Magetsi arc echoto (EAF) tekinoroji inomira sekona yedombo rezvazvinoSteelmaking, Kupa kuchinjika uye kushanda zvakanaka, kunyanya mukudzokororwasvetuka simbi. Pamwoyo kwazvo wechiitiko ichi chine simba ndizvoGraphite Electrodes. Aya haasi matanda akareruka; Ivo vane hunyanzvi kwazvo vanonzvera zvinokatyamadza kuti vaendese zvakakurasimba remagetsiinodiwaMelt Scapuyegadzira simbi. Kunzwisisa basa, mhando, zvinhu zvemhando yepamusoro, uye kubata kwakakodzera kweizviElectrodesyakakosha kune cheroMagetsi arc chotoOperator, maneja akawanikwa, kana nyanzvi yekugadzira saMark Thompson achimanikidza kuita kwakakwana uye mutengo-kushanda. Ichi chinyorwa chinopera zvakadzika munyika yearc chevelele electrodes, achitsanangura chikonzerographitendicho chinhu chesarudzo, seiarcInoshanda mashiripiti ayo mukatichoto, Chii chinotsanangura hunhuElectrode, uye kusanganisa sei nemugadziri wechigadziri senge, ne7 yekugadzira mitsara pano kuChina, inogona kuchengetedza mashandiro ako. Isu tichaongorora zvese kubva kuZvishandiso zvakagadzirwakune yekupedzisiraSteelmaking Process, Kuverengera kuti unonzwisisika kuchida kuita sarudzo dzine ruzivo.

Chii chaizvo chinonzi magetsi arc (eaf) uye inosimbira sei?

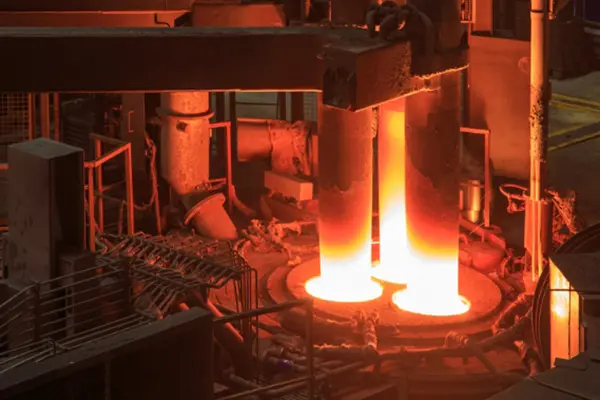

AnMagetsi arc choto, kazhinji kazhinji senge eaf, rudzi rwechotoizvohetskubhadharisa zvinhu kunyanya nenzira yeElectric arc. Funga nezvazvo segurukisi hombe, asi panzvimbo yekupisa mvura, iyoMeltsmatani esvetuka simbiUye mamwe masimbi anoshandiswa anoshandisa tembiricha yakakwirira inogadzirwa nemagetsi. Izvizvirotovaridzi vebasa muSimbi Indasitiri, inonyanya kufarirwa nekugona kwavo kudzoreredzaScrap Simbi, kugadziraSteelmaking Processzvinoshanda zvakawandisa zvichienzaniswa netsikakuputika machiraiyo yakanyanya kuvimba nedare ore. Iyo yekutanga chimiro inosanganisira mudziyo wekufemedza (chotoShell), denga rine zviteshi zveElectrodes, uye kubaya spout kudurura kunzeyakanyungudutswa simbi.

Maitiro acho anotanga nekuisa iyochotonasvetuka simbi(iyo yekutangaFeedstockuye dzimwe nguva zvimweZvishandiso zvakagadzirwaKufanana nesimbi yakadzama (dr) kana pig iron. Akamboremerwa, denga rakamisikidzwa munzvimbo, uyeGraphite Electrodesvanodzikiswa vakananga kuScrap. Iyo yakanyanya magetsi akanyanyaZvazvino Kupfuura kuburikidza neElectrodeinogadzira simbaMagetsi arcspakati peElectrode Matipiuye simbi yekuita. Izviarcunogadzirakupisa kukuru, inosvika tembiricha inogona kupfuura zviuru zvitatuDhigirii celsius(Kusvika5000 madhigiriiFahrenheit muArc pachayo), iyo nekukurumidzainonyungudutsa simbi simbi. Izvo zvesechotokazhinji anogara pane aTilting Puratifomukubvumira kudurura kweyakanyungudutswa simbiKamwe zvaunodatembiricha uye chemistryzvinowanikwa.Eafszviri zviviri, zvinokwanisa kuburitsa huwandu hwakawanda hweSimbi mamakisi.

Kunyatsobudirira uye kumhanya kweMagetsi arc chotondazviita tekinoroji isimba mukatiSteelmakingPasi rese. KusiyanaInduction inofurwaizvo zvinoshandiswaEddy Mafungukutikupisasimbi, iyoEafinoshandisa yakanangakupisayemagetsi arc kuti inyungudukemhosva. Ichi chiitiko chakananga chasimba remagetsiinobvumira kukurumidza kunyungudika. The thechotopachayo inofanira kusimba, ine ganda kazhinjiyakarongedzwa neyefractoryzvinhu zvakaitaRefractory zvidhinhakutitsungiriramamiriro akanyanya. ZvazvinoEafsSuperedza masisitimu ekudzora epamberi,mvura-yakatonhoreramapaneru emadziro uye denga, uye mashandiro emuchina ekubataElectrodesuye kubatanyungudika.

Magetsi emagetsi emagetsi anogadzira sei kupisa kwakasimba kunodiwa mune choto chemafuta?

Mashiripiti eMagetsi arc chotoari muElectric arcpachako, uyeGraphite ElectrodesKo iwo Anobata Anoita Kuti zviitike. Kazhinji,Matatu Electrodesanoshandiswa mune AC (kuchinjanisa zvazvino)choto, yakarongedzwa nenzira yakatsetseka. Izvicylindricalmakoramu agraphiteita sematare emasimba emagetsi epamusoro, yakabatana kuburikidzatambo dzakakura dzemvura dzakatonhorera. Kana iyoelectrodes yakaderedzwapedyo neiyo simbi yekuchaja (svetuka simbi) Mukatichoto, vhesi yakakwira inoiswa. Iyi voltage iionises iyo mhepo (kana magasi) musango pakati peElectrodetip uyeScrap, kugadzira nzira yekuzvibata.

Kamwe nzira iyi yasimbiswa, yakakuramagetsi aripo(makumi ezviuru zveAmperes) inoyerera kuburikidza neElectrodesuye kusvetukira mhiri kwegomba, kuumba kusimbiswaElectric arc. IzviarcChaizvoizvo inonyanya kuenderera, yakakwira tembiricha plasma discharge. Inoshandurasimba remagetsikuva Thermalsimbanekubudirira kunoshamisa, kusunungura hurukupisazvakananga kuScrap Simbi. Ndozvakaratidzwa izvi,kupisa kukurukubva kuarc(kanaarcs, mune matatu-Electrodesetup) iyo inorema kusimudza, nekukurumidza ichinyungudutsa iyoScrapuye kugadzira ayakanyungudutswa dziva. The theElectrodesvanodzorwa chaizvo kuti varambe vakakwanaarckureba uye kugadzikana mumamiriro ese ekunyungudika.

Simba rakapihwa kuburikidza neElectrodesakakura kwazvo. Funga nezve simba rinodiwa kutinyungudikamatani eSolidsimbimukati meawa - ndiyo chiyero chatiri kushanda. The theElectrodesivo pachavo vanopedzwa panguva iyi yekuita nekuda kweoxidationpamazano avo uye nekutanga mukunyanyisakupisayearc, asi yavo yekutanga basa ndeyekuitisa zvinodikanwa zvazvino uye zvichiriritiraarcinodikanwakupisa uye nyungudikaChirahwe zvinobudirira. Kugadzikana uye kusimba kwearczvakananga kukanganisachotoKubereka uyesimba rekushandisa, zvichiratidza basa rakaoma reElectrodesystem.

Nei graphite graphite iyo isina kuora zvinhu yeARC Fira yeARC Electrodes?

Mamiriro ari mukati meMagetsi arc chotovari kuda kwazvo. Tembiricha dzinodziya, magetsi magetsi akakura, uye kuvhunduka kwekunze kwakasimba. Saka, neigraphite? Wadii kupperevera kana tungsten? Mhinduro iri mukatigraphite'S yakasarudzika musanganiswa wezvivakwa, uchiita kuti ive yakakodzera sevhisi seElectrodemunzvimbo idzi dzakanyanyisa. Semugadziri, isu tinovimba zvakanyanya nehunhu uhu hwani.

Chekutanga,graphiteine yakakwirira yakakwirirainobatauye kupokana kwakanaka kune yekunyanyisa kuvhunduka. Izvi zvinoreva kuti zvinogonatsungiriraIko kukurumidza tembiricha shanduko ine ruzivo kana iyoarcanorova uye panguva yekunyungudika pasina kupaza nyore kana kukundikana.Graphite inogona kumiratembiricha dziri kure kwazvo nekunyungudika nzvimbo yekunyungudutsasimbi. Wechipiri,graphiteinochengeta yayoSimba reMuchinazvinoshamisa chaizvoyakakwira-tembirichamazinga, kusiyana nesimbi zhinji dzinoshungurudza zvakanyanya. Uku kuperera kwakasimba kunokosha kune iyo yakarebaElectrodemakoramu anoshandiswa mune yakakurazviroto.

Chechitatu, uye chinonyanya kuitaElectrode, graphiteanekudzikisira kwemagetsi kurwisa(kana magetsi akakwirira magetsi). Izvi zvinobvumidza kutakura mafungu makuru anodikanwa kunearcpasina kunyanyisa kupisa kwemukati (kupisakurasikirwa) kana voltage kudonha. Itskupokana kwakadererainovimbisa inoshanda simba rekuendesa kune iyonyungudika. Chechina,graphiteine nzvimbo yakanyanya kuwanda kwazvo NepoElectrodekushandiswa kuburikidzaoxidationuye kugunun'una kunoitika,graphiteKukwanisa kutsungirira mamiriro aya kwakakwirira kwazvo kune zvimwe zvinhu zvinowanikwa. Maitiro ekugadzira, anosanganisiragrafitifizationpakukwirira kwakanyanya, inoenderana necarbon dhizaini kuti ivirise izvithermal uye magetsizvivakwa. Iko kusanganisa uku kwekushambadzira kwekuparadza, simba rakanyanya-tembiricha, uye magetsi maitiro anoitagraphitezvinhu zvisingabvumirwearc chevelele electrodes.

Ndeapi mamakisi akasiyana eGraphite Electrode aripo kuti arove steelmaking? (UHP, HP, RP yakatsanangurwa)

Kwete zvesemagetsi arc machirazvakasikwa zvakaenzana, uye kweteGraphite ElectrodesIvo vanoshandisa. Zvinodiwa zvakaiswa paneElectrodekusiyanisa zvakanyanya zvichienderana nechotoMwaka masaji, maitiro anoshanda, uye rudzi rwesimbikugadzirwa. Kusangana nezvido zvakasiyana siyana,Graphite Electrodes anoshandiswamumakiredhi akasiyana, kunyanya kuratidzwa nekwavo-kutakura basa uye zvivakwa zvemuviri. Sefekitori sedzedu seyedu, isu tinoburitsa huwandu hweizvi kuti tipe kune zvinokonzeresa vatengi zvinodiwa.

Mamakisi makuru earc chevelele electrodes inosanganisira:

- Pfuma yenguva dzose (RP):IzviElectrodeszvakagadzirirwa kuderera-poweredmagetsi arc machira, kazhinji izvo zvinoshandiswa mumavheni kana kuti zvisingadiweSteelmakingmashandiro. Ivo vanoshandisa yakajairika mhando petroleumCokeuye iva nemwero mwero density kugona.

- Simba rakakwirira (HP):HpElectrodesGovera zviri nani kuita pane rp mamakisi. Ivo vanoitwa vachishandisa yepamusoro mhando petroleumCokeuye inogona kubata yakakwira zvazvino densities. Izvi zvakakodzeramagetsi arc machirakubatanidzwa mune standardSteelmakinguye mashandiro ekunatsa. Iwe unogona kuongorora sarudzo senge yeduYakakwira-simba graphite electrodeyekuita yakavimbika kuita mune izvi zvekushandisa.

- Ultra-Yakakwira Simba (UHP):Izvi ndizvo zviri kumusoro-tierElectrodes, Injiniya yekunyanya kudiwaMagetsi arc chotozvikumbiro.UHP Electrodesanogadzirwa uchishandisa premium tsonoCoke, iyo inopa chimiro chepamusoro, kuparadzaniswa kwemagetsi, kukwirira kwakanyanya, uye kuramba kuri nani kune zvekupisa zvakanyanya uyeoxidation. Ivo vanogona kutsungirira zvakakwirira zvakakwirira zvazvino dentys, vachiita kuti vakwanise kuve vakakura, vakakwira-chigadzirwaEafskujairagadzira simbinekukurumidza uye zvinobudirira. EduUltra-Yakakwira Simba Graphite Electrodeyakagadzirirwa zvakananga idzi dzakaoma nharaunda. Zvekukurazviroto, nyanzviYakawedzera yakakura graphite electrodesaizi zvakare inowanikwa zvakare.

Sarudzo yeElectrodegiredhi zvakananga zvinokanganisachotokushanda zvakanaka,ElectrodeMari yekudhinda, uye yakazara mari yekushandisa. Uchishandisa giredhi rakadereraElectrodeMune yakakwirira-simbachotoinotungamira kukurumidza kunwa uye kugona kwekutsiura, uchishandisa aUHP ElectrodeMune yakaderera-simbachotoinogona kunge isingaiti inodhura. Kufananidza iyoElectrodegiredhi kuna iyochotoZvinodiwa Kiyi yeKufungaEAF Stbeelmakaking.

Iwe unogona kutsanangura rwendo: Ndeipi nzira yepamusoro-mhando yemagetsi emagetsi emagetsi akagadzirwa?

Kugadzira aGraphite Electrodekugona kuita nekuita zvakazara muMagetsi arc chotois a yakaoma, yakawanda-nhanho maitiro ayo anoda kunyatsojeka uye nekuchenjerera kudzora pamusoroZvishandiso zvakagadzirwauye kugadzirisa paramita. Sevadzivisi, tinotarisira rwendo rwuno rwiyo. Inotanga nekusarudza iyo chaiyo carbonaceousZvishandiso zvakagadzirwa, kunyanya yakakwira-mhando petroleumCoke(kunyanya tsonoCokeforUHP Electrodes) uye marasha tar pitch seye binder.

Maitiro acho kazhinji anosanganisira aya makuru matanho:

- Kusanganisa:Iyo yakagadziridzwaCokezvidimbu zvakanyatsorongeka uye zvakasanganiswa zvine mongororo yemarasha tarch. Iyo mienzaniso uye kusanganisa mhando ndeyekutsoropodza kwekupedzisiraElectrodezvivakwa.

- Kugadzira (kuumbwa kana kuumbwa):Iyo yakadzika paste-kunge musanganiswa unobva yaumbwa mune yaunodacylindricalchimiro, kazhinji kuburikidza nekuwedzera kweiyo standard saizi kana kuumbwa kweakakura kwazvoElectrodeskana maumbirwo akakosha. Izvi zvinoumba "girini"Electrode.

- Kubheka:GiriniElectrodesvanopisa zvishoma nezvishoma mukubheka kukuruzvirotoAnopfuura mavhiki akati wandei ekupisa kwakakomberedza 800-1000Dhigirii celsius. Iyi process inobatanidza iyo gomba binder, inogadzira iyo yakasimba kabhoni chimiro uye kutyaira kubva kuhutori zvinhu. Kudzora kwekudziya kwekushisa kwakakosha kudzivirira kupaza.

- Kusimbisa (kusarudza asi zvakajairika kune HP / UHP):Kuwedzera density uye simba, yakabikwaElectrodeszvinowanzokwirwa nemvura yakadzika pasi pekumanikidzwa uye wobva wabikwa. Izvi zvinozadza pores yemukati.

- Graphifization:Iyi ndiyo inonyanya kutsoropodzwa uye simba-yakanyanya nhanho nhanho. KubikwaElectrodesinocherwa mune yakasarudzikamagetsi magetsi(saCheSonzviroto) kune yakanyanya kupisa tembiricha, kazhinji pakati pe2500 ne3000Dhigirii celsius. Uku kwakanyanyakupisainoshandura iyo Amorphous Carbon dhizaini muCrystallinegraphite. IzvigrafitifizationNhanho ndiyo inopa yakanakisathermal uye magetsiKubata KunodiwaEAF Electrodes.

- Machining:Mushure mekutonhora, iyo grapitizedElectrodesvane hunyanzvi-mashandiro kune chaiwo matanho. Izvi zvinosanganisira kuvacheka kusvika pakureba uye kugadzira zvigadziko zvakamanikidzwa pamagumo ega ega. Zvigadziko izvi zvinotendera munhuElectrodeskubatanidzwa pamwechete uchishandisa mapini ekubatanidza (nipples), zvakare yakagadzirwa negraphite, kugadzira makoramu marefu anosvika muchoto. Kunyatsojeka kweThreadyakakosha kune yakasimba, yakaderera-kuramba majoini.

Muzviitiko izvi, zvine mutsindo zvemhando dzekutonga dzinoitwa, kubva pakuongorora zvinhu zvekunyora kuti zviongorore zvekuongorora kwekupedzisira kweiyo michinaElectrode. Rwendo rwekubva pakunyatsosarudzwaZvishandiso zvakagadzirwakune yakanyanya chigadzirwa chigadzirwa chakagadzirirwa kutitsungiriranharaunda yekuranga yeMagetsi arc choto.

Ndeapi maitirwo emhando ekutarisa anoona kuti electrode yekuita panguva yechiripo ichinyungudika?

Kune steelmaker kunge Mako Thompson, zvinoenderanaElectrodekuita kuri kuteedzera. Kukundikana kusingafadzwe kana kuti kwakakwirira kunwa kunogona kukanganisa marongero ekugadzira uye kuwedzera zvakanyanya mutengo. Naizvozvo, simbisai kunaka kweGraphite Electrodeshaisi kungoita bhokisi rekutarisa; Izvo zvakakosha kuvimbikaMagetsi arc chotokuvhiya. Panguva yedu yefekitori, kutonga kwemhando yepamusoro kwakabatanidzwa mune imwe neimwe nhanho, kubva pakutakura zvinhu zvekutakura kwekupedzisira kutumira.

ZVINOKOSHA ZVINOGONESA ZVINOGONESA TINOGONA KUTI TINOGONESA ZVINOGONESA:

- Raw zvinyorwa zvemhando:Kuratidza zvivakwa zvekupinda peturuCokeuye pitch binder. TsonoCokemhando inonyanya kuomaUHP Electrodes.

- Kukura Kwekudzvinyirira:KuverengeraElectrodeDivhenekeri, kureba, uye kuchenjera, iko kutsanangurwa kweiyo makagadziko emakona uye kubatanidza nipples (Threadkururamisa) kusangana nemishonga yakaoma. Majoini akakodzera anokonzeresa anowedzera kurwisa kwemagetsi uye anokundikana kukundikana.

- Zvivakwa zvemuviri:Kuedza samples kubva kune yega yega yekugadzira batch yezvinhu zvakadzora se:

- Density inooneka:Yakakwira density inowanzo kuratidza kunaka kwakanaka uye kuderera kwekushandisa.

- Basa remagetsi:Kudzikisira kwakadzikira kunoreva zviri nani kuitisa uye kushoma kurasikirwa mukati meElectrode. Izvi zvakakosha kutiKubudirira kwehunyanzvi.

- Spines Simba & Modulus yeElasticity:Izvi zvinoratidzaElectrodeSSimba reMuchinauye kuramba kumauto ekukweretesa panguva yekubata uye kushanda mukatichoto.

- Coefficient yeFormal Explansion (CTE):Cte yakaderera inobatsira iyoElectrode Indiathermal kuvhunduka.

- ASH Zvemukati:Yakaderera ASH zvemukati zvinodikanwa kuderedza kusvibiswa kwakaunzwa mukatiSimbi Inely.

- Kutendeka Kwekuvimbika:Uchishandisa nzira dzisiri-dzinoparadza dzekuyedza (kunge ultrasonic kuongororwa) kuti uongorore remukati marara kana zvikanganiso izvo zvinogona kutungamira kukundikana kwekushushikana kanakupisamukati meMagetsi arc choto.

- Certification uye kutengeswa:Kupa mishonga yakazara yebvunzo uye certification (i.e., iso 9001 kutevedzera mashizha) kune yega yega batch, inoona kuwanda kuzere kubva pakugadzira kuburitsa. Kugadzirisa zvinetso nezve chitupa hunyengeri kunoda kuongorora kwehuwandu uye kusimba zvinyorwa kubva kumutengesi.

Aya anotarisa pamwe chete ngaave nechokwadi chekutiElectrodesinopihwa inogona kubata iyo yakataurwa yemagetsi mutoro, ramba iyo hutsinyechotoNzvimbo (kupisa kukuru, inovhunduka, yekumanikidza kushushikana), uye ipa fungidziro yekufungidzira yekunwa mitengo, kubvumirasteelmakerskushanda kwavoEafszvakanaka uye nekuvimbika.

Maguta eMaguta anobatwa sei uye akabatanidzwa muImagetsi arc chvava chiripo?

Kunyangwe iyo yepamusoro yepamusoroGraphite Electrodeinogona kukundikana kana isina kubatwa uye kushandiswa nemazvo. Kupiwa hukuru hwavo, kurema, uye hukama hwenyukumwe tichienzanisa nesimbi, maitiro akakodzera akakosha kudzivirira kukuvadza uye kuve nechokwadi chekushanda nekuchengeteka mukati meSimbi Chigayo. Isu tinogara tichizivisa vatengi vedu pane zvakanakisa maitiro.

Kubata kunosanganisira kuchenjera kusimudzaElectrodesUchishandisa dhizaini rakasarudzwa kana clinks, kudzivirira kukanganisa kunogona kukonzera marara. Chengetedza chinofanira kunge chiri munzvimbo yakachena, yakaoma, yakadzivirirwa kubva mukukuvara kwemuchina. Paunenge uchigadziriraElectrodetsananguro, iwo makagadziko akaomeswa eElectrodeUye nipple inofanira kunyatsocheneswa kuti ibvise chero guruva kana marara, iyo inogona kuwedzera kurwisa magetsi kujoina. Kushandisa iyo torque chaiyo kana ichisimbisa iyo Joint inokonzeresa - pasi-kusimbisa inotungamira mukukwira kwakanyanya uye nekuvhundutsa, nepo kusimbisa kunogona kukuvadza tambo kanaElectrodechimiro. Nyanzvi dzeTorque torque dzinoshandiswa izvi.

Akambosangana mumakoramu,Electrodeszvakaiswa paElectrodemaoko eMagetsi arc choto. Aya maoko, akabatanidzwa kune simba rekuwanikwa kuburikidzatambo dzakakura dzemvura dzakatonhorera, bvumira iyoElectrodeskumutswa, kudzikiswa, uye kudengenyedera parutivichoto. Panguva yekushanda, theElectrodeKutaurisa system otomatiki kunogadzirisa chinzvimbo cheumwe neumweElectrodekuchengetedza yakagadzikanaarcuye kudzora simba rekuisa. The theelectrodes yakaderedzwazvishoma nezvishoma seScrap Meltspasi uye seElectrode Matipidzinodyiwa. Vashandisi vanotarisaElectrodePerformance, kutsvaga zviratidzo zvekunyanyisa kunwa, tip kupatsanura, kana matambudziko ejoin. Kushanda kwekuchenjerera kunobatsira kuwedzeraElectrodeHupenyu uye Chengetedza Zvinoenderanakupisakupinza kunenyungudika.

Ndezvipi zvinhu zvakajairika zvinomuka nema electrode panguva yekunyungudika maitiro uye vangadyiwa sei?

Kunyangwe kusimba,Graphite Electrodesshanda pamuganho wekutsungirira kwezvinhu mukatiMagetsi arc choto. Nyaya dzinoverengeka dzinogona kumuka panguva yekudanyungudikakutenderera, kukanganisa kugona uye mutengo. Kunzwisisa izvi kunobatsira vashandisi uye maneja ekutakura zvakaita saMark anoita sarudzo dziri nani uye matambudziko ekutambudza.

- Kudhirowa Kwakakwirira:Uku ndiko kunetseka kwakanyanya. Kudya kunoitika kuburikidza:

- TIP Sublimation:Kabhoni vaporizing zvakananga kubva kune tip mune yakanyanyisakupisayearc.

- Oxidation:Carbon ichiita neokisijeni muchotomamiriro ekunze padivi pemativi eElectrode. Izvi kazhinji kazhinji chikamu chikuru chekushandisa.

- Kuputsa:Mhepo kutadza kweElectrodecolumn kana kubatana.

- Kuderedza:Uchishandisa iyo chaiyoElectrodegiredhi (i.e.,Uhpyesimba rakakwirira), optimizingchotoKuisa chisimbiso kuderedza mweya unorema (kuderedzaoxidation), kuramba wakabatanidzwa nekubatana kwakasimba, kunoita sangoarcmutemo, uye dzimwe nguva uchishandisa kudzivirirwa kwekudzivirira kanamvura-yakatonhoreraSpray mhete dzinogona kubatsira kushandisa kunwa.

- Kuputsa:Kamwe kamweElectrodekukundikana kunokanganisa uye kunodhura. Zvikonzero zvinosanganisira:

- Thermal kuvhunduka:Kukurumidza tembiricha shanduko, kunyanya panguva yekutanga kana kuti mvura yakavhurwa mvura.

- Mechan Kushushikana:Zvisingaiti zvinhu zvinodonha kubva padenga remba, kunyanyisa kushamisika, kana kupwanya kunoita zvinokanganisaElectrode.

- Musangano usina kunaka wakabatana:Torque isiriyo kana tsvina tsvina inotungamira mukunyanyisa uye kutadza kwakabatana.

- Yemukati kuremara:Kugadzira Kukanganisa (Kunyangwe RIGORIAL QC inoderedza izvi).

- Kuderedza:ChenjeraScrapmanejimendi, musangano wakakodzera wekubatana, pre-upateElectrodesKana zvichidikanwa, wenguva dzosechotokuchengetedza, uye kushandisa yakakwirira-mhandoElectrodesnezvakanakaSimba reMuchinauye kupokana kwekuvhundutsa.

- Tip Kupararira / Kupaza:Inogona kuitika nekuda kwekukurumidza kupisa / kutonhora cycle kana kusapindirana mukatiElectrodechimiro. Yakakwirira-mhando, homo nativeElectrodeshavadi izvi kune izvi.

- Kupokana kwakanyanya kwemagetsi:Kazhinji inokonzerwa neakasununguka kana yakasviba majoini, inotungamira kuwedzeredza, yakawedzerasimba rekushandisa, uye zvinogona kutadza kubatana. Kugara uchichenesa uye kurongeka kwakanaka kwakakosha.

Kugadzirisa nyaya idzi kunosanganisira kusanganiswa kwekushandisa mhando chaiyoGraphite Electrode, kuita zviito zvepamoyo zviri mukati meSimbi Chigayo, uye kuchengetedzaMagetsi arc chotonemazvo. Kunyatso kutaurirana pakati peElectrodemutengesi uyechotoOperator ndiyowo kiyi yekuongorora uye kugadzirisa matambudziko.

Masimbi angangoita seyako anosarudza yakavimbika graphite electrode electrode?

Zvemako Thompson uye mamwe nyanzvi dzekutakura, kusarudza kodzeroGraphite Electrodemutengesi isarudzo yakaoma uye yakakosha inoshanda uye yemari. Kuwana mumwe wako uyo anopa mukana wekusarongeka Pfungwa dzaMako dzinorwadza Izvi ndizvo zvandiri, Allen, anokurudzira kutarisa pamusoro, zvichibva pane zvatinoita semutengesi wenguva refu kumisika kunge USA, Europe, neAustralia:

- Proven inogadzira hunyanzvi:Tarisa mafaera akasimbiswa nemitsara yakazvitsaurira (kunge yedu 7 mitsara) uye nhoroondo yekugadzira iyo chaiyo mamakisi (Uhp, HP, RP) iwe unoda. Inosangana nezvinhu mukuita tsika dzakaomaGraphite ElectrodeKugadzira maitiro. Kushanyira iyo fekitori, kana zvichiita, kana kuenda kuyorma mikurukuratidzwauko vatengesi vanoratidza kugona kwavo kunogona kupa zvakakosha kunzwisisa.

- Robgust mhando manejimendi system:Inosimbirira pane vatengesi vane zita rechokwadi Bvunza mibvunzo yakadzama nezve maitiro avo emhando yekudzora, kubva pakuongorora kwezvinhu zvoumbozha (Cokekuongororwa) kusvika pakupedzisira chigadzirwa kuongororwa (kuramba, simba, density, zviyero). Kumbira muenzaniso wekuyera bvunzo uye unzwisise maitiro avo ekuona batch-to-batch. Usangobvuma chitupa; bvunza nezve maitiro epasi anomiririra. Izvi zvinobatsira kurwisa zvingangoita chitupa hunyengeri.

- Tsigiro yehunyanzvi uye kutaurirana:Mutengesi akanaka anoita semumwe wako, kwete mutengesi chete. Ongorora ruzivo rwavo rwechikwata. Vanogona kupa zano paneElectrodekusarudzwa, kubata, uye kugadzirisa matambudzikochotoNyaya Dzacho? Ko tarisiro yavo yekutengesa inongotaura, inoziva (kupfuura kungotevedzera kutaura), uye nyore kutaura ne (kugadzirisa zvipinganidzo zvemitauro kana zvichishanda)? Kunyatso kutaurirana kwakakosha, kunyanya kana pakagadziriswa nyaya nekukurumidza.

- Logistics uye kuvimbika:Kurukurirana nguva dzinotungamira, kutumira sarudzo, uye nhoroondo yavo yekutumira ye-nguva yekutumira. Kutakura kunonoka kunogona kumisikidzaSteelmakingmashandiro, saka kuvimbika kukosheswa. Nzwisisa nzira dzadzo dzekutakura kudzivirira kukuvara panguva yekufambisa. Bvunza nezve kwavo kwavo kutumira kune yako nyika (USA, Europe, etc.) uye kujaira kwavo nemaitiro etsika.

- Transparcy uye kuvimba:Tsvaga vatengesi vanovhurwa nezve maitiro avo uye vanoda kupa ruzivo rwakadzama. Kuvaka hukama hwakareba hwakareba zvichienderana nekuvimba zvinowanzo kukosha kupfuura kuchengetedza madhora mashoma paneElectrodeneinosarudzwa kana isina kuvimbika sosi. Kurukuranzira dzekubhadharaUpfut uye ona kuti vakachengeteka uye vanoonekera.

- Mitemo yemakwikwi (kukosha, kwete kungoita mutengo):Nepo mutengo uchigara uri chinhu, tarisa pane kukosha kwese. Zvishoma zvakachipaElectrodeizvo zvinopedza nekukurumidza kana kupwanya kazhinji zvichabhadhara zvakanyanya mukufamba kwenguva nekuda kwekurasa kugadzirwa uye nekumwe kunwa tonisimbi. Ongorora mitengo mumamiriro ezvinhu emhando, kuvimbika, uye kutsigirwa.

Kutsvaga vatengesi vobva vatsvage Google kuzivikanwa, asi kuwedzerwa izvi nekuferefetwa kwakadzama, zvinorehwa cheki (kana zvichiita), uye kuita zvakananga, pamwe pakatarisana nekuratidzwa. Vanotendeutsa vanotengesa vanonzwisisa zvinodiwa zveMagetsi arc echoto steelmakinguye ratidza kuzvipira kune kunaka uye mutengi kubudirira.

Chii chichaitika mune ramangwana kune graphite electrodes mune yemazuva ano yemagetsi arc cheni steelmaking?

Ramangwana reGraphite Electrodesinonyadziswa yakabatana neramangwana reMagetsi arc choto (eaf) steelmaking. Uye ramangwana iro rinotaridzika rakajeka, rinotungamirirwa nehutano kiyi dzinoverengeka.EAF Stbeelmakakinginowanzoonekwa seyakawedzerwa nharaunda ine hushamwari pane tsikakuputika chotonzira, kunyanya nekuda kwekugona kwayo kushandisa yakakwira muzana yesvetuka simbi, kuderedza kudiwa kwechibereko chezvinhu zvekubvisa uye kuderedza co2 emissions pane toni yesimbiyakagadzirwa. Semitemo yezvakatipoteredza inonamatira pasi rose uye kusundira kwehupfumi hwehupfumi hunowedzera, chikamu chesimbiyakagadzirwa kuburikidzaEafsinotarisirwa kuenderera mberi nekukura.

Uku kukura kwakananga kushandurudza mukuda kwekutsigirwa kwemhando yepamusoroGraphite Electrodes. Uyezve, maitiro ari akakura, ane simbamagetsi arc machira (Uhp machira) Kuwedzera kubereka uye kushanda zvakanaka. IzviMazuva ano emagetsi arc machirainoda kuwedzera kuwandaElectrodesinokwanisa kubata yakakwira manhamba uye kushushikana, kusundira vagadziri senge isu kuti tirambe tichivandudza muzvishandiso (Senge sindano yepamberiCoke) uye nzira dzekugadzira kuti dzivandudzeElectrodePerformance - zvakananga zvinoregera kudzikira kwemagetsi kupesana, yepamusoro thermar kuvhunduka kupokana, uye kuderedzwaoxidationmitengo.

Kutsvaga kunoenderera mberi munzvimbo dzakaita se:

- Zvipfeko zvemukati:Kukudziridza zviyero zviri nani zvekudzivirira kudzikisira kudharaoxidation, chinhu chikuru mukatiElectrodekushandiswa.

- Yakavandudzwa Yakabatanidzwa Dhizaini:Kuvandudza iyoThreadDhizaini uye nipple zvinyorwa zvakatodzikisira kuramba uye kubatana kwakasimba.

- Zvimwewo matekinoroji:Nepographiteinoramba yakakurumbira, tsananguro inotsvaga imwe vatakuri vemari, kunyange pasina parizvinographite'S yakazara performance profile yeakakuraEafs. Direct yazvino (Dc) zviroto, kazhinji uchishandisa imwe yakakuraGraphite Electrode, imiririrawo chikamu chemusika chine zvakanangaElectrodezvinodiwa.

- Smart Vaya Mashandiro:Kubatanidza sensor tekinoroji uye AI kuti uwedzereElectrodemutemo, masimba masimba, uye kufanotaura zvingangoitika nyaya, nekudaro kuwedzeraElectrodeHupenyu uyechotokushanda.

Sesteelmakersedzagadzira yakakwirira-mhando simbizvakanyatsonzwisisa uye zvakanaka, kudiwa kwekuvimbika, kwakanyanya-kuitaGraphite Electrodesicharamba yakasimba. Isu, sevanogadzira, takazvipira kuti tisvike kudiwa uku kuburikidza nekuenderera mberi kwekuvandudzwa uye kuvandudza, kuonaElectrodeanoramba achibvumikisa kuita kwemazuva anoMagetsi arc steelmaking.

Key Dealoways:

- Graphite Electrodeszvakakosha zvinodiwa mukatiMagetsi arc machira (eafs), kuitisa mafungu akanyanya kugadziraarcizvoMelts Scap Steel.

- Graphitendiyo yakanakisa zvinyorwa nekuda kwekukwira kwayokupisaKupokana, magetsi akanaka ekuita, anodzivisa kudzvinyirira, uye simba rakakura.

- Electrodeshuya mumakiredhi (rp, hp,Uhp) zvinoenderanachotoSimba;UHP Electrodesshandisa premium tsonoCokepakubata kwakanyanya.

- Kugadzira kuoma, kunosanganisira kusanganisa, kugadzira, kubheka,grafitifization(At ~ 3000 ° C), uye chaiyo machining yemakwikwi.

- Mhando yekudzora (kutarisa density, kuramba, kusimba, zviyero) zvinokoshesesa kuvimbikaElectrodeperformance uye kufungidzira kwekunwa muchisa chinyungudika.

- Kubata kwakakodzera, kuchengetedza, uye musangano uye musangano wejogo (kuchenesa, kururamisa torque) kwakakosha kudziviriraElectrodekukuvadza uye kuve nechokwadi chekushanda zvakanaka.

- Nhau dzakajairika dzinosanganisira kushandiswa (oxidation, kurasikirwa kweTip), kuputsa (thermal / mechanic kushushikana), uye matambudziko ejoin; kudzikisira kunosanganisira mhandoElectrodesuye maitiro akanaka ekushandisa.

- Kusarudza mutengesi kunoda kuongorora hunyanzvi hwekugadzira, masisitimu emhando, tsigiro yehunyanzvi, kutaurirana, logistics kuvimbika, uye kukosha kwese - kwete chete mutengo. Tarisa uone pachena uye kuvimba.

- Ramangwana reEAF Stbeelmakakingyakasimba, kutyaira kuenderera mberi kudiwa uye kuvandudzwa mukatiGraphite ElectrodeTekinoroji yesimba rakakwirirazvirotouye nekuvandudza kushanda.

Kutumira Nguva: 04-18-2025