In the intense heat of a melt shop, there is a specific sound that every production manager dreads: the sharp crack of a graphite column snapping inside the furnace. It is the sound of lost revenue. For those operating an Electric Arc Furnace (EAF), the graphite electrode is not merely a consumable; it is the primary transmission line for the colossal energy required to turn scrap into liquid steel. This article explores the critical specifications of uhp graphite electrodes, the mechanical necessity of 4tpi nipples, and how choosing the right supplier can stabilize your arc furnace operations.

What Defines the Basic Info and Product Description of a Top-Tier Graphite Electrode UHP?

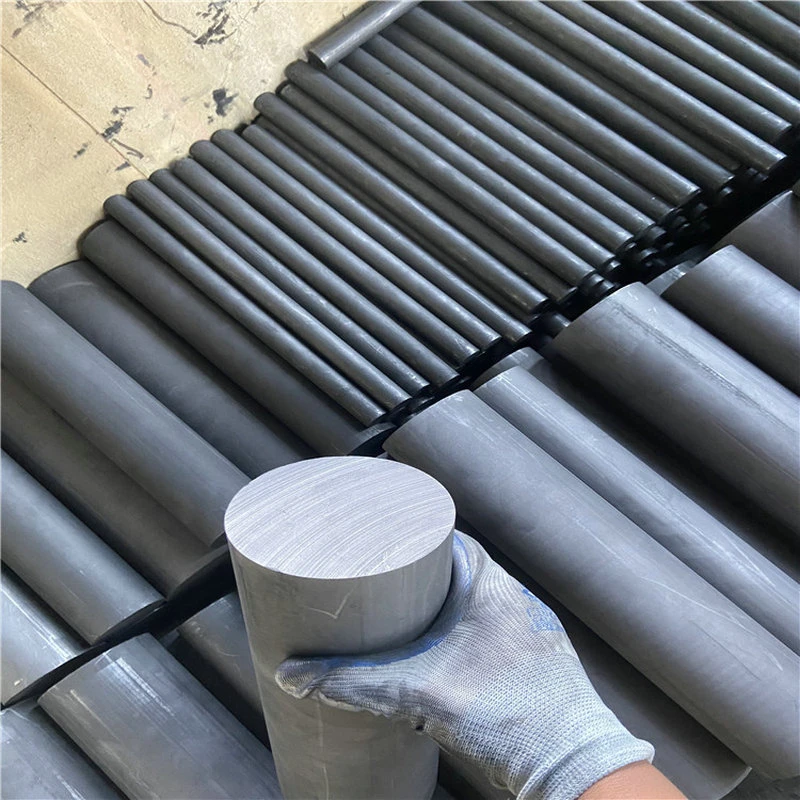

When you review the product description of a graphite electrode, you are looking at the DNA of your melt’s efficiency. A standard graphite electrode is a high-precision conductor manufactured from petroleum coke and needle coke, mixed with coal tar pitch. However, not all electrodes are created equal. They are generally divided into ordinary power graphite, high power, and uhp grade (Ultra High Power).

For modern steelmakers, the basic info you need to scrutinize involves bulk density, specific electrical resistance, and the Coefficient of Thermal Expansion (CTE). A uhp graphite electrode is characterized by low electrical resistance and high density. This allows it to carry extreme current loads (often exceeding 25 A/cm²) without overheating or suffering from rapid side oxidation.

If you are running a large-capacity eaf, you cannot compromise on the grade. Using a lower grade electrode in a high-power environment is a recipe for disaster. The uhp grade utilizes premium needle coke, which aligns during extrusion to provide superior thermal conductivity and mechanical strength. This structural integrity is what prevents the tip from "penciling" too quickly and keeps the arc stable during the bore-in phase.

Why is the UHP Grade Essential for Modern Electric Arc Furnace Operations?

The modern electric arc furnace is a beast that demands respect. As transformers get bigger and tap-to-tap times get shorter, the thermal shock applied to the graphite electrode uhp column increases exponentially. The uhp graphite material must withstand a temperature jump from room temperature to over 3000°C in seconds.

The uhp grade is specifically engineered for these conditions. It offers high mechanical strength and resistance to oxidation and thermal shock. In contrast, high power graphite or regular power grades are suited for smaller furnaces or ladle refining where the stress is lower. If you use a product that lacks the necessary mechanical properties, the electrode will spall, sending chunks of carbon into your steel bath. This not only alters the carbon chemistry of your steel but also risks breaking the arc.

Furthermore, uhp graphite electrodes facilitate a more stable electric arc. A stable arc means better energy transfer efficiency to the scrap, reducing the kWh per ton of steel produced. In an industry where margins are measured in pennies per pound, this efficiency is vital.

How Does the 4TPI Nipple Design Prevent Joint Failure in Your Arc Furnace?

The connection between electrode sections is the weakest link in the chain. This is where the nipple comes into play. In the past, 3TPI (3 threads per inch) was common, but for high-stress applications, the graphite electrode with 4tpi nipples has become the gold standard.

Why the shift to 4tpi? It comes down to surface area and friction. A 4tpi thread pitch provides more contact area between the nipple and the socket. This increased friction area creates a better locking mechanism, making the joint more resistant to the violent vibrations caused by scrap cave-ins and electromagnetic forces. A uhp graphite electrode with 4tpi is significantly less likely to loosen during operation.

If a joint loosens, electrical resistance spikes at the connection. This generates localized heat, which accelerates oxidation and burns through the threads. The result? The column separates, and the bottom section falls into the melt. By standardizing on graphite electrodes with nipples featuring the 4tpi or 4tpil (long) design, you are effectively insuring your operation against one of the most common causes of downtime.

What Mechanical Strength Properties Stop Graphite Electrodes with Nipples from Breaking?

Mechanical strength is often overlooked in favor of electrical properties, but it is equally important. A graphite electrode column is a long, heavy cantilever beam that endures massive side forces. The mechanical integrity of the uhp graphite depends on the quality of the raw material and the graphitization process.

High-quality graphite products must exhibit high flexural strength. This prevents the column from snapping when it hits a non-conductive piece of scrap (like a concrete block hidden in the charge) or when the furnace tilts. Additionally, the nipple must have a slightly higher CTE and strength than the electrode body to ensure it expands and locks the joint tightly as the furnace heats up.

We often see generic carbon graphite products that look good on paper but are easy to break in practice because they lack internal density uniformity. A reliable supplier will provide a product description that includes modulus of elasticity and flexural strength data, ensuring the product can handle the physical abuse of a modern melt shop.

How Do We Manufacture Anti-Oxidation Solutions for High Power Graphite Applications?

Oxidation is the enemy of graphite. In the eaf environment, oxygen attacks the carbon surface, turning it into CO2. This "side consumption" thins the electrode walls, weakening the column. To combat this, reputable manufacturers use advanced impregnation technology.

During manufacture, the graphite electrode is impregnated with special pitch under high pressure to fill the pores. This reduces the surface area available for oxygen to attack. Anti-oxidation coatings can also be applied to further shield the rod.

A graphite electrode from eaf uhp lines that has undergone proper impregnation will have a significantly lower consumption rate (kg/ton of steel). This high resistance to oxidation means you stop the furnace less often to add new sections, directly improving your "power-on" time. It is a solution that pays for itself in reduced downtime.

What is the Advantage of Sourcing Carbon Graphite Products from China?

China has emerged as the global leader in carbon and graphite products. The advantage of sourcing from China lies in the integrated supply chain. From the sourcing of needle coke to the final machining of the nipple, the entire ecosystem is localized.

As a supplier based in Hebei, Tuoda Carbon can offer a price about graphite electrodes graphite that is highly competitive without sacrificing quality. We have access to the same premium raw material sources as Western manufacturers but with more efficient processing costs.

However, buying from China requires due diligence. You need a supplier who understands the specific grade requirements of international mills. Whether you need High-power graphite electrode stock or premium UHP, the key is finding a partner who values long-term consistency over a quick sale.

Where are UHP Graphite Electrodes Most Widely Used in the Steel and Casting Industry?

The application of uhp graphite electrodes is primarily in the steel industry, specifically in Electric Arc Furnaces (electric arc furnace) and Ladle Furnaces. However, they are also widely used in the casting and foundry sectors for melting iron and steel alloys.

In alloy production, where chemical purity is paramount, the low ash content of uhp grade electrodes is critical. High ash can contaminate the melt with unwanted impurities. Graphite electrodes with nipples are also used in submerged arc furnaces for producing ferroalloys and silicon metal, although the grade requirements might differ slightly.

Understanding the specific application helps us recommend the right product. For example, a Regular Power Graphite Electorode might be perfectly suitable for a small foundry furnace but would fail instantly in a 100-ton EAF.

How to Find Details and Price About Graphite Electrodes That Match Your Specifications?

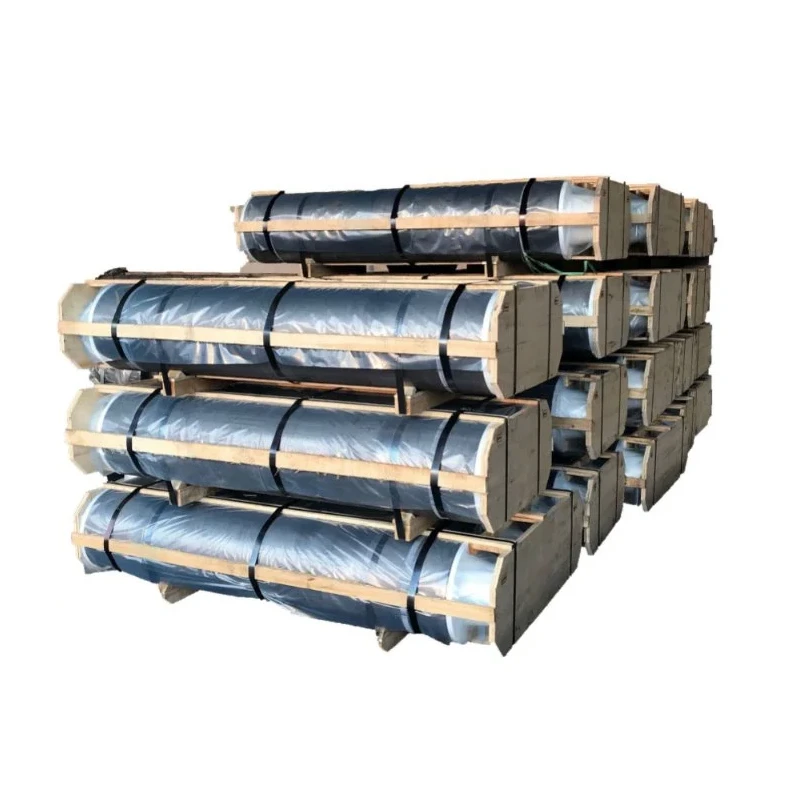

Procurement managers often struggle to find details and price that are transparent. To get an accurate quote, you need to provide more than just the diameter. You should specify the grade (UHP, HP, RP), the nipple type (4tpi, 3tpi, or 4tpil), and the length.

When requesting details and price about graphite, ask for the technical data sheet. Look for specific metrics:

- Bulk Density (g/cm³)

- Specific Electrical Resistance (μΩ.m)

- Flexural Strength (MPa)

- Ash Content (%)

Comparing these figures allows you to evaluate the price about graphite electrodes graphite effectively. A slightly more expensive electrode with good electrical conductivity and lower consumption will usually cost you less over the course of a year than a cheaper, lower-quality alternative.

Why is a Reliable Supplier Critical for Your EAF UHP Graphite Electrode Supply Chain?

The steel market is volatile. Prices for steel and scrap change daily. You cannot afford a supplier who is inconsistent. A reliable partner keeps stock of your specific sizes—whether it’s ultra-high power graphite electrodes or conductive graphite rod for electrodes—ensuring that you never run dry.

We encourage you to send your message to potential suppliers and gauge their response time. Do they ask about your furnace parameters? Do they offer technical support? A true partner helps you reduce consumption and optimize your process. We are not just selling a black cylinder; we are selling uptime.

Related Categories: Are Rods and Mineral Components the Same as Electrodes?

It is important to distinguish between graphite electrode products and related categories. While they are all carbon-based, a rod used for gouging or small-scale electrolysis is very different from an eaf uhp graphite electrode.

- Graphite Rods: Smaller, often used for casting repair or chemical processes.

- Mineral Components: Raw materials like calcined petroleum coke used as carbon raisers.

- Electrode Paste: Used in Soderberg furnaces, different from pre-baked electrodes.

If you are looking for products graphite electrode related, ensure you are in the right category. UHP graphite electrodes are specialized conductor tools designed for the massive energy transfer of an arc. Confusing these with general graphite products can lead to costly procurement errors.

Key Takeaways for Steelmakers

- Grade Selection: Always match the electrode grade (UHP vs. HP) to your furnace transformer capacity. UHP graphite is essential for high-power EAFs.

- Nipple Mechanics: Utilize 4tpi or 4tpil nipples for large diameter electrodes to ensure a secure, vibration-resistant lock.

- Anti-Oxidation: Choose impregnated electrodes to reduce side oxidation and lower overall consumption rates.

- Supplier Vetting: Look for transparency in basic info and technical specs. A reliable supplier provides data on density, resistance, and ash.

- Cost vs. Value: Don’t just look for the lowest price. Calculate the total cost of ownership based on consumption efficiency and breakage rates.

- Storage: Keep electrodes dry and use proper mechanical handling to prevent damage before they even reach the furnace.

By focusing on these technical pillars, you can ensure that your electric arc burns bright, your steel quality remains high, and your operational costs stay low.

Post time: 02-11-2026