As someone who has spent years in the graphite industry, overseeing production lines and speaking with procurement leaders like Mark Thompson from the USA, I’ve noticed a common thread. While everyone knows they need graphite electrodes, the full scope of their power and versatility is often underestimated. You might be buying them for your electric arc furnace, but do you know why they are the undisputed champion for that job? Or how the same basic material is used in precision Electrical Discharge Machining (EDM)? This article is for you. It’s a deep dive into the world of the graphite electrode, written from a manufacturer’s perspective. We’ll explore not just the "what," but the "why"—why this humble-looking carbon rod is a cornerstone of modern industry. Understanding these uses will empower you to make smarter purchasing decisions, ask the right questions, and truly appreciate the value packed into every electrode you source.

What Exactly is a Graphite Electrode and Why is it so Important?

At its core, a graphite electrode is a large, cylindrical column made from synthetic graphite. Think of it as a giant, super-powered pencil lead, but instead of writing, its job is to conduct immense amounts of electricity. Its importance stems from a unique combination of properties that are very difficult to find in any other material. First, it has incredibly high electrical conductivity. It allows electricity to flow through it with minimal resistance, which is crucial for delivering the power needed in industrial processes. Imagine trying to run a massive furnace through a tiny, inefficient wire—it just wouldn’t work. The graphite electrode is that superhighway for electrical power.

Second, it boasts remarkable thermal shock resistance and strength at high-temperature levels. While most materials would melt, crack, or deform under the intense heat of a furnace (we’re talking temperatures over 3,000°C or 5,400°F!), a graphite electrode actually gets stronger as it gets hotter, up to a certain point. This allows it to operate right in the heart of the action, inside a molten metal bath, without failing. This combination of being a great conductor of electricity and being able to withstand extreme heat makes the graphite electrode an indispensable tool in many industries, particularly in metallurgy and manufacturing. It’s the key that unlocks processes that would otherwise be impossible or wildly inefficient.

How do Graphite Electrodes Power the Iron and Steel Industry?

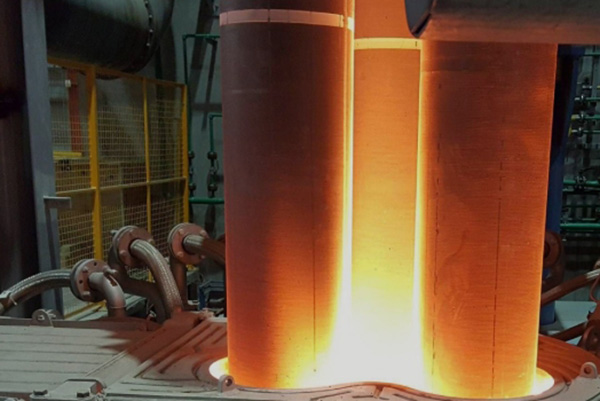

The iron and steel industry is, without a doubt, the largest consumer of graphite electrodes. The primary application is in Electric Arc Furnaces (EAFs), which have become a cornerstone of modern steel production, especially for recycling. In my experience exporting to steel mills across North America and Europe, the demand for reliable, high-quality graphite electrodes is constant because they are the heart of the EAF operation. The process is both brilliantly simple and incredibly powerful. Large graphite electrodes are positioned inside a furnace filled with raw materials, which is typically scrap steel.

An enormous electric current is passed through the electrode. This current then jumps from the tip of the electrode to the scrap metal, creating a sustained, high-energy electric arc. This is not a small spark; it’s a continuous bolt of lightning inside a closed container. The heat generated by this electric arc is so intense that it can melt tons of scrap steel in a relatively short amount of time. The molten steel can then be tested, have its chemical composition adjusted with an alloy or other elements, and be poured into a mold to create new steel products. This method is not only effective but also more environmentally friendly than traditional blast furnaces, as it primarily uses recycled steel.

What is the Critical Role of a Graphite Electrode in an Electric Arc Furnace?

Diving deeper into the electric arc furnace (EAF), the graphite electrode is more than just a heating element; it’s a consumable tool that performs a critical function. In an EAF, a set of three graphite electrodes is typically used. They act as the terminals that introduce electrical energy into the furnace. When the power is turned on, the heat generated by the electric arc between the electrode tips and the metal charge can reach temperatures high enough to melt Mount Everest if it were made of steel. The electrodes are mounted on arms that can raise and lower them into the furnace as the scrap melts down.

The graphite electrodes are consumed during this process through two main mechanisms: tip sublimation (turning directly from a solid to a gas due to the extreme heat) and oxidation of the side walls. This consumption, or electrode wear, is a significant operating cost for a steel mill, which is why procurement officers like Mark are always looking for a balance between price and quality. A lower-quality electrode might be cheaper upfront but will be consumed much faster, leading to more downtime and higher overall costs. The use of graphite is essential here because no other known material can provide the required electrical conductivity and withstand the brutal high-temperature environment inside an active EAF. The goal is always to efficiently melt the scrap and refine the molten steel with minimal electrode consumption.

Can a Graphite Electrode Be Used as an Anode in Other Processes?

Yes, absolutely. While the steel industry is its biggest market, graphite’s properties make it an excellent anode material in various electrochemical processes, primarily electrolysis. An anode is the positive electrode in an electrolytic cell, where oxidation occurs. For this to work, the anode must be conductive and, crucially, must not react with the chemicals in the solution. Graphite is often the perfect choice because it is chemically inert in many environments.

A classic example is the production of aluminum. In the Hall-Héroult process, large carbon or graphite blocks are used as the anode to pass a current through a molten bath of cryolite and alumina. The process breaks down the alumina, producing pure aluminum metal. Another rapidly growing area is in lithium-ion batteries. The anode in nearly every lithium-ion battery, from your smartphone to an electric vehicle, is graphite-based. During charging, lithium ions are stored between the layers of the graphite’s molecular structure. When you use the battery, the ions move out of the anode and through the electrolyte to the cathode, generating the electric current. The ability of graphite to host and release the lithium ion efficiently is fundamental to the charge and discharge cycle and the high energy density of these batteries.

What is Electrical Discharge Machining (EDM) and Why Use Graphite Electrodes for it?

Electrical Discharge Machining, or EDM, is a high-precision manufacturing process that might seem like science fiction. Instead of cutting metal with a physical tool, EDM uses controlled electrical sparks to erode it. Here’s how it works: an electrode (the tool) is brought very close to a workpiece, both submerged in a dielectric fluid. A powerful electrical voltage is applied, creating a spark that jumps from the electrode to the workpiece, vaporizing a tiny amount of the metal. This happens thousands of times per second, slowly and precisely removing material to create a desired shape or mold, often with incredibly complex details that would be impossible to achieve with traditional machining.

So, why are graphite electrodes in EDM so popular? For several reasons. First, graphite is much easier to machine than metals like copper, meaning you can create the electrode tool in very intricate shapes quickly and cheaply. Second, graphite electrodes have a very low wear and tear rate in the EDM process. This means the electrode maintains its shape longer, leading to more accurate final parts. Finally, graphite can handle higher currents than copper, which allows for faster material removal rates, speeding up the entire discharge machining process. For companies in the automotive or aerospace industries that need to produce complex injection molds or parts, using graphite electrodes for electrical discharge machining is a game-changer for efficiency and precision.

How do I Choose the Right Type of Graphite Electrode for My Application?

This is a question I discuss with customers like Mark frequently. Not all graphite electrodes are created equal, and choosing the right one is critical for both performance and cost-effectiveness. The choice primarily depends on the intensity of the application. They are generally categorized into three grades:

- Regular Power (RP): These are used in smaller, lower-power furnaces, often for smelting non-ferrous metals or producing silicon. They are made from standard-grade petroleum coke.

- High Power (HP): These are designed for higher-power electric arc furnaces, typically used in foundries or for some steel recycling operations. They use a better grade of petroleum coke and have better thermal and mechanical properties than RP electrodes.

- Ultra-High Power (UHP): These are the top-tier electrodes, designed for the most demanding, high-current electric arc furnaces used in modern steel mills. They are made from premium needle coke, which gives them extremely low electrical resistance and superior resistance to thermal shock. A High-power graphite electrode is a workhorse, but for the most intense EAFs, an ultra-high power graphite electrode is necessary to handle the load without excessive wear.

Here’s a simplified table to help guide your decision:

| Electrode Grade | Primary Raw Material | Key Application | Furnace Type |

|---|---|---|---|

| RP (Regular Power) | Standard Petroleum Coke | Smelting non-ferrous metals | Low-power furnace |

| HP (High Power) | High-quality Petroleum Coke | Foundry & Steel recycling | High-power EAF / Ladle Furnace |

| UHP (Ultra-High Power) | Premium Needle Coke | High-volume steel production | Ultra-high power EAF |

Choosing a UHP electrode for a low-power furnace would be needlessly expensive. Conversely, using an RP electrode in a UHP furnace would be disastrous; it would break and be consumed almost instantly. Matching the electrode to the furnace and process is key to an efficient and stable operation.

Beyond Steel and EDM: What are the Other Surprising Uses of Graphite?

While steel and EDM are the titans of graphite electrode uses, this versatile carbon material has many other important applications. Its stability at high temperature and chemical stability make it an excellent refractory material. This means it’s used to make bricks and linings for furnaces and kilns to protect the outer shell from the intense heat inside. It’s also used to make a crucible—a container used to hold and melt metals like gold, silver, brass, and aluminum in foundries. A high temperature resistant graphite crucible for melting is essential because it won’t react with or contaminate the molten metal.

In the world of advanced materials, graphite is used to create other compounds. For example, by heating sand (silicon dioxide) and carbon (often from petroleum coke) in a graphite electrode furnace, we can produce silicon carbide, an extremely hard ceramic used in abrasives, car brakes, and even bulletproof vests. Furthermore, in the nuclear industry, certain types of reactors, like high-temperature gas-cooled reactors (HTGRs), use large blocks of graphite as a moderator. The graphite slows down the neutrons produced during fission, allowing the nuclear chain reaction to be sustained and controlled. It also provides structural integrity within the reactor core at extreme temperatures, a job few other materials could handle.

How is a High-Quality Graphite Electrode Made?

As a manufacturer, I can tell you that creating a high-quality graphite electrode is a long and complex process that demands precision at every step. It’s a journey of transforming simple raw materials into a high-performance industrial tool. It begins with carefully selected carbonaceous materials like needle coke (for UHP electrodes) or petroleum coke. This coke is first crushed and sized, then mixed with coal tar pitch, which acts as a binder.

This paste-like mixture is then extruded or pressed into the shape of a green electrode. This "green" electrode is still soft and has none of the properties we need. It then goes through a series of crucial heating steps:

- Baking: The green electrode is slowly baked in a furnace for several weeks at around 800°C. This process, known as calcine-ing, burns off volatile materials and solidifies the binder, creating a hard carbon block.

- Impregnation: The baked electrode is porous. To increase its density and strength, it is placed in a vacuum chamber and impregnated with more pitch. This step is often repeated to ensure maximum density.

- Re-baking: The impregnated electrode is baked a second time to convert the new pitch into carbon.

- Graphitization: This is the final and most critical step. The electrode is heated in a special furnace to an incredibly high temperature of nearly 3,000°C. This intense heat rearranges the carbon atoms from a random, amorphous structure into the ordered, layered crystalline structure of synthetic graphite. This step is what gives the electrode its fantastic electrical conductivity and thermal resistance.

Finally, the now-finished graphite electrode is precisely machined to have smooth surfaces and threaded sockets so it can be connected to other electrodes to form a continuous column in the furnace.

What Should a Procurement Officer Look for When Sourcing a Graphite Electrode?

For a procurement officer like Mark, sourcing a graphite electrode is a high-stakes decision. A bad batch can halt production at a steel mill, costing a company hundreds of thousands of dollars per day. Having been on the other side of these conversations for years, I advise focusing on these key areas to avoid common pain points:

- Verified Quality and Certifications: Don’t just accept a certificate at face value. Ask for detailed test reports for the specific batch you are buying, showing data for electrical resistivity, bulk density, and flexural strength. Ask about their quality control process. A reputable factory will be transparent and welcome these questions. Certificate fraud is real, so diligence is paramount.

- Technical Communication: Your sales contact should be more than just a salesperson. They should have a solid understanding of the product. If they can’t answer basic technical questions about the difference between HP and UHP electrode performance or why needle coke matters, it’s a red flag. Inefficient communication is a major pain point and often signals deeper organizational issues.

- Logistics and Reliability: Shipment delays can be disastrous. Discuss logistics clearly from the start. Understand the production lead time, the shipping route, and the customs clearance process. A reliable supplier will have a proven track record and can provide references or case studies of successful deliveries to your region, be it the USA, Europe, or Australia.

- Supplier’s Identity and Expertise: Are you buying from a trader or directly from a factory? As a factory owner, I know the level of control we have over quality is immense. A trader may not have the same level of technical expertise or control. Visiting the factory, either in person or through a detailed virtual tour, can provide immense confidence. Seeing the production lines and meeting the team can tell you more than any brochure. For example, a reliable supplier should be able to offer a range of products, from an Extra Large Graphite Electrode to various graphite blocks and powders.

The Future of Graphite: What’s Next for This Critical Carbon Material?

The future for the graphite electrode and graphite-based materials looks incredibly bright. Several global trends are driving demand. The biggest is the global push towards a circular economy and greener steel production. As more countries focus on recycling, the use of electric arc furnace technology will continue to grow, directly increasing the demand for UHP graphite electrodes. The EAF process produces significantly less CO2 per ton of steel compared to traditional blast furnaces that use metallurgical coke and pig iron, making it a key technology for decarbonizing the industry.

Simultaneously, the electric vehicle revolution is a massive driver for graphite. As mentioned, graphite is the dominant anode material in lithium-ion batteries, and the demand is skyrocketing. This has created two competing markets for high-quality needle coke, pushing innovation in both the electrode and battery industries. We’re also seeing new research into advanced graphite-based products, such as graphene and specialty composites, for use in aerospace, electronics, and energy storage. The unique properties that make graphite essential today will ensure its place as a critical carbon material for decades to come.

Key Takeaways

To summarize, here are the most important things to remember about the graphite electrode:

- Core Function: Its primary job is to conduct massive amounts of electricity into a furnace to melt materials, mainly in the steel industry.

- Key Properties: It is valued for its extremely high electrical and thermal conductivity, coupled with incredible strength and stability at very high-temperature levels.

- EAF is King: The main use of graphite electrodes is in Electric Arc Furnaces (EAFs) for melting scrap steel, a process that is both efficient and more environmentally friendly than traditional methods.

- Precision in EDM: In Electrical Discharge Machining (EDM), graphite electrodes are used to precisely erode metal with sparks, creating complex molds and parts with high accuracy and low electrode wear.

- Versatile Anode: Graphite’s conductive and inert nature makes it an ideal anode material in electrolysis for producing metals like aluminum and, most notably, in the lithium-ion batteries that power our modern world.

- Choose Wisely: Graphite electrodes come in different grades (RP, HP, UHP). Selecting the correct grade for your furnace‘s power level is crucial for optimizing performance and cost.

- Quality is Paramount: When sourcing, look beyond the price. Focus on verified quality reports, technical expertise from your supplier, and reliable logistics to avoid costly production disruptions.

Post time: 07-16-2025