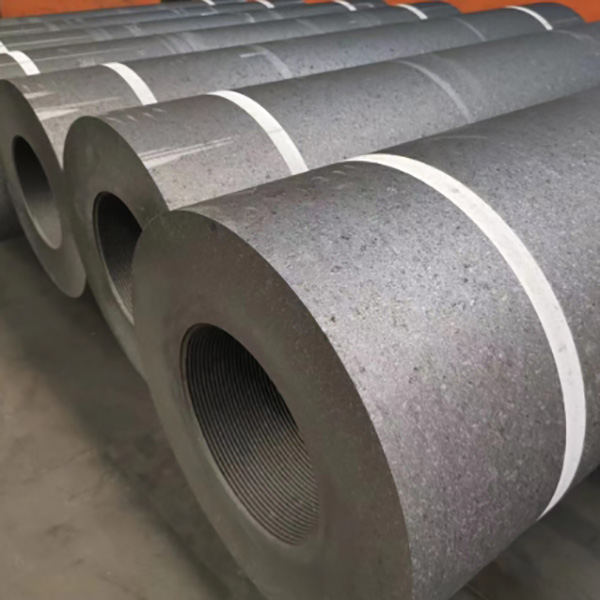

Ultra High Power Graphite Electrode (UHP)

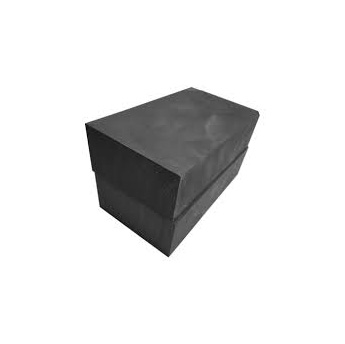

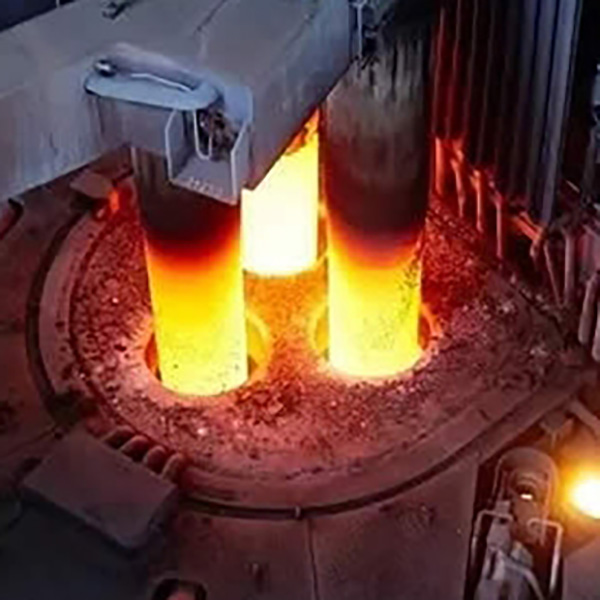

Ultra High Power (UHP) Graphite Electrodes are premium-grade carbon electrodes designed specifically for use in electric arc furnaces (EAFs) and ladle furnaces (LFs) for steelmaking and ferroalloy production. Manufactured using needle coke and produced through a high-pressure molding, multiple baking, and full graphitization process at temperatures up to 3000°C, UHP electrodes offer the highest electrical conductivity, thermal shock resistance, and mechanical strength available in the industry.

These electrodes are engineered to handle extremely high current densities and are essential for high-efficiency steel production with minimal electrode consumption.

Key Features:

-

High Current Capacity: Capable of carrying extremely high amperage for rapid melting and arc performance

-

Exceptional Electrical Conductivity: Low resistivity ensures efficient power usage and faster melt times

-

Superior Thermal Shock Resistance: Performs reliably in harsh EAF/LF environments with sudden temperature changes

-

High Mechanical Strength: Withstands mechanical stress and oxidation during high-load cycles

-

Low Consumption Rate: Reduced electrode wear helps minimize downtime and production costs

Typical Applications:

-

Electric Arc Furnaces (EAFs): For steel recycling and alloy production

-

Ladle Furnaces (LFs): Secondary metallurgy operations

-

Submerged Arc Furnaces (SAFs): In ferroalloy production

-

Refining of Stainless Steel and Special Alloys

Technical Specifications (Typical):

| Property | UHP Grade Value |

|---|---|

| Bulk Density | ≥ 1.68 g/cm³ |

| Electrical Resistivity | ≤ 5.5 µΩ·m |

| Flexural Strength | ≥ 10.0 MPa |

| Elastic Modulus | ≤ 13 GPa |

| Thermal Conductivity | ≥ 145 W/m·K |

| Ash Content | ≤ 0.3% |

| Apparent Porosity | ≤ 20% |

| Current Carrying Capacity | 20,000 – 45,000 A (varies by size) |

Available Sizes:

-

Diameter Range: 250 mm (10”) to 700 mm (28”)

-

Length: 1600 mm to 2700 mm

-

Nipple Types: 3TPI, 4TPI, or customized threading systems

-

Packaging: Steel-strapped wooden crates with anti-impact protection

Advantages Over HP and RP Electrodes:

-

Higher current carrying capacity

-

Lower electrode consumption per ton of steel

-

Superior performance in high-load melting cycles

-

Better energy efficiency and furnace productivity

Conclusion:

UHP graphite electrodes are the top-tier choice for modern, high-efficiency electric arc furnace operations, offering exceptional conductivity, strength, and reliability. Ideal for steelmakers seeking lower energy costs, faster production, and reduced electrode consumption.