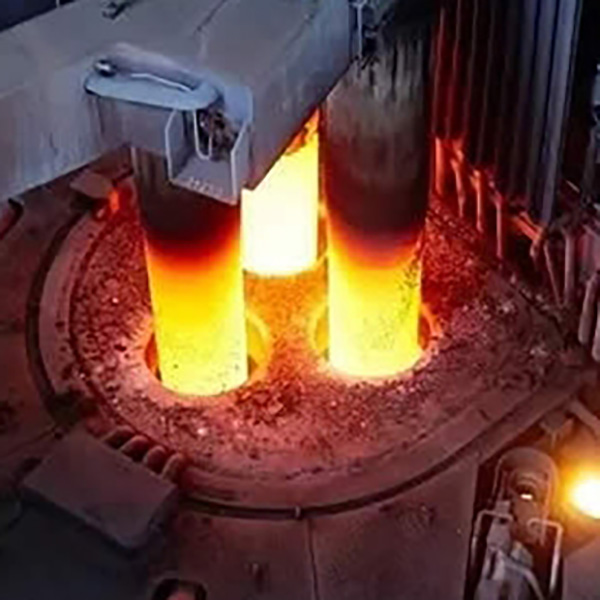

Electric Arc Furnace (EAF) Operation:

-

In an EAF, three large graphite electrodes are inserted vertically into the furnace.

-

An electric current passes through the electrodes, generating arcs between the tips and the metal charge.

-

These arcs can reach temperatures of 3,000°C or higher, which is sufficient to melt scrap metal and produce liquid steel.

-

-

Conductive Role:

-

Graphite electrodes serve as conductors of electricity, allowing high-voltage current to flow into the furnace with minimal resistance and energy loss.

-

-

Heat Generation:

-

The intense heat from the electric arc between electrodes and scrap melts the metal quickly and efficiently.

-

The process is faster and cleaner than traditional blast furnace methods.

-

-

Structural Function:

-

Electrodes must be strong enough to withstand thermal shock, mechanical stress, and chemical exposure in the furnace environment.

-

Why Graphite is Used:

-

High Electrical Conductivity: Transfers large amounts of electricity efficiently.

-

Thermal Resistance: Withstands extreme furnace temperatures without melting.

-

Mechanical Strength: Endures mechanical stresses during the steelmaking process.

-

Low Impurity Content: Reduces contamination in the steel product.

-

Oxidation Resistance: Coatings or large sizes reduce loss in oxygen-rich environments.

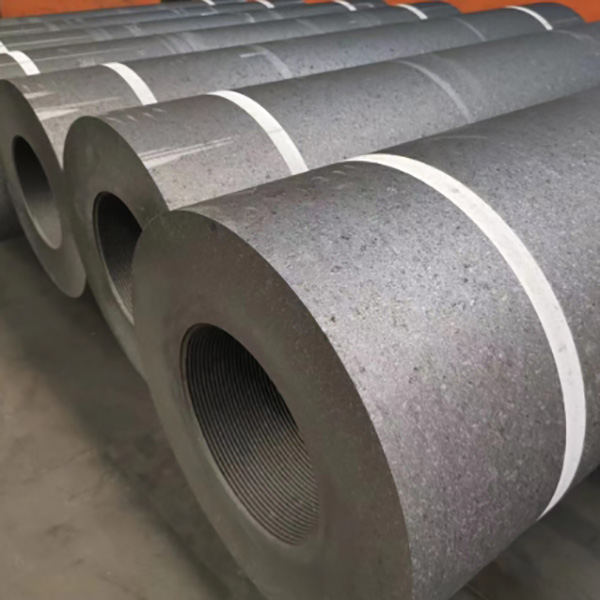

Types of Graphite Electrodes Used in Steelmaking:

-

RP (Regular Power): For low-current operations

-

HP (High Power): Suitable for medium-capacity furnaces

-

UHP (Ultra High Power): Used in high-efficiency, large-scale steel mills

Lifecycle and Replacement:

-

Electrodes gradually wear down during use due to oxidation, consumption, and mechanical breakage.

-

The tips are replaced by screwing on new electrode sections using nipples.

Benefits in Modern Steelmaking:

-

Energy-efficient production

-

Lower carbon footprint compared to blast furnace methods

-

Flexible operations using scrap and alternative iron sources

-

Cost-effective for small and medium-sized steel plants