As a procurement officer or steel mill owner, you know that the quality of your graphite electrodes directly impacts your furnace’s efficiency, energy consumption, and overall profitability. You make crucial purchasing decisions every day, often sourcing from overseas. But have you ever wondered what truly goes into creating the high-performance electrodes you rely on? Understanding the intricate graphite electrode manufacturing process is not just for engineers; it’s vital knowledge that empowers you to vet suppliers, ask the right questions, and secure a product that delivers on its promises. This guide will walk you through every critical stage, from raw material selection to final inspection, giving you the inside look from a factory perspective. My name is Allen, and after years of overseeing our seven production lines here in China, I want to demystify this process for you.

What Raw Materials Are Essential for High-Quality Graphite Electrodes?

The journey of a world-class graphite electrode begins long before it reaches any machine. It starts with the meticulous selection of the raw material. You can’t build a strong house on a weak foundation, and similarly, you can’t produce a durable, efficient electrode from subpar components. The primary ingredient is high-quality needle coke, a premium grade of petroleum coke derived as a byproduct of the oil refining process. Its unique, needle-like crystalline structure is essential for producing electrodes with low electrical resistance and excellent thermal shock resistance, which are critical for the harsh environment inside an electric arc furnace.

The second key component is coal tar pitch, which acts as a binder. This material is mixed with the needle coke to form a paste that can be molded and shaped. The quality of the coal tar pitch is just as important as the coke; it must have the right viscosity and chemical properties to ensure the carbon particles are held together firmly throughout the demanding heating stages of the production process. As a manufacturer, we’ve learned that a consistent and reliable supply chain for these raw materials is non-negotiable. Any impurity or variation can compromise the integrity of the final graphite electrode, leading to cracks, breaks, or poor performance in your furnace.

How Are Raw Materials Prepared and Mixed for Optimal Consistency?

Once we have sourced the best raw materials, the raw material preparation stage begins. This isn’t as simple as just dumping everything into a mixer. The needle coke is first crushed, screened, and ground into a carefully controlled mix of particle sizes. This is a crucial step because the distribution of different-sized particles determines the final density and mechanical strength of the electrode. Think of it like making concrete: you need a combination of large stones, smaller gravel, and fine sand to fill every void and create a solid, strong structure. The same principle applies here. Our automated systems ensure this particle-size recipe is followed with extreme precision for every single batch.

After sizing, the coke particles are heated and then blended with the molten liquid pitch in large, powerful mixers. This mixing is done at a specific temperature to ensure the pitch coats every particle thoroughly, creating a uniform, dough-like paste. The quality of this mixture is paramount. If it’s not homogenous, the resulting graphite electrode will have weak spots, leading to potential failures during operation. This is one of the first major quality control checkpoints in the graphite electrode manufacturing process. We take samples from each batch to test for consistency before it’s allowed to move to the next stage: molding.

What Happens During the Molding and Extrusion Stage?

With the raw material paste prepared, the next step is to give the electrode its initial form. This is accomplished through a process called extrusion. The heated paste is fed into a powerful extrusion press, which is essentially a giant hydraulic machine that forces the material through a die. This die determines the diameter of the cylindrical green electrode (at this stage, it’s called "green" because it is unbaked). The pressure involved is immense, compacting the material to achieve a high initial density and align the needle coke particles along the length of the electrode. This alignment is critical for achieving optimal electrical conductivity.

For very large electrodes, a different molding method called isostatic pressing may be used. In this technique, the material is placed in a flexible mold and subjected to high pressure from all directions by a liquid, resulting in an extremely uniform density throughout the block. Regardless of the method, the goal is the same: to create a solid, well-formed cylindrical rod that is free of cracks or internal defects. These extruded rods, now cut to specific lengths, are carefully cooled to solidify the pitch binder before they are moved to the baking furnaces. The precision of the machine work at this stage sets the dimensional foundation for the final product.

Why Is the Baking Process So Critical for Electrode Strength?

The "green" electrode is still relatively fragile. To give it strength and transform the pitch binder into solid carbon, it must undergo a meticulous baking process. This is one of the longest and most energy-intensive stages in manufacturing graphite electrodes. The extruded rods are carefully placed in a large, pit-type baking furnace. They are packed with a protective material, like metallurgical coke, to provide support and prevent deformation as the pitch softens before it hardens. This packing material also helps ensure a slow, uniform distribution of heat.

The heating process is incredibly slow and precisely controlled, lasting for several weeks. The temperature is gradually raised to around 800-1000 degrees Celsius. This slow ramp-up allows the volatile materials in the pitch to escape without creating cracks or fissures in the electrode. During this thermal treatment, the pitch binder is carbonized, converting it into a strong "coke bridge" that firmly bonds the needle coke particles together. Rushing this stage is a common mistake made by lower-quality manufacturers and it inevitably results in a weak electrode material that cannot withstand the stresses of an arc furnace. After reaching the peak temperature, the electrodes undergo a similarly slow cooling process.

How Does Impregnation Enhance Electrode Density and Performance?

After the first baking cycle, the baked electrodes are hard and strong, but they are also porous. The process of converting the liquid pitch to solid carbon creates a network of tiny pores, or voids, which can negatively impact the electrode’s density and conductivity. To solve this, the electrodes may undergo an impregnation process. This involves placing the baked electrode in an autoclave, a high-pressure vessel. The air is vacuumed out of the pores, and then a special, low-viscosity liquid pitch is introduced under high pressure, forcing it deep into the internal structure of the electrode.

This impregnation step effectively fills the voids, significantly increasing the density and mechanical strength of the graphite electrode. After impregnation, the electrode must go through a second baking cycle, or rebake, to carbonize the new pitch that has been added. For high-performance grades like UHP (Ultra-High Power) electrodes, this impregnation and rebake cycle may be repeated two or even three times to achieve the extremely high density and strength required for the most demanding electric arc furnace applications. Each cycle adds cost and time, which is why higher-grade electrodes are more expensive, but the performance gains are substantial.

What is Graphitization and How Does It Create a Superior Electrode?

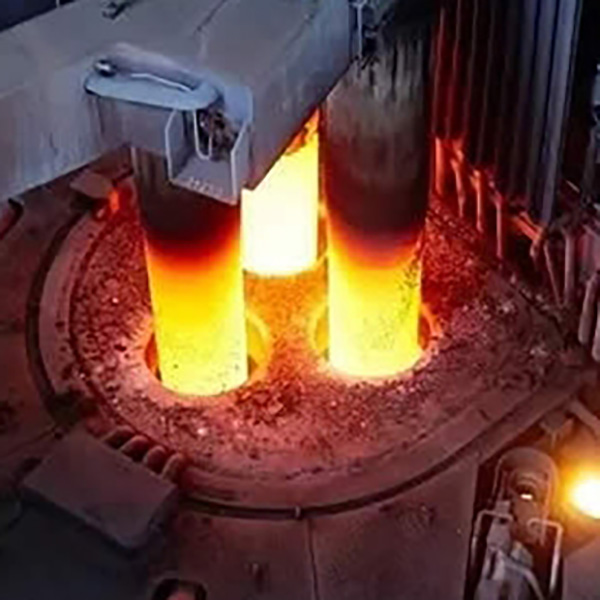

At this point, we have a dense, hard carbon electrode, but it is not yet graphite. The final transformation happens in the most critical and impressive stage of all: graphitization. This process converts the amorphous, disorganized carbon into the highly ordered, crystalline structure of graphite, which is what gives the electrode its incredibly low electrical resistance and superior thermal properties. The baked and impregnated electrodes are carefully loaded into a special electric furnace, typically a lengthwise Acheson furnace. They are surrounded by granular graphite to act as a resistive heating element.

An extremely powerful electric current is passed through the furnace load, causing the electrodes to be heated to temperatures approaching 3000°C—hotter than the melting point of most metals. This intense heat provides the energy needed to rearrange the carbon atoms into the parallel-layered planes that define the graphite structure. This graphitizing process can take several weeks from heating to cooling. It is this final, extreme thermal treatment that transforms a simple carbon block into a high-performance graphite electrode ready for the rigors of modern steelmaking. The resulting graphitized product has the properties that make it an indispensable tool for every electric arc furnace.

What is the Role of Precision Machining for the Final Electrode?

After the long graphitization process, the graphitized electrodes, now called "blanks," are ready for final shaping. While they are already in a cylindrical shape, they require precision machining to meet the exact specifications for use in an arc furnace. The electrodes are machined on large, specialized lathes. This process ensures the body of the electrode is perfectly straight and has a smooth surface finish. Most importantly, this is where the threaded sockets are cut into each end of the electrode.

These sockets are crucial, as they allow individual electrodes to be connected to form a continuous column that can be fed into the furnace. The sockets are machined to an incredibly tight tolerance to ensure a secure and electrically efficient connection when joined with a graphite connecting pin (nipple). Poorly machined threads can lead to loose joints, overheating, and ultimately, a broken electrode column—a costly and dangerous event in a steel mill. The machining ensures that each electrode will fit perfectly with the next, providing both structural integrity and a seamless path for the massive electric current used in the production of steel. Many electrodes also receive a special surface coating to improve their oxidation resistance.

How Do We Implement Rigorous Quality Control Throughout Production?

For a buyer like Mark, who is rightly concerned about product quality and fraudulent certificates, understanding a supplier’s quality control (QC) process is paramount. Rigorous quality control measures are implemented at every single stage of the manufacturing process of graphite electrodes, not just at the end. It begins with testing the raw materials used for purity and consistency. During mixing and extrusion, we constantly monitor the paste’s properties. After baking and impregnation, samples are tested for density and strength.

The most comprehensive testing occurs after graphitization. Each electrode is inspected for any visual defects, cracks, or imperfections. We then take samples from representative electrodes in each batch and test them in our on-site laboratory for key physical properties:

- Bulk Density: Ensures the electrode is properly compacted.

- Electrical Resistivity: A key measure of its efficiency.

- Flexural Strength: Measures its ability to resist breakage under load.

- Modulus of Elasticity: Indicates its stiffness.

- Coefficient of Thermal Expansion (CTE): Critical for thermal shock resistance.

These tests ensure the final graphite electrodes meet or exceed international standards for their grade (e.g., RP, HP, UHP). Every shipment is accompanied by a genuine material test report detailing the properties of that specific production batch, giving you complete traceability and peace of mind.

What Are the Different Grades of Graphite Electrode?

Not all electric arc furnace operations are the same, so graphite electrodes are made in different grades to match specific performance requirements. Understanding these grades is key to selecting the most cost-effective option for your application.

| Grade | Full Name | Current Density (A/cm²) | Key Characteristics | Typical Application |

|---|---|---|---|---|

| RP | Regular Power | < 17 | Lower density, higher electrical resistance. | Used in smaller, less demanding ladle furnaces or for smelting silicon metal. |

| HP | High Power | 18 – 25 | Good density and strength, moderate electrical resistance. A versatile workhorse. | Used in high-power electric arc furnaces for steelmaking and foundries. |

| UHP | Ultra-High Power | > 25 | Very high density, extremely low electrical resistance, excellent thermal shock resistance. | Used in the most demanding, high-output ultra-high-power electric arc furnaces. |

The primary difference between these grades lies in the raw material used (UHP requires premium needle coke) and the number of impregnation cycles they undergo. A UHP electrode is denser, stronger, and more conductive, allowing it to carry a much higher electric current without overheating or breaking. While more expensive upfront, using the correct grade like an Ultra-high power graphite electrode for a demanding application leads to lower overall consumption and more efficient steelmaking.

How Can You Identify a Reliable Graphite Electrode Manufacturer?

As an experienced procurement professional, you know that finding a trustworthy supplier is about more than just a low price. It’s about finding a partner. When evaluating a graphite electrode manufacturer, especially from overseas, here are a few things I, as a factory owner, would recommend you look for:

- Transparency: A good supplier will be open about their manufacturing process. They should be willing to share details about their raw material sourcing, their QC procedures, and provide authentic test reports.

- Experience and Expertise: Look for a company with a proven track record. How long have they been in business? Do they have experience exporting to your country? Our experience shipping to the USA, Europe, and Australia means we understand the logistics and documentation required.

- Comprehensive Product Line: A factory that produces not just electrodes but also related products like a high strength graphite block or a Conductive graphite rod for electrodes often has deeper technical expertise.

- Responsiveness: Communication is key. Your sales contact should be knowledgeable and responsive, able to answer both commercial and basic technical questions. This helps avoid the communication pain points you may have experienced. They should provide clear updates on production and shipping schedules to prevent delays.

- Willingness to Be Vetted: Reputable manufacturers welcome audits and inspections. They are confident in their processes and have the ISO certifications to prove it.

The process of manufacturing graphite electrodes is a complex blend of science, engineering, and experience. By understanding these key steps, you are better equipped to evaluate suppliers, verify quality, and ensure the electrodes you purchase, such as a High-power graphite electrode, deliver the performance your operation demands.

Key Takeaways to Remember

- Raw Materials are Foundation: The quality of a graphite electrode is determined before manufacturing even begins. Premium needle coke and coal tar pitch are non-negotiable for high performance.

- Baking is a Marathon, Not a Sprint: The slow, multi-week baking process is essential for creating a strong carbon bond and preventing internal defects. Rushing this stage compromises the electrode’s integrity.

- Impregnation Boosts Density: For HP and UHP grades, forcing pitch into the electrode’s pores through impregnation is crucial for increasing density, strength, and conductivity.

- Graphitization Unlocks Performance: The extreme heat of the graphitization furnace (around 3000°C) is what transforms amorphous carbon into highly conductive graphite.

- Quality Control is Continuous: Reliable manufacturers test materials at every stage, from raw inputs to the final machined electrode, ensuring consistency and performance.

- Machining Precision Matters: The accuracy of the threaded sockets is critical for the safety and efficiency of the entire electrode column in the arc furnace.

Post time: 08-18-2025