Step into almost any high-tech manufacturing facility, from a steel mill to a semiconductor plant, and you will find an unsung hero working tirelessly in the background: the humble graphite block. As Allen, the owner of a factory with seven production lines dedicated to crafting precision graphite products, I’ve spent my life working with this incredible material. It’s essentially a solid block of pure carbon, but through a remarkable industrial process, it’s transformed into one of the most versatile and essential materials of the modern age.

For procurement officers and business owners like my friend Mark Thompson in the USA, understanding where and why graphite blocks are used is key to making smart purchasing decisions. This article will be your definitive guide. We will explore the incredible journey of a graphite block from a simple carbon raw material to a critical component in everything from nuclear reactors to the smartphone in your pocket. By the end, you’ll see why this unassuming black block is truly a cornerstone of industry.

What Exactly is a Graphite Block and How is it Made?

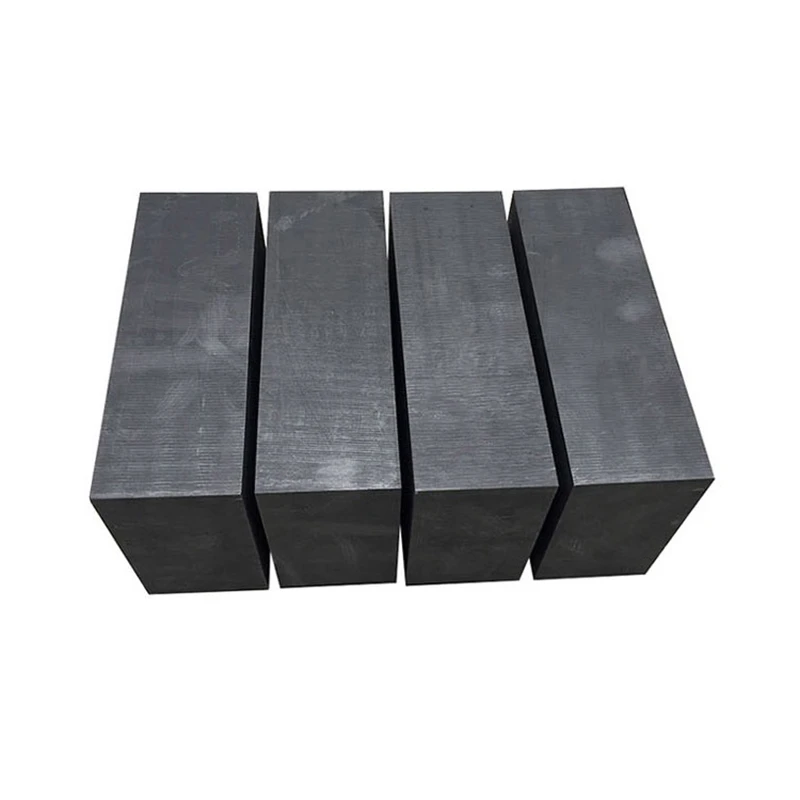

At its simplest, a graphite block is a solid, rectangular or cylindrical piece of high-purity graphite. But what is graphite? It is a natural form of carbon, just like diamonds. The magic lies in how the carbon atoms are arranged. In graphite, they form a layered structure, like a deck of cards. These layers can easily slide past one another, which gives graphite its characteristic softness and lubricity. While natural graphite is mined from the earth, the vast majority of high-performance graphite blocks used in industry are man-made.

The creation of these synthetic graphite blocks is a marvel of material science. The process begins with a carefully selected raw material, usually high-purity petroleum coke, which is mixed with a binder like coal tar pitch. This mixture is molded into a block and then baked in a furnace for weeks to create a hard, dense carbon block. The final and most critical step is graphitization. The block is heated in a special graphitizing furnace to an astonishingly high temperature of nearly 3,000°C (5,400°F). This intense heat forces the randomly arranged carbon atoms to realign themselves into the perfect, ordered, layered structure of graphite. This process gives us a material with exceptional purity and predictable mechanical properties.

Why are Synthetic Graphite Blocks a Go-To for High-Tech Industries?

While natural graphite is useful, synthetic graphite blocks are the material of choice for almost all demanding industrial applications. The reason is simple: control. The synthetic process allows us to control every aspect of the final product, from its purity and density to its grain size. This results in a material with incredibly consistent and predictable physical and chemical properties.

In high-tech fields like semiconductor manufacturing or aerospace, you cannot have variations in your materials. You need to know exactly how a component will behave under high-temperature stress or when exposed to corrosive chemicals. Synthetic graphite blocks offer this reliability. We can tailor the properties of the block to a specific application, creating a material that is perfectly suited for its job. This level of precision and consistency is something that mined, natural materials simply cannot match, making synthetic graphite the undisputed champion for high-performance applications.

What are the Primary Uses of Graphite Blocks in Metallurgy and Foundries?

The metallurgical industry is one of the largest consumers of graphite blocks, and for good reason. The material’s incredible high-temperature resistance and chemical stability make it perfect for handling molten metals. One of the most common uses of graphite blocks is as a mold for casting. Molten metal can be poured directly into a graphite mold, and because graphite has very low wettability and adhesion, the solidified metal part can be removed easily without sticking.

They are also machined into crucibles. A graphite crucible is a container used to smelt and hold molten metals in a furnace. Graphite’s ability to withstand the intense heat without degrading or contaminating the metal makes it an ideal choice. In the world of powder metallurgy, graphite blocks used as molds are essential for a process called sintering. Metal powders are placed in a graphite mold and heated in a furnace, causing the particles to fuse together into a solid part. From the smallest foundry to the largest steel mill, graphite is an essential tool for shaping and forming metals.

How are Graphite Blocks Used as Electrodes in EDM and Furnaces?

Beyond just holding hot metal, graphite blocks are widely used as a raw material for making electrodes due to their excellent electrical and thermal conductivity. One of the most high-precision applications is in Electrical Discharge Machining (EDM). In this process, a graphite block is meticulously machined on a CNC machine into a complex, detailed shape. This shaped electrode is then used to create molds from hardened steel. A powerful electrical spark jumps from the graphite electrode to the steel, eroding it away in a highly controlled manner, creating a perfect inverse of the electrode’s shape. The EDM electrodes we make for our clients are used to produce molds for everything from car parts to medical devices.

On a much larger scale, graphite blocks are the foundational material for the massive graphite electrodes used in electric arc furnaces for steel recycling. While these are often manufactured as monolithic cylinders, the underlying technology and material properties are the same. The graphite’s ability to conduct enormous amounts of electricity and withstand the arc’s heat is what makes modern steel recycling possible. Many specialty High-power graphite electrodes begin their life as a high-quality graphite block.

Can You Explain the Critical Role of Graphite Blocks in the Semiconductor Industry?

The device you are reading this on would not exist without graphite. The semiconductor industry relies heavily on high-purity graphite blocks for several critical steps in the manufacturing of computer chips. The process of "growing" the large silicon crystals that are sliced into wafers happens inside a special furnace, and many of the components inside this furnace are made from graphite.

Graphite blocks are machined into parts called susceptors, which hold the silicon wafers, as well as heating elements that provide the necessary heat. The reason graphite is used is twofold. First, its high-temperature stability ensures it doesn’t contaminate the ultra-pure silicon. Second, its high thermal conductivity is essential for maintaining perfect temperature uniformity across the wafer. Any hot or cold spots would ruin the delicate crystal structure. Graphite is also used to make heat sinks and other components that aid in heat dissipation during the later stages of semiconductor manufacturing. In this world of microscopic precision, graphite’s reliability is indispensable. The same properties make it ideal for manufacturing other precise components like conductive graphite rods.

Are Graphite Blocks Really Used in Nuclear Reactors?

Yes, and their role is absolutely critical. Ever since the dawn of the nuclear age, graphite blocks have been a key component in the core of many types of nuclear reactors. The application of graphite here is fascinating, serving two vital functions simultaneously.

First, graphite acts as a moderator. During a nuclear fission reaction, fast-moving neutrons are released. To sustain the chain reaction, these neutrons need to be slowed down. The carbon atoms in the graphite block are perfect for this job. When the fast neutrons collide with the carbon atoms, they lose energy and slow down, allowing them to cause further fission reactions in a controlled manner. Second, graphite serves as a structural material and reflector. The core of the reactor is often built from thousands of precisely machined graphite blocks, forming a stable structure that can withstand the intense heat and radiation. These blocks also help to reflect neutrons back into the core, making the reactor more efficient.

What is the Emerging Use of Graphite Blocks in Clean Energy?

As the world shifts towards a greener future, graphite is finding new and exciting roles to play. The most significant of these is in energy storage, specifically in lithium-ion batteries. While you won’t find a solid graphite block inside your phone, the graphite powder that makes up the battery’s anode is often produced by grinding down high-purity graphite blocks.

The anode is the negative electrode of the battery, and in lithium-ion batteries, it’s almost always made of graphite. The unique layered structure of graphite is perfect for a process called intercalation. During charging and discharging, lithium ions snuggle in between the layers of carbon. This ability to safely store and release lithium ions is what gives these batteries their high energy density and long cycle life. From electric vehicles to grid-scale energy storage, the demand for high-quality anode materials made from graphite is exploding. Additionally, graphite is being used to make bipolar plates for fuel cells, another promising clean energy technology.

How Do Graphite Blocks Perform in Aerospace and High-Temperature Applications?

When you need a material that can handle some of the most extreme conditions imaginable, you turn to graphite. The aerospace industry relies on graphite blocks for components that must perform flawlessly under extreme temperatures. Rocket nozzles, for example, are often machined from high-density graphite. They must channel exhaust gases that are thousands of degrees hot without melting or eroding. Graphite’s incredibly high melting point (it technically sublimes, not melts, at around 3,652°C or 6,606°F) and thermal stability make it one of the few materials that can do the job.

Beyond rockets, graphite is essential for heat treatment processes. In industrial furnaces used to harden metals or grow crystals, the internal components—like liners, fixtures, and graphite heating elements—are often made from graphite. Its ability to withstand the heat and its low thermal expansion ensure that the furnace components remain dimensionally stable, providing a reliable and long-lasting solution for high-temperature work. It is for these demanding applications that our factory produces a wide range of graphite products.

What Key Properties Make a Graphite Block So Versatile?

As we’ve seen, graphite blocks are used across an astonishingly wide range of industries. This versatility comes from a unique combination of properties that are rarely found together in a single material.

"I’ve been in this business for a long time, and I still marvel at graphite. It’s a fantastic electrical conductor but also a great thermal conductor. It’s soft enough to machine easily but strong enough to survive in a rocket engine. It’s this unique combination that makes it an engineer’s dream material." – Allen, Factory Owner

| Property | Description | Key Benefit |

|---|---|---|

| High Thermal & Electrical Conductivity | Efficiently transfers heat and electricity. | Ideal for heating elements, electrodes, and heat sinks. |

| Exceptional High-Temperature Stability | Retains its strength at temperatures where metals would melt. | Perfect for furnace linings, crucibles, and molds. |

| Excellent Chemical Stability | Highly resistant to corrosion from acids, bases, and molten metals. | Ensures purity in metallurgical and semiconductor processes. |

| Low Coefficient of Thermal Expansion | Does not expand or contract significantly with temperature changes. | Provides dimensional stability for high-precision molds and fixtures. |

| Self-Lubricating Properties (Lubricity) | The layered structure gives it natural lubricant properties. | Used for bearings and seals that operate in high-temperature environments. |

| Outstanding Machinability | Despite being abrasive, it can be machined into complex shapes. | Allows for the creation of intricate custom graphite components and EDM electrodes. |

How Do You Choose the Right Graphite Block for Your Application?

With so many forms of graphite available, choosing the right graphite block is crucial for success. The most important factor is the grade, which is primarily determined by the grain size of the material. A coarse-grain block might be fine for a simple furnace lining, but for a high-detail EDM electrode or a semiconductor part, you would need an ultrafine-grain grade to achieve the necessary precision and surface finish.

The best advice I can give anyone sourcing this material is to talk to a knowledgeable manufacturer. A good supplier won’t just sell you a block; they will work with you to understand your specific needs. They can advise you on the right grade, help design custom graphite components, and provide the technical data to back up their recommendations. By partnering with an experienced factory, you ensure that you get a material that is not just a block of carbon, but a high-performance engineering solution tailored to your needs, like a High strength graphite block.

Key Takeaways

The graphite block is a truly remarkable material, a simple block of carbon transformed into a high-tech enabler. Its unique combination of properties makes it indispensable across a vast industrial landscape.

Here are the most important things to remember:

- Foundation of Industry: Graphite blocks are used as a foundational material in metallurgy, EDM, semiconductor manufacturing, nuclear energy, aerospace, and clean energy.

- Made for Performance: High-performance synthetic graphite blocks are engineered through a graphitization process, giving them superior and consistent properties.

- The Heat is On: Graphite’s primary advantage is its incredible stability and strength at high temperatures, making it ideal for furnaces, molds, and crucibles.

- An Excellent Conductor: Its high electrical and thermal conductivity makes it the material of choice for electrodes, heating elements, and heat sinks.

- Grade Matters: The performance of a graphite block is highly dependent on its grade. Always choose a grade that matches the precision and demands of your application.

- Partner with Experts: Working directly with an experienced manufacturer is the best way to ensure you get the right quality and type of graphite for your project’s success.

Post time: 11-05-2025