Graphite. For those of us in the industry, the word brings to mind a material of incredible contrasts. As Allen, the owner of a factory that has been shipping graphite products to the world for years, I’ve had countless conversations with business owners like Mark Thompson in the USA about the challenges and rewards of working with graphite. It’s a cornerstone of modern industry, vital for everything from steelmaking to aerospace, yet it demands respect. Machining graphite is not like cutting steel or aluminum; it’s a unique craft that requires specialized knowledge, tools, and techniques.

This comprehensive machining guide is born from years of hands-on experience. We will demystify the process, transforming it from a daunting task into a manageable one. Whether you are sourcing finished graphite components or planning to bring the machining processes in-house, this article will provide you with the essential insights for achieving precision and efficiency. We will explore everything from understanding graphite‘s peculiar nature to mastering the techniques that deliver flawless results.

First, What is Graphite and How is it Made?

Before you can machine graphite, you must understand what it is. At its core, graphite is a crystalline form of carbon, just like a diamond. But instead of a rigid, interlocking structure, its atoms are arranged in layers that can easily slide over one another, which is what gives graphite its characteristic softness and lubricity. Graphite is made in two primary ways: it’s either mined as natural graphite or created through a highly controlled industrial process to make synthetic graphite.

Most high-performance graphite is utilized in industries like aerospace and electrode production is synthetic. The synthetic graphite production process is fascinating. It starts with a carefully selected raw material, typically high-purity petroleum coke and coal tar pitch. These materials are mixed, molded, and then baked at a low temperature for weeks to create a dense, hard carbon block. The final, magical step is graphitization. The block is heated to an incredible high temperature—nearly 3000°C (5400°F)—which forces the carbon atoms to align into the perfect layered structure of graphite. This process gives us a material with exceptional purity and consistent, predictable properties, which are essential for high-precision machining.

Understanding Graphite: Why Are Its Unique Properties a Double-Edged Sword?

The advantages of graphite are numerous, which is why it is so widely used. Its unique properties make it an indispensable material for many demanding applications.

- High Thermal Stability: It has an incredible ability to withstand high temperatures, maintaining its strength even in environments where most metals would melt.

- Excellent Thermal Conductivity: It is fantastic at dissipating heat, a crucial property for molds and heat sinks.

- Low Coefficient of Thermal Expansion: It doesn’t expand or contract much with temperature changes, ensuring dimensional stability.

- Superior Electrical Conductivity: It is an excellent conductor of electricity, making it the perfect material for graphite electrodes and graphite brushes.

However, these wonderful properties come with a catch. For machinists, graphite’s nature is a double-edged sword. While it is soft, it is also extremely abrasive at a microscopic level. The particles that flake off during machining act like fine-grit sandpaper, leading to rapid tool wear. Furthermore, graphite is a brittle material. It doesn’t bend or deform under pressure; it fractures. This means it can easily chip or crack if the wrong machining processes or tools are used. Understanding graphite‘s dual nature—soft yet abrasive, strong at high temperatures yet brittle at room temperature—is the first and most critical step to successful graphite machining.

What are the Different Grades of Graphite and Why Do They Matter?

A common mistake is thinking that all graphite is the same. Nothing could be further from the truth. There are many different grades of graphite, and the specific grade you choose has a massive impact on both its final application and the ease of the graphite machining process. The primary difference between graphite grades comes down to the size of the particles or grains in the raw material mix and the final density of the material.

- Coarse-Grain Grades: Made with larger particles. They are generally less expensive but have lower strength and hardness. They are more prone to chipping during machining and cannot achieve a fine surface finish. They are often used for applications like large heating elements where precision is less critical.

- Medium-Grain Grades: A good all-around choice, balancing cost and performance. They are suitable for many applications, including graphite crucibles and molds.

- Fine-Grain and Ultrafine-Grain Grades: Made with tiny particles, resulting in a very dense and strong material. These grades are ideal for high-precision machining of intricate parts like EDM electrodes. They can be machined to very tight tolerances with an excellent surface finish. The trade-off is that their dense, hard nature causes even faster tool wear, making diamond-coated tools a necessity.

What are the Major Benefits of Graphite Machining for Modern Industries?

So why do industries invest so much in mastering graphite machining techniques? The benefits of graphite machining are profound and enable technologies that would otherwise be impossible. The primary benefit is the ability to create highly customized and complex shapes from a material with unparalleled performance characteristics. In electrical discharge machining (EDM), for instance, a precisely machined graphite electrode is used to burn intricate shapes into hardened steel for creating injection molds. The precision of the final mold is directly tied to the precision of the graphite electrode.

In the aerospace industry, graphite components are machined into rocket nozzles and heat shields that can withstand the extreme temperatures of atmospheric re-entry. In metallurgy, large graphite blocks are machined into molds for continuous casting of metals. The ability to mill, drill, and turn graphite allows us to harness its thermal stability and conductivity to create parts that are perfectly tailored to specific applications. This process unlocks a level of precision and efficiency that is critical for high-tech manufacturing.

The Graphite Machining Process: A Step-by-Step Overview

The graphite machining process shares some similarities with other machining operations, but with key differences. Whether done manually or with CNC machines, the basic steps are similar, though CNC graphite machining is vastly superior for consistency and complexity.

- Fixturing: The graphite block is secured to the machine bed. Because it’s brittle, this must be done carefully to distribute pressure evenly and avoid cracking. Vacuum chucks or soft jaws are often used.

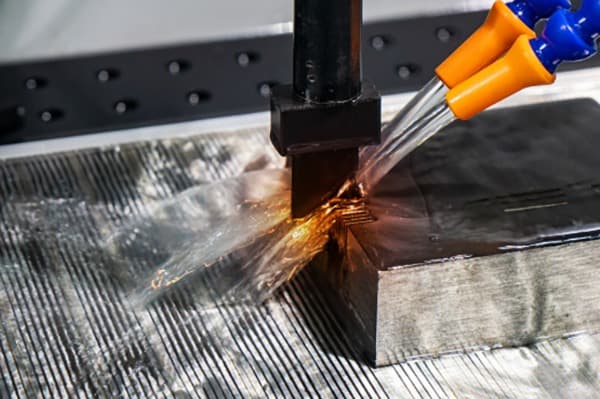

- Roughing: The first stage involves removing large amounts of material to get the workpiece close to its final shape. This is typically done with a larger cutting tool at a high material removal rate.

- Finishing: The final stage uses a smaller, sharper cutting tool to machine the part to its final dimensions and achieve the desired surface finish. This requires a lighter cut and precise control over the feed rate.

- Detailing: For intricate graphite components, further steps may be needed to create fine details, sharp corners, or deep pockets using specialized tools and techniques.

- Cleaning and Inspection: After machining, the part must be thoroughly cleaned to remove all graphite dust and then inspected to ensure it meets all dimensional tolerances.

Throughout this entire process, effective dust management is not an optional extra—it is a core part of the operation.

How to Select the Right Cutting Tool for Working with Graphite?

Your choice of cutting tool is one of the most critical factors in successful graphite machining. Due to the material’s highly abrasive nature, standard high-speed steel (HSS) tools are useless; they will become dull in seconds. Even uncoated solid carbide tools, which are very hard, will experience rapid tool wear. This doesn’t just mean you’ll be replacing tools constantly; a dull tool will also cause chipping and result in a poor surface finish.

The solution is to use specialized coated tools. Here’s a quick guide:

- Uncoated Carbide: Can be used for short runs or roughing, but expect a very short tool life.

- PVD Coated Carbide: Coatings like TiN (Titanium Nitride) or AlTiN (Aluminum Titanium Nitride) offer a moderate improvement in wear resistance.

- Diamond Coated Carbide: This is the gold standard. A thin layer of industrial diamond is applied to a carbide tool through processes like Physical or Chemical Vapor Deposition. This creates an incredibly hard and slick cutting surface that can withstand graphite’s abrasiveness for a much longer time. While more expensive initially, diamond-coated tools provide the best performance and lowest cost-per-part in any kind of high-volume production.

Mastering Graphite Machining Techniques: Speeds, Feeds, and Cuts

Once you have the right cutting tool, you need to use it correctly. Machining graphite is a game of finesse, not brute force. The general rule of thumb is "go fast, but light." This translates to using higher spindle speeds (RPM) and a moderate feed rate.

High spindle speeds reduce the amount of time the cutting edge is in contact with the material, which helps to minimize tool wear. A light, or moderate, feed rate reduces the cutting pressure on the brittle graphite material, which is the key to preventing chipping and fracturing, especially on corners and thin walls. Pushing the machine too hard will not make the process faster; it will only lead to broken tools and scrapped parts. It’s always better to take multiple shallow passes than one deep, heavy cut. This approach, combined with a sharp cutting tool, is how you achieve a smooth, precise surface finish on your graphite parts.

The Elephant in the Room: Effective Dust Management Solutions

We cannot talk about graphite machining without dedicating a serious discussion to dust control. The fine, black graphite dust created during machining is the number one challenge. It’s not just messy; it’s dangerous.

- It’s Conductive: Graphite dust is electrically conductive. It can get into the electronics of your CNC machine and cause short circuits, leading to catastrophic and expensive failures.

- It’s Abrasive: The same abrasive dust that wears down your tools will also destroy your machine. It gets into ball screws, linear guides, and bearings, mixing with lubricants to form a grinding paste that rapidly wears down precision components.

- It’s a Health Hazard: Inhaling fine dust of any kind is bad for your lungs, and graphite is no exception.

Effective dust management is non-negotiable. This means using a powerful vacuum system with a capture hood placed directly at the cutting site to suck up the dust as it’s created. This air should then be run through a multi-stage filtration system with dust collectors to trap the particles. Full enclosures on machining centers and proper ventilation are also essential parts of any professional graphite machining setup.

What are the Advantages of Using a Specialized CNC Machine for Graphite?

While you can retrofit a standard CNC mill for working with graphite, for any serious production, a specialized graphite machining center is a far better investment. These machines are designed from the ground up to handle the unique challenges of the graphite material.

A purpose-built graphite machine will have all its sensitive components—like the control electronics, ball screws, and guide rails—completely sealed and protected from the conductive, abrasive dust. They are typically equipped with high-speed spindles designed for the high RPMs needed for graphite and often come with an integrated, high-efficiency dust extraction system. They are also built for rigidity to handle high-speed movements without vibration, ensuring maximum precision. While a standard machine might get the job done for a short time, it will inevitably suffer premature wear and failure. A specialized machine is built for a long, productive life in the harsh graphite environment.

Real-World Applications: Where is Graphite Machining Utilized?

The fruits of the graphite machining process are all around us, enabling many modern technologies. At our factory, Tuoda, we produce a wide range of various graphite components for global clients.

- Metallurgy: This is one of the biggest users. We machine massive High-power graphite electrodes for electric arc furnaces used in steel recycling. We also create precision graphite crucibles used for melting precious metals and specialty alloys.

- EDM: The tool and die industry relies on highly detailed graphite electrodes to create molds for everything from car parts to phone cases.

- Aerospace: Graphite components are machined into rocket motor nozzles, nose cones, and heat shields due to their phenomenal ability to withstand high temperatures.

- Semiconductors: Ultrapure graphite is machined into susceptors and heating elements used in the production of silicon wafers.

The list goes on, from glass manufacturing and continuous casting to furnace linings and bearings. In each case, graphite machining is the key enabling technology that transforms a simple block of carbon into a high-performance industrial component.

Post time: 09-29-2025