From the smartphone in your pocket to the powerful industrial machinery that builds our world, countless devices rely on a humble yet extraordinary material: carbon. Specifically, the unique form of carbon known as graphite is a hidden hero in modern technology. For procurement professionals like my friend Mark Thompson in the USA, who sources components for industrial clients, understanding the diverse applications of carbon and graphite is key to making informed purchasing decisions. This article will take you on a journey, exploring why this simple element is the cornerstone of so many technologies, with a special focus on its critical role as a carbon brush in electric motors. We will uncover the science, explore the applications, and provide insights that will help you source the best graphite products for any requirement.

What Makes Graphite So Special as an Industrial Material?

At its core, graphite is a special form of carbon. What makes it different from other forms, like diamond, is its atomic structure. Graphite atoms are arranged in layers, like a deck of cards. These layers can slide over one another easily, which gives graphite its signature softness and lubricating properties. But that’s just the beginning. This layered structure also allows electrons to move freely within each layer, making graphite an excellent conductor of electricity. This unique combination of properties is rare in nature.

Most materials are either conductive (like metal) or they are good lubricants, but rarely both. Graphite, however, excels in multiple areas. It can withstand incredibly high temperatures without melting, making it a fantastic refractory material. It is also lightweight and chemically stable, resisting corrosion and chemical attack. This versatility is why carbon and graphite are indispensable in so many industries. From the intense heat of a steel furnace to the delicate inner workings of electronics, graphite provides solutions where other materials would fail. Its unique properties make it the perfect material for a wide range of demanding application scenarios.

How Does a Carbon Brush Work Inside an Electric Motor?

Have you ever wondered how electrical energy gets to the spinning parts of an electric motor? The answer, in many cases, is the carbon brush. A carbon brush is a small block of specially engineered graphite or carbon graphite that is held in place by a spring, pressing it against a rotating part of the motor called the commutator. Its job is simple but critical: to conduct electricity from a stationary power source to the moving components of the motor or generator.

As the motor runs, the carbon brush maintains constant physical contact with the spinning commutator. This allows for the uninterrupted transfer of electrical current, which creates the magnetic fields that make the motor rotate. The reason a carbon brush is used instead of a simple piece of metal is due to graphite’s unique blend of properties. It is conductive enough to carry the current, yet soft enough that it wears down slowly over time instead of damaging the much more expensive commutator. This self-lubricating nature minimizes friction and wear, ensuring the motor runs smoothly for thousands of hours. Essentially, the carbon brush is a sacrificial component designed to be the point of wear, easy to replace when needed.

Why is the Connection to the Commutator So Important?

The interaction between the carbon brush and the commutator is the heart of a brushed DC motor. The commutator is a segmented ring made of a hard-wearing metal like copper. Each segment is connected to a different coil winding inside the motor’s rotor. As the rotor spins, the stationary carbon brush slides over these segments, delivering power to each coil in a precise sequence. This switching action is what keeps the rotor turning in one direction.

The reliability of this connection is everything. If the contact is poor, it can lead to sparking, power loss, and inefficient motor performance. This is why the design of the carbon brush is so important. The graphite material must have the right balance of conductivity and resistance to prevent overheating and excessive electrical arcing. Over time, the carbon brush will wear down due to the constant sliding contact, conforming perfectly to the surface of the commutator. A well-designed carbon brush ensures a stable, low-resistance path for electricity, maximizing the power and lifespan of the motor. This makes them essential in everything from a simple household appliance to heavy industrial machinery.

What Are the Different Types of Graphite Used for Brushes?

Not all electric motors are the same, so the carbon brush used inside them must be tailored to the specific application. The performance requirement of the motor—such as its speed, voltage, and load—determines the best type of carbon or graphite to use. There are several major categories of carbon brush materials, each with distinct properties.

| Brush Grade | Composition | Key Properties & Applications |

|---|---|---|

| Electrographite | Amorphous carbon processed at very high temperature | High strength, can handle high currents. Suitable for large DC motors and generators. |

| Carbon-Graphite | A mix of carbon and natural graphite | Good cleaning action on the commutator, durable. Used in fractional horsepower motors. |

| Graphite | Primarily composed of natural graphite | Low friction, quiet operation, limited current capacity. Used for high speed, low-current motors. |

| Metal-Graphite | Graphite mixed with fine metal powders (e.g., copper) | Very low electrical resistance, can handle very high currents. Used in low-voltage, high-current applications like forklift motors. |

As a manufacturer, we understand these nuances. The manufacturing process for an electro graphite brush is very different from that of a metal-graphite brush. The choice of raw materials and the processing techniques are carefully controlled to produce a carbon brush with the perfect balance of conductivity, hardness, and durability for its intended use. This ensures optimal performance whether the motor is in a power tool or an automotive starter.

Why is Graphite a Key Component in a Modern Battery?

The role of carbon and graphite extends far beyond electric motors. In fact, graphite is a critical, irreplaceable material in the production of one of today’s most important technologies: the lithium-ion battery. These are the batteries that power our laptops, phones, and increasingly, our cars. In a lithium-ion battery, graphite serves as the anode, which is the negative electrode.

During charging, lithium ions from the cathode travel through the electrolyte and are stored between the layers of the graphite anode. When you use your device, these ions travel back to the cathode, releasing the stored energy that powers your device. Graphite is the ideal anode material because its layered structure can hold a large number of lithium ions, which translates to a higher battery capacity. It is also stable, lightweight, and can endure many charge-discharge cycles. The demand for high-purity, high-performance graphite for lithium-ion batteries continues to increase as the world shifts towards portable electronics and electric cars.

How Can a Solid Material Like Graphite Act as a Lubricant?

It might seem strange that a solid black rock can be a lubricant, but graphite is one of the best dry lubricants available. This remarkable ability comes directly from its atomic structure. As we mentioned, graphite is made of stacked layers of carbon atoms. The bonds holding the atoms together within a layer are incredibly strong, but the forces holding the different layers together are very weak.

This means the layers can easily slide past one another with minimal force. When you apply graphite powder to a surface, you are depositing millions of these microscopic layers. They fill in imperfections and create a slippery surface that dramatically reduces friction between moving parts. Unlike oil-based lubricants, graphite can withstand extremely high temperatures and pressures. It is often used in applications like heavy machinery, locks, and forging processes where liquid lubricants would burn off or break down. This property is also why a graphite carbon brush works so well—it lubricates its own path along the commutator.

What Makes Carbon and Graphite a Superior Refractory Material?

A refractory material is one that can withstand extreme heat, pressure, and chemical attack without degrading. Graphite is one of the most effective refractory materials known. Its melting point is extraordinarily high, over 3,600°C (6,500°F), meaning it can handle temperatures found in steel manufacturing, foundries, and other metallurgical processes. When sourcing for my clients in these industries, the reliability of refractory components is a top priority.

Carbon and graphite are used to make crucibles for melting metal, linings for furnaces, and molds for casting. For example, our high temperature resistant graphite crucible for melting is designed specifically for these conditions. Beyond just heat resistance, graphite has excellent thermal shock resistance. This means it can handle rapid changes in temperature without cracking, a common point of failure for many ceramic materials. Its chemical inertness also prevents it from reacting with the molten metals or corrosive gases it contains, ensuring the purity of the final product. This makes graphite a cornerstone of high-temperature industrial processes.

What is the Role of Graphite in Advanced Composite Materials?

The applications for graphite are constantly evolving with technology. One of the most exciting areas is in composite materials. A composite is a material made by combining two or more different materials to create a new one with enhanced properties. When graphite fibers are combined with a polymer resin, they create a carbon fiber reinforced polymer (CFRP). This composite material is incredibly strong, stiff, and lightweight.

You’ll find CFRPs used in high-performance applications where weight is a critical factor, such as in the aerospace industry for aircraft components, in high-end automotive parts for racing and supercars, and in premium sporting goods like bicycle frames and tennis rackets. The graphite provides the strength and stiffness, while the polymer matrix holds it all together. The ability to create a material that is stronger than steel but a fraction of the weight has revolutionized engineering and design, all thanks to the humble carbon atom.

How is the Shape of a Graphite Component Manufactured?

Graphite rarely comes out of the ground in the exact shape needed for a carbon brush or a crucible. The raw carbon materials must undergo a complex manufacturing process to be turned into useful graphite products. It begins with mixing raw materials like petroleum coke and pitch, which are then molded or extruded into a basic form, often a large block or cylinder. This "green" component is then baked at high temperatures in a furnace without oxygen to convert the pitch into solid carbon, binding the particles together.

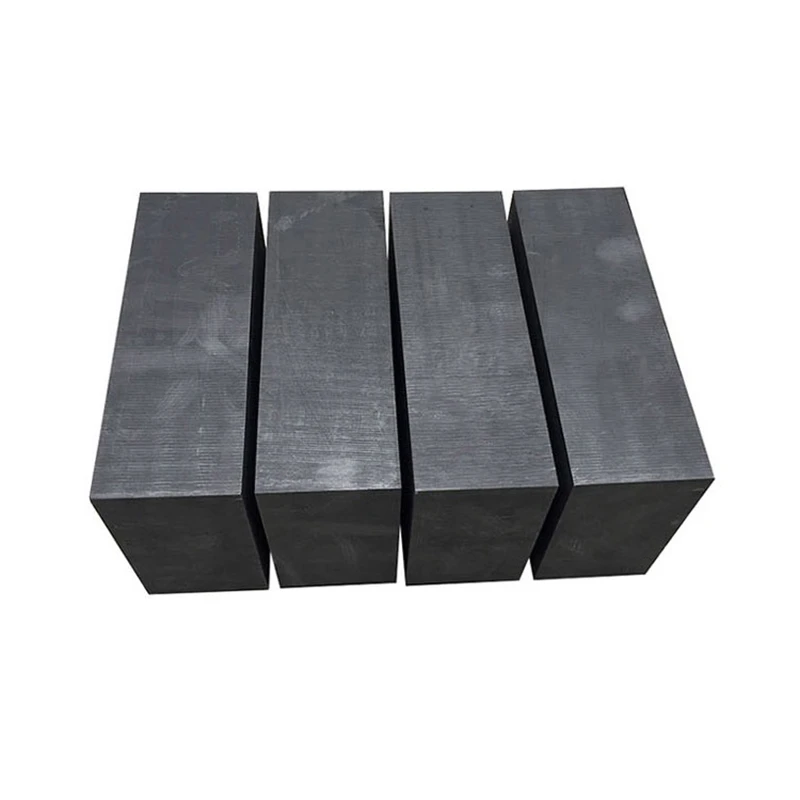

For many high-grade graphite types, like the ones used in our high strength graphite blocks, a final step called graphitization is required. This involves heating the material to even higher temperatures (up to 3,000°C), which rearranges the carbon atoms into the ordered, layered structure of graphite. After this, the solid graphite block can be precisely machined into any desired shape, whether it’s a tiny carbon brush or a large, complex electrode. This ability to machine graphite easily allows us to produce custom components that meet the exact specifications of any application.

What Should You Look For in a Graphite Supplier?

For a procurement professional, finding a reliable supplier for carbon and graphite components is crucial. The quality of these parts can directly impact your machinery’s performance, safety, and operational costs. The first step is to ensure the supplier is a genuine manufacturer, not just a trading company. A factory has direct control over the quality of the raw materials and the entire production process.

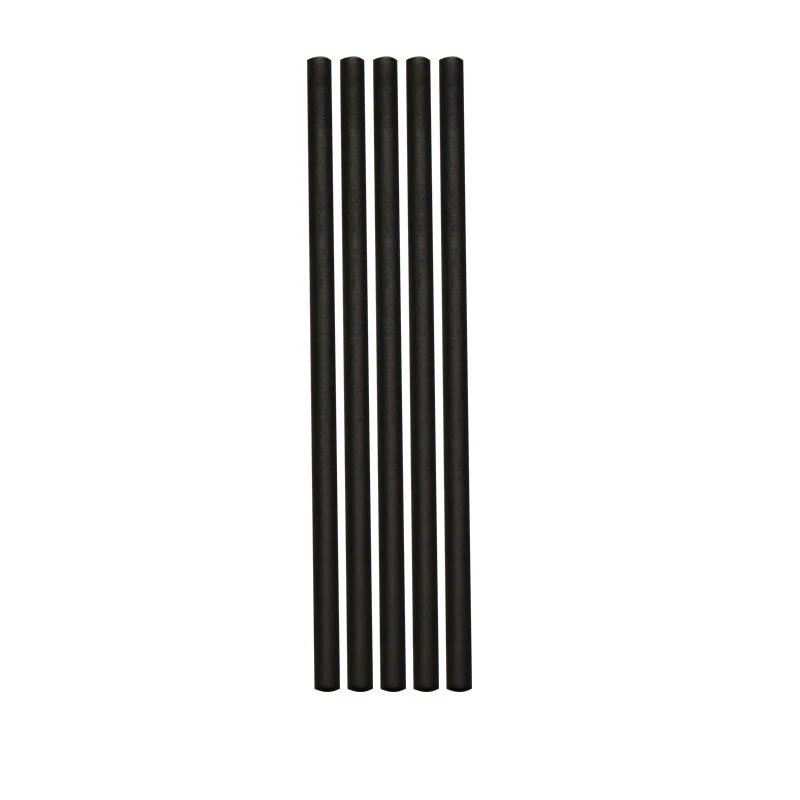

Always ask for detailed technical specifications and quality certifications like ISO 9001. A reputable supplier will be transparent and able to provide documentation to back up their claims. Communication is also key. You need a partner who understands your technical needs and can provide clear, timely updates on your order. Look for a company with experience exporting to your region, as they will be familiar with the logistics and standards required. Whether you need a standard carbon brush or a custom-machined component like a conductive graphite rod for electrodes, a strong supplier relationship built on trust and proven quality is your best asset.

Key Takeaways

The world of carbon and graphite is vast and full of innovation. From enabling the rotation of an electric motor to storing energy in a battery, its impact is undeniable. Here are the essential points to remember:

- Unique Properties: Graphite‘s layered atomic structure gives it a rare combination of electrical conductivity, high-temperature resistance, and self-lubricating properties.

- The Heart of the Motor: The carbon brush is a critical component that safely transfers electricity to the moving parts of a motor, acting as a sacrificial part to protect the more expensive commutator.

- Battery Anode: Graphite is the essential anode material in lithium-ion batteries, enabling the storage and release of energy that powers our modern world.

- Versatile Applications: Beyond motors and batteries, graphite is a vital refractory material for high-heat industries, a dry lubricant, and a key ingredient in strong, lightweight composite materials.

- Sourcing Matters: The quality of a graphite component depends on the manufacturing process. Partnering with an experienced and certified factory is the best way to ensure you receive reliable, high-performance products.

Post time: 09-09-2025