For any procurement officer navigating the steel industry or metallurgy sectors, few things are as headache-inducing as the fluctuating costs of essential consumables. One month, the market is stable; the next, supply chain disruptions or raw material shortages send costs skyrocketing. At the center of this financial balancing act is the graphite electrode. Whether you are running massive electric arc furnaces (EAF) to melt scrap steel or sourcing specialized carbon components for precision casting, understanding the dynamics behind graphite electrode prices is essential for maintaining a healthy bottom line. It is not just about finding the cheapest option; it is about understanding value, longevity, and the hidden factors that drive the current price on the global market.

What Drives the Fluctuation in Graphite Electrode Prices?

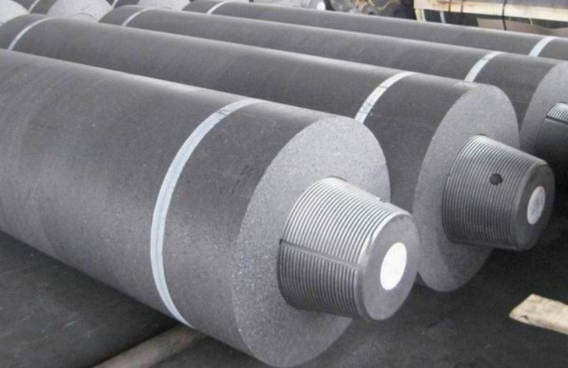

To the untrained eye, a graphite electrode is just a large black cylinder. However, the economics behind its pricing are complex and multifaceted. The price of graphite electrodes is rarely static. It is heavily influenced by the global demand for graphite electrodes, particularly from the steel sector, which consumes the vast majority of these products.

When steelmaking output increases, particularly in countries utilizing EAF technology, the demand for electric arc furnace consumables spikes. If this surge coincides with a shortage of raw material, prices can double or triple in a short period. Furthermore, market trends regarding environmental regulations play a massive role. Stricter environmental policies in producing countries can limit the operation of graphitization furnaces, constricting supply and driving up the electrode price.

For buyers, analyzing the trend is crucial. Are we in a surplus or a deficit? Currently, the industry is seeing a stabilization, but regional conflicts and logistics costs continue to add layers of unpredictability to graphite electrode prices.

The Role of Raw Materials: Needle Coke and Petroleum

If you want to understand the pricing of high-grade electrodes, you have to look at what they are made of. The primary raw material for high-quality electrodes is needle coke. This is a premium grade of petroleum coke with a needle-like structure, essential for handling high temperatures and electrical stress.

Needle coke is derived from petroleum or coal tar pitch. The catch? It is also a key component in the battery industry, specifically for lithium-ion batteries used in electric vehicles. As the EV market explodes, the competition for needle coke intensifies. This tug-of-war between the steelmaking industry and the battery sector puts upward pressure on raw material costs.

Consequently, the price of graphite electrodes, especially the UHP graphite electrode (Ultra-High Power) used in demanding applications, is directly tethered to the availability and cost of premium needle coke. Lower-grade electrodes might use regular petroleum coke or anthracite, which keeps their price lower, but they cannot perform in high-intensity electric arc environments.

UHP vs. HP vs. RP: How Grade Affects the Electrode Price

Not all electrodes are created equal. In the metallurgy world, we generally categorize them into three main grades: Regular Power (RP), High Power (HP), and Ultra-High Power (UHP). The pricing distinctness between these grades is significant.

- RP Graphite: Made mostly from petroleum coke and coal tar pitch. Used in smaller furnaces. These have the lowest current price point.

- HP Graphite: Contains a blend of needle coke (around 30%) and high-quality petroleum coke.

- UHP Graphite: Composed almost entirely of premium needle coke.

A UHP graphite electrode commands the highest price because it offers superior electrical conductivity and thermal shock resistance. In a massive electric arc furnace where temperatures reach thousands of degrees, a UHP electrode consumes slower and breaks less often. While the upfront electrode price is higher, the "cost in use" (cost per ton of steel produced) can actually be lower because you use fewer electrodes. Conversely, using a cheap RP electrode in a high-powered furnace is false economy; it will likely break or oxidize rapidly.

From Steel to Science: Industrial Applications vs. Scientific Experiments

While my business focuses on the heavy industrial side—supplying tons of electrodes to steel mills—there is a fascinating micro-market for graphite. If you search online, you will find terms like "carbon for scientific experiments electroplating" or "scientific experiments electroplating plating" kits.

In these contexts, buyers aren’t looking for tons; they are looking for a rod cylinder stick carbon rod or a graphite stirring rod cylinder stick. Brands like Stonylab graphite or Meccanixity graphite often appear in these searches, catering to laboratories or hobbyists. These small-scale items, often sold as a piece metal electrodes set electrode or electrodes set electrode strips set, have a wildly different pricing structure per gram compared to industrial graphite electrode prices.

In a lab, a graphite rod might be used for electrolysis demonstrations or as a conductive anode in a small beaker. In these scenarios, the purity graphite electrode requirements might be different, focusing on chemical inertness rather than thermal shock resistance. It highlights the versatility of carbon: indispensable whether you are melting 100 tons of scrap or conducting a high-school chemistry experiment.

High Purity Graphite Electrode and Specialized Forms

Moving back to the industrial scale, purity is a major determinant of value. A high purity graphite electrode typically implies a carbon content of 99.95% or higher, with very low ash content. Impurities like iron, silicon, or sulfur can contaminate the melt or cause the electrode to degrade faster.

Specialized forms also affect pricing. Beyond the standard large cylinders, we see demand for:

- Graphite Sheet Electrode: Used in fuel cells or heat dissipation.

- Graphite Rods: Used in EDM (Electrical Discharge Machining) or as heating elements.

- Crucible: A crucible made of graphite is essential for melting casting non-ferrous metals like gold or silver.

- Furnace Carbon: Structural blocks used to line furnaces.

The machining required to produce a specific graphite sheet electrode or a precision rod with a 6 mm diameter and 90 mm length adds to the cost. The more processing (machining, purification, coating) required, the higher the price tag.

The Impact of Manufacturing Complexity on Pricing

Why does it take months to fulfill an order? The manufacture of a high-quality graphite electrode is an incredibly slow and energy-intensive process. It involves crushing, screening, mixing, forming, baking, impregnating, re-baking, graphitizing, and machining.

The graphitization step alone—where the baked carbon is transformed into graphite carbon by heating it to over 3000°C—takes weeks. This process aligns the carbon atoms, giving the material its unique thermal and conductive properties. This step consumes a massive amount of electric power. Therefore, energy prices in the manufacturing country directly impact the competitive graphite electrode prices a supplier can offer. When energy costs rise, the cost to produce furnace carbon rises with it.

Furthermore, precision is key. A metal electrodes set electrode strips for a battery test needs different specs than a 600mm UHP electrode, but both require strict quality control. The risk of breakage during graphitization is real, and yield rates affect the final cost passed on to the buyer.

Finding Competitive Graphite Electrode Prices for Export

For a buyer like Mark in the USA, sourcing from a manufacturer in China is often the best way to secure competitive graphite electrode prices. China is a dominant player in the global export of carbon products. However, the "sticker price" is only one part of the equation.

When evaluating an export quote, you must consider:

- Logistics: Shipping heavy, fragile graphite rods across the ocean requires secure crating and careful handling.

- Tariffs: Trade policies can add a significant percentage to the landed cost.

- Payment Terms: Favorable terms can offset a slightly higher unit price.

- Consistency: Does the supplier deliver the same high-power graphite electrode quality every shipment?

Finding a direct factory eliminates the middleman markup. Traders often rebrand hp graphite or rp graphite, adding their margin. Dealing with the source ensures you are paying for the product, not the brokerage.

Small Scale: Graphite Stirring Rod Cylinder Stick and Metal Electrodes Set

Let’s touch briefly on the terminology that often confuses buyers. Sometimes, a request comes in for a stirring rod cylinder stick carbon or a black for electrode component. These are often distinct from the massive EAF electrodes.

A graphite stirring rod cylinder stick is chemically inert and non-stick, making it perfect for mixing molten metals or reactive chemicals in industrial applications. Similarly, a metal electrodes set electrode strips might refer to the small carbon plates used in electroplating baths. Even though these are small, they utilize pure graphite. The price per kilogram for these small, precision-machined items is significantly higher than bulk electrodes due to the labor involved in shaping a rod cylinder stick carbon rod to exact tolerances (like the 6 mm diameter mentioned earlier).

If you are in the melting casting business for jewelry or small parts, you might use a meccanixity graphite crucible or rod. While these consumer-facing brands are convenient for single items, for bulk industrial applications, sourcing custom-machined graphite rods from a B2B factory is far more economical.

Future Market Trends and Demand for Graphite Electrodes

Looking ahead, the trend for graphite electrode demand is upward. As the world moves toward "green steel," the shift from Blast Furnaces (which use coal) to Electric Arc Furnaces (which use electricity and scrap) is accelerating. This means the metal industry will need more electrodes.

Simultaneously, the aluminum sector relies on carbon anodes and cathodes for electrolysis. The aluminum smelting process is chemically distinct but relies on the same upstream carbon supply chain.

We also see growth in EDM (Electrical Discharge Machining), where uhp graphite is used to machine hard metals. The finer the grain of the graphite, the better the finish. As aerospace and medical industries require more complex metal parts, the demand for high purity EDM graphite grows.

However, the supply of needle coke remains the bottleneck. Until synthetic needle coke production scales up, uhp graphite electrode prices will likely remain robust.

Ensuring Quality in Your Carbon Sourcing

Whether you are buying a graphite electrode for a 100-ton furnace or a graphite rod for a casting project, quality verification is non-negotiable. A low price is attractive, but if the electrode breaks mid-melt, the downtime costs dwarf the savings.

Key quality indicators to check on your datasheet:

- Bulk Density: Higher is generally better for strength.

- Electrical Resistivity: Lower means better conductivity.

- Flexural Strength: Resistance to snapping.

- Ash Content: Should be very low (0.05% – 0.2% depending on grade).

Always ask your supplier for a certificate of analysis. If you are buying a uhp graphite product, ensure the specifications match international standards.

Summary

Navigating the landscape of graphite electrode prices requires a blend of market intelligence and technical knowledge.

- Market Drivers: Prices are driven by needle coke availability, steelmaking demand, and energy costs.

- Grades Matter: UHP graphite electrodes cost more due to premium raw materials but offer better efficiency in high-power furnaces compared to RP graphite.

- Diverse Applications: From massive furnace carbon to a tiny stirring rod cylinder stick carbon, the scale determines the unit economics.

- Manufacturing Lag: The months-long production cycle means prices react slowly to immediate demand changes.

- Sourcing: Partnering directly with a factory is the key to securing competitive graphite electrode prices and ensuring consistent export quality.

- Purity: For specialized uses like EDM or scientific experiments electroplating plating, high purity (99.95%) is essential.

By understanding these factors, you can make informed purchasing decisions, ensuring your operations—whether melting casting or mass steel production—run smoothly and profitably.

Post time: 01-14-2026