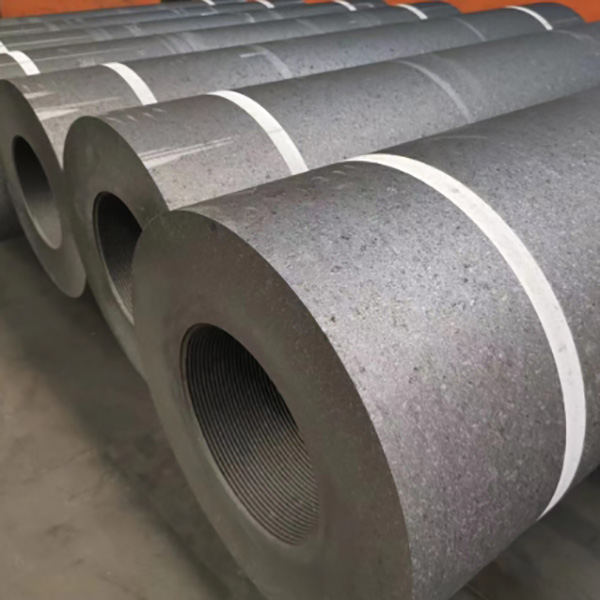

uhp graphite electrode price

UHP (Ultra High Power) graphite electrodes are premium-grade electrodes designed for use in electric arc furnaces (EAF) and ladle furnaces (LF) operating at extremely high current densities. Manufactured using needle coke and processed through multiple stages of baking, graphitization, and machining, UHP electrodes offer superior electrical conductivity, mechanical strength, and thermal shock resistance.

These electrodes are essential in modern steelmaking, especially for high-efficiency steel mills and continuous melting operations.

Key Features:

-

High Current Carrying Capacity: Ideal for intensive smelting operations

-

Low Electrical Resistivity: Typically 4.5–5.8 µΩ·m

-

Excellent Thermal Conductivity: Withstands rapid temperature changes

-

High Mechanical Strength: Resists breakage under arc and load stress

-

Low Ash Content: Minimizes contamination in steel production

Applications:

-

Electric Arc Furnace (EAF) steel production

-

Ladle furnace refining

-

Ferroalloy and non-ferrous metal smelting

-

High-capacity foundry operations