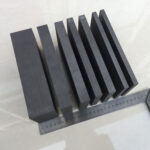

Solid Block of Graphite

A solid block of graphite is a dense, monolithic piece of synthetic graphite engineered for high-temperature, high-conductivity, and chemically resistant applications. Manufactured from high-purity petroleum coke and coal tar pitch, then baked and graphitized at temperatures up to 3000°C, these blocks exhibit excellent thermal conductivity, machinability, and structural integrity.

They are widely used across metallurgy, electronics, glass manufacturing, foundries, and energy systems, where durability and heat resistance are critical.

Key Features:

-

High Temperature Resistance: Operates stably up to 3000°C in inert or vacuum environments

-

Excellent Thermal & Electrical Conductivity: Efficient for heat dissipation or current transfer

-

Chemically Inert: Withstands most acids, alkalis, and corrosive gases under high heat

-

Machinable: Can be easily shaped or milled into components, crucibles, dies, or electrodes

-

Non-Warping & Stable: Retains shape under extreme thermal cycling and mechanical stress

Typical Applications:

-

Foundry and Casting: Mold making, die inserts, and chill blocks

-

EDM (Electrical Discharge Machining): Electrode blocks for mold and precision part creation

-

Furnace Parts: Insulation, shelves, and support structures for high-temperature ovens

-

Battery and Fuel Cell Systems: Current collectors and bipolar plates

-

Glass and Ceramic Manufacturing: Support trays, stoppers, and forming molds

Technical Specifications (Typical):

| Property | Value Range |

|---|---|

| Density | 1.75 – 1.90 g/cm³ |

| Carbon Content | ≥ 98–99.9% |

| Electrical Resistivity | 8 – 15 µΩ·m |

| Compressive Strength | 60 – 120 MPa |

| Flexural Strength | 30 – 60 MPa |

| Ash Content | ≤ 0.1% |

| Thermal Conductivity | 100 – 170 W/m·K |

| Grain Size | Fine (< 0.8 mm) or ultra-fine |

Available Sizes:

-

Standard Dimensions:

-

300×300×100 mm

-

400×400×200 mm

-

600×600×300 mm

-

-

Custom Sizes: Available based on user requirements

-

Pre-Machined Options: CNC services for specialty components

Handling & Storage:

-

Store in a dry, clean location

-

Avoid impact or heavy loads to prevent chipping

-

Handle with care during machining to maintain surface integrity