In the intense world of industrial metallurgy, the electric arc furnace (EAF) is the beating heart of production. At the core of this beast lies the graphite electrode, a critical component responsible for channeling massive amounts of energy to melt scrap metal. However, for anyone managing a steel mill or foundry, there is a constant, recurring reality: these electrodes need to be replaced. It is not a sign of failure; it is a fundamental part of the process. But have you ever stopped to wonder why? Why does a material known for its incredible heat resistance vanish into thin air?

The answer lies in a fascinating mix of physics and chemistry. While graphite is chosen for its ability to withstand extreme conditions, it is not invincible. Understanding the specific mechanisms that cause these electrodes to degrade—from oxidation to mechanical stress—is vital for optimizing efficiency and managing costs. This guide will walk you through the science of why graphite electrodes need constant attention and regular replacement.

What is the Role of the Graphite Electrode in the Furnace?

Before we dive into why they disappear, we must understand what they do. A graphite electrode acts as a massive conductor. It transfers electricity from the power source into the furnace. When the electrical current leaps from the tip of the electrode to the metal scrap, it creates an electric arc. This arc generates intense heat, reaching temperatures capable of melting steel in minutes.

Graphite is the material of choice because it is an excellent conductor of electricity and has high thermal resistance. It remains solid when other materials would melt. However, acting as the bridge between raw power and molten metal takes a toll. The electrode is essentially a consumable tool. It is gradually consumed during the electrolysis process or the smelting process, necessitating a strict schedule of replacement.

How Does Chemistry Drive the Need for Replacement?

The primary reason electrodes need to be replaced comes down to basic chemistry. The environment inside a furnace is hostile. When the furnace operates at high temperatures, the carbon in the graphite becomes highly reactive.

The most significant factor here is oxidation. As the process heats up, oxygen enters the mix. The carbon atoms in the graphite electrode react with oxygen in the atmosphere to form carbon dioxide (CO2) and carbon monoxide (CO). This is not a physical breaking; it is a chemical transformation. The solid carbon turns into gas.

This reaction eats away at the surface of the electrode, causing it to thin out. This is known as sidewall oxidation. As the diameter of the electrode decreases, its ability to carry current diminishes, and its structural integrity weakens. Eventually, the quantity of graphite lost to this oxidation process means the electrodes need to be swapped out for fresh ones.

Why Do High Temperatures Accelerate Electrode Consumption?

Temperature is the catalyst for almost everything that happens in an EAF. High temperatures drastically speed up the rate at which the graphite consumes. The hotter the furnace, the faster the chemical reactions occur.

In the smelt zone, specifically at the tip of the electrode, the heat is most intense. Here, the graphite can actually sublimate—meaning it turns directly from a solid into a vapor—due to the extreme arc temperatures (which can exceed 3000°C). This tip consumption shortens the column. To maintain the arc distance and the voltage, the system lowers the electrode column. Consequently, the electrodes need to be replaced to maintain the necessary length for the operation. If you do not replace them, you simply run out of conductive material to reach the melt.

How Does the Extraction of Aluminium Differ from Steel?

While we often talk about steel, graphite and carbon blocks are also crucial in the extraction of aluminium. However, the setup is slightly different. In aluminum production, the process takes place in a pot or cell. Here, carbon anodes (positive electrodes) are used.

In this electrochemical process, alumina is dissolved in molten cryolite. When electricity passes through, the oxygen from the alumina reacts with the carbon anode to form carbon dioxide. This means the anode is chemically destined to be destroyed to produce the metal. It is not just a side effect; it is part of the reaction equation. These anodes are consumed at a steady rate and must be replaced regularly to ensure the process continues. If they are not replaced, the voltage rises, energy consumption spikes, and the reduction of alumina stops.

Can Mechanical Stress Cause the Graphite Electrode to Crack?

Aside from chemistry and heat, physical forces play a huge role. An EAF is a violent environment. Massive pieces of scrap metal can shift and collapse (called a "scrap cave-in"). If heavy scrap hits the electrode, it can snap. This breakage immediately stops production.

Furthermore, thermal shock is a real danger. The electrode experiences massive temperature swings. The rapid expansion and contraction can cause the material to crack or spall (flake off). When a piece of the electrode breaks off and falls into the melt, it increases the carbon content of the steel (which might not be desired) and, more importantly, it forces an unscheduled replacement. High-quality High-power graphite electrodes are designed with specific mechanical properties to resist this, but no material is immune to physics.

What Happens if You Don’t Replace Electrodes Regularly?

Ignoring the need for regular replacement or trying to run an electrode down to the nub is a recipe for disaster. As the electrode thins due to oxidation, its electrical resistance increases. This leads to higher energy consumption because the system has to work harder to push the current through a thinner conductor.

If the electrode becomes too short or thin, you lose stability in the arc. This affects the melt quality and the efficiency of the furnace. In extreme cases, the holder (the clamp holding the electrode) might get too close to the molten bath, risking damage to expensive equipment. Therefore, electrodes need to be replaced on a strict schedule to protect the furnace and ensure consistent product quality.

How Can You Reduce the Frequency of Replacement?

Every plant manager wants to reduce consumption. While you cannot stop the laws of physics, you can optimize them. The key is reducing oxidation.

Many modern electrodes used in furnaces come with coatings or specific density formulations to resist oxidation. Cooling systems, such as water spray rings, help lower the sidewall temperature of the electrode, slowing down the reaction with oxygen. Additionally, optimizing the regulation system of the furnace to prevent mechanical breakage helps. However, the most effective way to reduce the frequency of changes is to use the correct grade of product, such as a Regular Power Graphite Electorode for standard furnaces or UHP grades for high-intensity operations.

How Does Electrode Quality Affect Efficiency?

Not all graphite is created equal. The porosity, density, and purity of the graphite determine how fast it will oxidize. A porous electrode has more surface area exposed to internal oxidation, causing it to crumble faster.

High-quality UHP graphite electrodes are denser and stronger. They conduct electricity better (less resistance) and stand up to high temperatures and chemical attacks more effectively. Investing in better quality means the electrodes need changing less often, which translates to less downtime. In the industrial world, downtime is the most expensive cost of all.

What is the Process for Changing an Electrode?

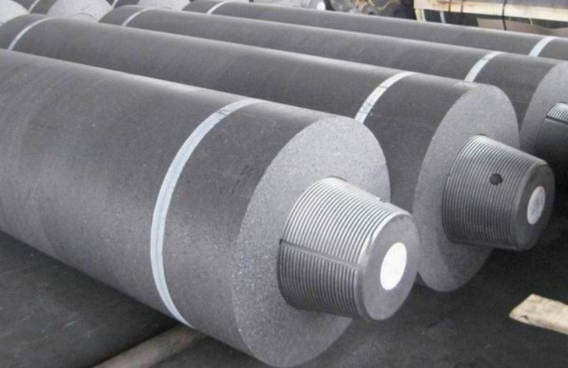

The replacement process is a well-choreographed routine in steel mills. It involves adding a new section to the top of the electrode column. Electrodes are manufactured with threaded sockets at each end. A connecting pin, or nipple, is used to join a new electrode to the existing column.

This "on-the-fly" addition allows the furnace to keep running with minimal interruption. As the bottom is consumed in the melt, the column is lowered, and new lengths are added to the top. This continuous feed system means that while the material is replaced regularly, the furnace doesn’t always have to go cold to do it.

How Does the Cathode Factor into the Equation?

In aluminum cells, while the anode is consumed rapidly, the cathode (the bottom lining of the cell) lasts much longer, but it still degrades. The cathode conducts the electricity out of the cell. Over time, sodium and molten metal penetrate the carbon lining.

This penetration causes swelling and cracking. While the anode might last weeks, a cathode might last years. However, when the cathode fails, the entire pot must be taken out of service for a major rebuild. So, while less frequent, cathode maintenance and replacement are massive events in the life of a smelter.

Summary

The lifecycle of a graphite electrode is a testament to the harsh realities of heavy industry. They are champions of heat and power, sacrificing themselves to build the world around us.

Here are the key takeaways to remember:

- Chemistry is the Driver: The primary reason electrodes need to be replaced is oxidation. Carbon reacts with oxygen at high heat to produce CO2 and gas, physically consuming the material.

- Heat Accelerates Loss: High temperatures increase the rate of chemical reactions and can cause sublimation at the tip.

- Mechanical Risks: Scrap movement and thermal shock can cause breakage, necessitating immediate replacement.

- Efficiency Matters: Worn electrodes have higher resistance and lower efficiency. Regular replacement ensures the furnace runs at optimal power.

- Quality Counts: Using high-density graphite reduces porosity and slows down the oxidation process, saving money in the long run.

- Different Processes: In aluminum production, the anode is consumed to remove oxygen from alumina, while in steel EAF, the electrode generates the arc to melt scrap.

Understanding these factors helps in selecting the right materials, like a durable conductive graphite rod, ensuring your operations remain smooth, safe, and profitable.

Post time: 12-23-2025