The modern steel industry relies heavily on the electric arc furnace (EAF), a powerful and efficient tool for recycling scrap steel. At the very heart of this technology is the graphite electrode, a seemingly simple component that performs an extraordinary task. For procurement officers like Mark Thompson, who navigate the global market to source these critical components, understanding their nuances is paramount. This article is your comprehensive guide. As a factory owner with over a decade of experience in manufacturing and exporting these products, I, Allen, want to pull back the curtain. We will explore everything from the fundamental science of the electric arc to the practical concerns of quality inspection, logistics, and minimizing consumption. This guide will empower you with the knowledge to make informed purchasing decisions, avoid common pitfalls, and build stronger partnerships with your suppliers.

What Exactly is a Graphite Electrode and Why is it Essential for an Electric Arc Furnace?

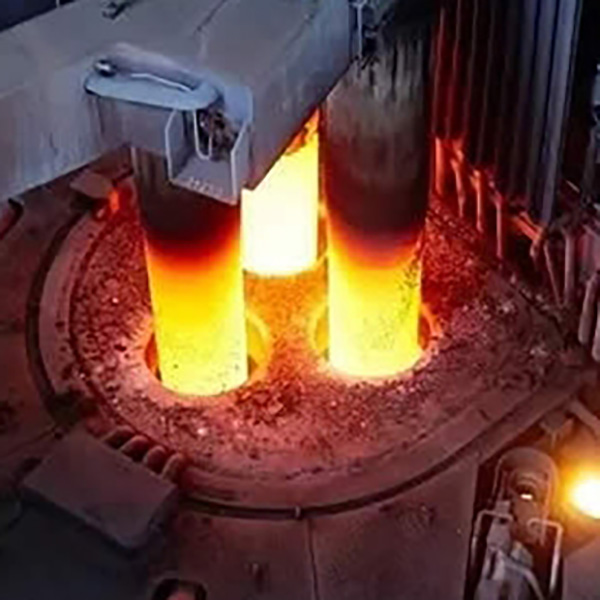

A graphite electrode is a high-performance consumable conductor that plays an indispensable role in electric arc furnace steelmaking. Think of it as the heating element in the world’s most powerful kettle. Its primary job is to conduct massive amounts of electrical power from a transformer into the furnace. When the electrode tips get close to the metal charge (primarily scrap steel), this huge electric current jumps the gap, creating a sustained and incredibly powerful electric arc. This arc is what generates the intense heat required to melt the solid metal. Without a reliable electrode, the entire electric arc furnace simply cannot function.

The choice of graphite is no accident. This material possesses a unique combination of properties that make it perfect for this extreme environment. First, it has excellent electrical conductivity, allowing it to handle the immense current density needed to form a stable arc. Second, it has superior thermal conductivity and an incredibly high melting point (sublimating at around 3,600 °C), allowing it to withstand the furnace’s heat. This combination of being a great conductor of both heat and electricity is rare. As a factory owner, I can attest that producing a consistent, high-quality graphite electrode is a complex process designed to maximize these natural advantages. The electrode is used to transfer this energy efficiently, making it the true workhorse of the melt shop.

How Does the Electric Arc Furnace (EAF) Process Work to Melt Steel?

The EAF steelmaking process is a marvel of modern recycling. It begins with the “charge,” where a massive bucket loads scrap steel into the furnace. Once charged, the roof swings back into place, and the three graphite electrodes are carefully lowered towards the scrap. This is a critical moment. The system applies a high voltage to the electrodes, and as they approach the metallic charge, a powerful electric arc ignites between the electrode tips and the steel. This is where the magic happens. The arc itself can reach temperatures hotter than the surface of the sun, instantly beginning to melt the scrap directly beneath it.

What Are the Different Grades of Graphite Electrodes (HP, UHP)?

Not all graphite electrodes are created equal. They are typically categorized into three main grades based on their properties and the type of furnace they are designed for: Regular Power (RP), High Power (HP), and Ultra-High Power (UHP). The primary difference lies in the quality of the raw material used and the resulting physical properties, such as electrical resistance and permissible current density. For a procurement professional, understanding these grades is crucial for matching the right electrode to the right application, ensuring both performance and cost-effectiveness.

UHP electrodes are the pinnacle of graphite electrode technology. They are made from premium-grade needle coke, a crystalline petroleum coke that gives the final product very low electrical resistance and excellent thermal shock resistance. This allows them to handle the extremely high currents required in modern, high-productivity UHP arc furnaces. HP, or hp graphite, electrodes are a step down, often made from a blend of needle coke and other high-quality petroleum coke. They are suitable for high-power electric furnace operations and some ladle furnace applications. RP electrodes are the most basic grade, designed for lower-power operations like smelting silicon or phosphorus.

Here is a simplified comparison:

| Property | Regular Power (RP) | High Power (HP) | Ultra-High Power (UHP) |

|---|---|---|---|

| Raw Material | Regular petroleum coke | Blend of quality petroleum coke | Premium needle coke |

| Current Density | Low (< 17 A/cm²) | Medium (18-25 A/cm²) | Very High (> 25 A/cm²) |

| Electrical Resistance | Higher | Lower | Lowest |

| Density | Lower | Higher | Highest |

| Application | Smelting, ferroalloys | HP EAFs, Ladle Furnaces | UHP EAFs |

Choosing a UHP electrode for a low-power furnace would be unnecessarily expensive, while using an RP electrode in a UHP furnace would lead to rapid consumption and likely breakage. For demanding applications, an Ultra-high power graphite electrode is not just a preference but a necessity for operational stability and efficiency.

What Key Quality Indicators Should a Procurement Officer Look For in a Graphite Electrode?

When I speak with customers like Mark, their primary concern is always quality. A low-quality electrode can break in the furnace, causing costly downtime and potentially damaging the equipment. So, what should you look for? First, examine the physical and electrical specifications. A high-quality graphite electrode should have a high bulk density and low apparent porosity. Higher density generally correlates with greater high mechanical strength and better resistance to oxidation. The most critical electrical property is low resistivity (or high electrical conductivity). A lower resistance means the electrode can carry the required current with less energy consumption and heat generation within the electrode itself.

Beyond the spec sheet, certification is non-negotiable. Always demand ISO 9001 certification for the manufacturing facility and detailed material test reports for each batch. These reports should verify properties like flexural strength, modulus of elasticity, and the coefficient of thermal expansion. A reputable supplier will have no issue providing this documentation. Another key factor is consistency. A good graphite electrode manufacturer ensures tight tolerances on dimensions and threading. Poorly machined threads can lead to loose joints, overheating, and eventual failure at the connection point. This is where I’ve seen some suppliers cut corners, so it’s a detail worth scrutinizing. The presence of any impurity can also drastically affect performance, making material purity a silent but vital quality marker.

How is a Graphite Electrode Manufactured to Withstand Extreme Temperatures?

The journey from a simple raw material to a finished graphite electrode is a long and energy-intensive process that explains its value. It all starts with high-quality petroleum coke, specifically needle coke for UHP grades. This coke is milled into a fine powder and mixed with coal tar pitch, which acts as a binder. This paste is then extruded or molded into a “green” electrode form. This green electrode is still soft and has no strength. The next step is baking. The electrodes are placed in a large furnace and slowly heated to around 800-1000 °C over several weeks. This process, called calcination or to calcine, burns off volatile materials and converts the pitch into solid carbon, creating a hard, carbonaceous block.

What Causes Graphite Electrode Consumption and How Can It Be Minimized?

Graphite electrode consumption is a significant operational cost in EAF steelmaking, so understanding its causes is vital. There are two primary mechanisms of consumption. The first is tip consumption, which is the sublimation of the carbon at the electrode tips due to the intense heat of the electric arc. This is an unavoidable part of the process, as this is how the electrode does its work to melt the steel. The second, and often more manageable, cause is sidewall oxidation. As the hot graphite electrode is exposed to air and furnace gases, the carbon on its surface reacts with oxygen and burns away, reducing the electrode‘s diameter. This process is highly dependent on furnace operating practices.

Minimizing consumption is a joint effort between the steelmakers and the electrode supplier. From the user’s side, several practices can help.

- Optimizing Arc Stability: A stable, long arc can reduce heat loss and focus energy more efficiently on the melt, but an overly long arc can increase radiation to the sidewalls, increasing refractory wear and oxidation. A short, stable arc is often ideal.

- Controlling Furnace Atmosphere: Minimizing air ingress into the furnace is critical. Sealing gaps and maintaining positive pressure can significantly reduce the amount of oxygen available to react with the electrode surface. Some operations inject argon to create an inert atmosphere.

- Water Cooling: Modern furnaces often use water cooling spray rings that create a protective curtain of steam around the electrode, reducing oxidation.

- Foamy Slag Practice: A good foamy slag practice can submerge the arc, shielding the electrode from the furnace atmosphere and reducing both thermal stress and oxidation.

From my perspective as a manufacturer, providing a high-density electrode with a protective anti-oxidation coating is our contribution to lowering overall consumption for our customers.

What is the Role of the Electrode in Controlling the Steelmaking Process?

The graphite electrode is more than just a heating element; it is a precision tool for controlling the entire steelmaking process. The furnace transformer provides the electrical power, but the electrodes deliver it. By precisely controlling the vertical position of each electrode, operators can adjust the length of the arc. A longer arc (higher voltage) transfers more radiant heat, which is useful early in the melt, while a shorter arc (lower voltage, higher current) bores into the scrap more effectively. This control over the power input is crucial for optimizing the melt cycle.

Furthermore, the electrode system directly influences the temperature and chemistry of the molten bath. The amount of energy delivered determines the melt rate and final tapping temperature. The stability of the three-phase arc ensures even heating and promotes the circulation of the molten pool, leading to better homogeneity. This control is also vital during the refining stage. By managing the arc and creating specific slagging conditions, operators can effectively remove impurities like phosphorus and sulfur from the steel, meeting the tight specifications required for different steel grades. The ability to maintain a constant current or adjust it as needed gives the furnace operator incredible flexibility to refine the steel.

Are There Alternatives to Graphite Electrodes in EAF Steelmaking?

This is a question I hear from time to time, especially when graphite prices fluctuate. The simple answer is that for modern, high-power electric arc furnaces, there are currently no commercially viable alternatives to the graphite electrode. The reason lies in graphite’s unparalleled combination of properties. No other material can offer the same level of electrical conductivity, strength at extreme temperatures, and thermal shock resistance in such a cost-effective manner.

There are other heating technologies, like induction furnaces, but they operate on a different principle and are generally used for smaller-scale operations or foundries, not for the bulk EAF steelmaking of hundreds of tons at a time. Research into alternative materials and technologies is ongoing, of course, but the challenges are immense. Finding a material that can withstand the brutal environment inside an electric arc furnace and efficiently conduct the megawatts of power needed to create a stable arc is an incredible materials science challenge. For the foreseeable future, the graphite electrode will remain the cornerstone of the steelmaking process in EAFs. Its fundamental role is secure.

How Are Graphite Electrodes Used in Other Applications, like a Ladle Furnace or for Silicon Production?

While their most prominent use is in EAFs, the utility of a graphite electrode extends to other high-temperature metallurgical processes. One major application is the ladle furnace (LF). After steel is tapped from the primary steelmaking furnace (like an EAF or a basic oxygen furnace), it is often sent to a ladle furnace for secondary refining. Here, a smaller set of graphite electrodes provides gentle heating via a submerged arc to precisely control the temperature, allowing for alloy additions and vacuum refining to achieve the final desired chemistry and quality. The demands on the electrode in a ladle furnace are less severe than in an EAF, so hp graphite electrodes are often sufficient.

Another significant user is the submerged arc furnace. These furnaces operate differently, with the electrode tips remaining buried, or submerged, in the raw material charge. The heat is generated through resistive heating as the current passes through the charge material itself. This process is used to smelt various materials and produce industrial commodities like silicon metal (a key component in aluminum alloys and electronics), ferroalloys (like ferrochrome and ferrosilicon), and calcium carbide. In these applications, the chemical purity of the electrode is as important as its electrical properties, as any impurity from the graphite electrode can transfer to the final product, whether it be silicon or phosphorus. Beyond large electrodes, the versatility of graphite is also seen in components like a High temperature resistant graphite crucible for melting for smaller, specialized tasks.

What Are the Best Practices for Handling and Connecting Graphite Electrodes?

A high-quality graphite electrode can be rendered useless by improper handling. This is a crucial area where procurement officers can add value by ensuring their teams or clients follow best practices, directly addressing the logistical concerns many, like Mark, face. Graphite is strong but brittle, and a drop or sharp impact can cause internal cracks that lead to failure under load. Electrodes should always be stored in a dry, clean area on wooden supports, never directly on the ground. When moving a graphite electrode, dedicated lifting plugs that screw into the socket should be used; never use a steel chain or sling directly around the electrode body.

The connection, or “jointing,” of one electrode to another is the most critical step. This is the point of highest mechanical and electrical stress.

- Cleanliness is Key: Both the socket of the used electrode in the furnace and the threads of the new electrode and connecting nipple must be blown completely clean with compressed air. Any debris can create a gap, causing an electrical hot spot.

- Proper Alignment: The new electrode must be perfectly aligned vertically before being lowered for connection. Misalignment will damage the threads.

- Torque is Everything: Use a calibrated torque wrench to tighten the joint to the manufacturer’s specified value. Under-tightening leads to a loose, hot joint. Over-tightening can fracture the electrode or nipple.

As a manufacturer, we provide these specifications, and I always stress to my clients that following them is the single most important thing they can do to ensure good electrode performance. It protects their investment and ensures the safety of their steelmakers. For many applications, other carbon components are just as vital, such as a High performance pre baked anode carbon block which requires similar careful handling.

Key Takeaways

To navigate the world of graphite electrodes successfully, here are the most important things to remember:

- Quality is Paramount: Look for high density, low electrical resistance, and high mechanical strength. Always insist on ISO certifications and detailed material test reports.

- Know Your Grades: Match the electrode grade (RP, HP, UHP) to the furnace’s power level and application. Using the right grade, like a proper hp graphite or UHP electrode, is essential for efficiency.

- Consumption is Controllable: While tip consumption from the arc is inevitable, sidewall oxidation can be minimized through good operating practices like maintaining a foamy slag and preventing air leaks.

- Handling Matters: A graphite electrode is a high-value, brittle consumable. Proper storage, handling with correct equipment, and meticulous jointing procedures are critical to prevent premature failure.

- Your Supplier is Your Partner: Communication is key. Work with suppliers who are transparent, knowledgeable, and willing to provide technical support. A good supplier helps you solve problems, not just sell you a product. For demanding furnaces, a partner who supplies materials like a High strength graphite block for linings and a premium graphite electrode for melting is invaluable.

Post time: 06-23-2025