Fais arc rauv taws (EAF) ua haujlwm raws li pob zeb ntawm niaj hnubsteelmaking, muab cov khoom siv tau yooj yim thiab ua haujlwm tau zoo, tshwj xeeb tshaj plaws hauv kev rov ua dua tshiabSeem Hlau HlauCov. Ntawm lub siab heev ntawm cov txheej txheem muaj zog no yog covGraphite electrodesCov. Cov no tsis yog cov pas nrig yooj yim; Lawv tau muaj kev tsim kho tau zoo heev rau kev xa cov lojHluav Taws Xob Hluav Taws Xobxav tauMelt SeemthiabTsim Cov HlauCov. Nkag siab txog txoj haujlwm, hom kev ua tau zoo, thiab ua kom zoo ntawm cov noCov Hluav Taws Xobyog qhov tseem ceeb rau ib qhoFais arc rauvTus tswj hwm, tus thawj tswj hwm pom, lossis tus kws tshaj lij tshwj xeeb zoo li Mark Thompson tsom rau kev ua tau zoo thiab raug nqi zoo. Cov lus no rho tawm tob tob rau hauv lub ntiaj teb ntawmarc rauv electrodes, piav qhia vim li casnpaimyog cov khoom siv ntawm kev xaiv, yuav ua li caslub nkojUa haujlwm nws cov khawv koob nyob hauvqho cub, dab tsi txhais tau zookhoom siv hluav taws xob, thiab ua khub sib koom ua ke nrog cov kws tsim kev paub tau zoo li peb, nrog 7 cov kab ntau lawm nyob ntawm Suav teb, tuaj yeem tiv thaiv koj txoj haujlwm. Peb yuav tshawb xyuas txhua yam los ntawm Phau Ntawv MaumoosCov Khoom Siv Rawrau zaum kawgTxheej txheem stugmaking, ua kom koj muaj kev nkag siab xav tau los ua kev txiav txim siab.

Dab tsi yog qhov hluav taws xob arc rauv taws (EAF) thiab nws yuav yaj tau li cas?

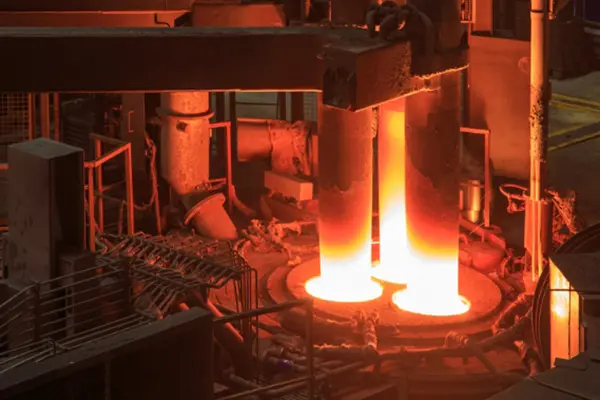

IbFais arc rauv, feem ntau cov tsiaj ntawv luv li eaf, yog hom ntawmqho cubuasCua sovthem cov khoom uas feem ntau ntawm txoj kevFais arcCov. Xav txog nws yog Kettle loj heev, tab sis hloov chaw ua cua sov, nwsyajtons ntawmSeem Hlau HlauThiab lwm yam xim hlau siv siv cov kub siab heev tsim los ntawm hluav taws xob. Tej nolub tshuab ziabyog cov haujlwm ua haujlwm hauvKev lag luam hlau, tshwj xeeb yog nyiam rau lawv lub peev xwm ua tau zoo rau kev ua tau zooSeem Hlau, ua tusTxheej txheem stugmakingNtau ntxiv sib piv rau ib txwm muajmoj tej tawg rauvuas cia siab rau hlau ore. Cov qauv theem pib cuam tshuam nrog lub nkoj refactionel (covqho cubplhaub), lub ru tsev nrog ports rau lubCov Hluav Taws Xob, thiab tus tapping spout kom ncuav tawm lubMolten Steel.

Cov txheej txheem pib los ntawm kev thau khoom lubqho cubnrogSeem Hlau Hlau(tus thawjfeedstock) thiab qee zaum lwm yamCov Khoom Siv RawZoo li cov hlau txo cov hlau (dri) lossis npua npua. Ib zaug thauj khoom, lub ru tsev yog viav vias mus rau hauv qhov chaw, thiab covGraphite electrodesyog txo qis rau covseemCov. Ib qho hluav taws xob tsis tshua muaj hluav taws xobtam sim no hla dhau ntawm electrodeTsim muaj zogHluav taws xob arcsnruab nrab ntawmCov Lus Qhia Cov Ntawvthiab tus nqi yuav khoom. Nolub nkojtsimkhaus tshav kub, mus txog kub uas tuaj yeem tshaj 3,000degrees Celsius(Mus cuag5000 degreesFahrenheit nyob rau hauv arc nws tus kheej), uas saiMelts cov seem steelCov. Tag nrhoqho cubfeem ntau zaum ntawm aTilting Platformkom tso cai rau lub pouring ntawm lubMolten SteelThaum xav taukub thiab chemistryua tiav.Eafsyog veratile, muaj peev xwm ntawm kev ua tau ntau yam ntawmCov Qib Qauv Hlau.

Kev ua tau zoo thiab nrawm ntawm lubFais arc rauvtau ua nws txoj kev siv thev naus laus zis hauvsteelmakingthoob ntiaj teb. Tsis zoo liInduction Rauvuas siveddy kurentsrauqho kubcov hlau, tusEafsiv ncaj qhaqho kubntawm lubFais arc rau yajTus nqi. Daim ntawv thov ncaj qha ntawmHluav Taws Xob Hluav Taws XobTso cai rau kev siv lub voj voog sai sai. Tusqho cubnws tus kheej yuav tsum muaj zog, nrog lub plhaub feem ntaulined nrog refractoryCov ntaub ntawv zoo liRefract Triblerautiv taucov xwm txheej huab. Niaj hnubEafsteeb tsa cov tshuab siab siab,Dej-Txiaspanels rau cov phab ntsa thiab lub ru tsev, thiab ruaj khov kho tshuab rau kev tuav covCov Hluav Taws Xobthiab tswj covyaj.

Yuav ua li cas graphite cov hluav taws xob tsim kom muaj qhov kub ua kom sov xav tau hauv EAF rauv taws?

Khawv koob ntawmFais arc rauvlus dag nyob rau hauv lubFais arcnws tus kheej, thiab covGraphite electrodesyog cov conduits uas ua rau nws tshwm sim. Feem ntau,Peb electrodesyog siv rau hauv AC (hloov tshiab tam sim no)qho cub, npaj nyob rau hauv ib tug qauv duab sab nraud. Tej nolub cylindricalTxhua ntawmnpaimua li terminals rau lub zog hluav taws xob muab hluav taws xob, txuas nrog ntawmCov dej loj-cableCov. Thaum lubCov hluav taws xob raug txo qisZe rau cov xim hlau (Seem Hlau Hlau) sab hauvqho cub, ib feem ntau voltage yog thov. Qhov no voltage ionizes huab cua (lossis roj av) hauv qhov sib txawv ntawm covkhoom siv hluav taws xobntsis thiab tusseem, tsim txoj kev ua kom pom tseeb.

Thaum txoj kev no tau tsim, ib qho loj heevLub Hluav Taws Xob Tam Sim No(kaum txhiab txhiab tusAMIVES) ntws los ntawm covCov Hluav Taws Xobthiab jumps hla kev sib txawv, tsim kev txhawb nqaFais arcCov. Nolub nkojyog qhov tseem ceeb ua ib qho txuas ntxiv mus ntxiv, muaj ntshav tawm ntawm ntshav. Nws convertsHluav Taws Xob Hluav Taws Xobrau hauv thermallub zognrog kev ua tau zoo tshaj plaws, tso kev sib luagqho kubncaj qha rau hauvSeem HlauCov. Nws yog tus mob siab no,khaus tshav kublos ntawmlub nkoj(lossisarcs, nyob rau hauv ib tug peb-khoom siv hluav taws xobTeeb) uas yog lub zog nqa, sai sai yaj lubseemthiab sib sau aMolten pas dejCov. TusCov Hluav Taws Xobyog precisely tswj tau los tswj hwm qhov zoo tshaj plawslub nkojntev thiab ruaj khov thoob plaws hauv cov txheej txheem melting.

Lub zog xa los ntawmCov Hluav Taws Xobyog loj heev. Xav txog lub zog uas yuav tsum muajyajtons ntawm cov khoomhlauHauv qab ib teev - uas yog cov nplai peb tab tom ua haujlwm ntawm. TusCov Hluav Taws Xoblawv tus kheej tau noj thaum lub sijhawm tus txheej txheem no vim yogoxidationntawm lawv cov lus qhia thiab sublimation nyob rau hauv huabqho kubntawm lublub nkoj, tab sis lawv txoj haujlwm tseem ceeb yog los ua qhov tsim nyog tam sim no thiab txhawb nqa lublub nkojyuav tsum taukub thiab yajlub txim ua tau zoo. Qhov kev ruaj khov thiab siv covlub nkojQhia ncaj qha rau covqho cub'Cov khoom lag luam thiabKev Siv Zog, qhia txog lub luag haujlwm tseem ceeb ntawm lubkhoom siv hluav taws xobSystem.

Vim li cas thiaj li graphite cov ntaub ntawv tsis muaj rau arc rauv electrodes?

Cov xwm txheej hauv ibFais arc rauvyog xav tau kawg. Qhov kub thiab txias, hluav taws xob ntws tawm yog qhov loj, thiab thermal poob siab yog khaus. Yog li, yog vim li casnpaim? Vim li cas tsis tooj liab lossis tungsten? Cov lus teb nyob rau hauvnpaim'S tshwj xeeb ua ke ntawm cov yam ntxwv, ua rau nws zoo tshaj plaws haum rau kev pabcuam ua ib qhokhoom siv hluav taws xobNyob rau hauv cov cheeb tsam loj. Ua cov chaw tsim khoom lag luam, peb cia siab rau ntawm cov yam ntxwv hauv cov yam ntxwv hauv no.

Firstly,npaimmuaj tshwj xeebthermal conductivityThiab kev tiv thaiv zoo heev rau kev poob siab. Qhov no txhais tau tias nws tuaj yeem ua tautiv taukev hloov pauv kub sai uas muaj kev paub txog thaum lublub nkojstrikes thiab thaum lub sij hawm melting txheej txheem tsis yooj yim tawg los yog swb.Graphite tuaj yeem tiv thaivkub heev nyob deb tshaj plaws lub suab nrov ntawmhlauCov. Thib ob,npaimtswj hwm nwsNeeg Kho Tshuab Muaj Zogzoo kawg li ntawm heevKev kub siabtheem, tsis zoo li cov hlau uas tsis muaj zog ntau. Cov qauv kev cai no tseem ceeb heev rau lub sijhawm ntevkhoom siv hluav taws xobTxhua siv nyob rau hauv lojlub tshuab ziab.

Thib peb, thiab crucially rau ib qhokhoom siv hluav taws xob, npaimmuajTsawg Tshaj Hluav Taws Xob(lossis hluav taws xob siab siv hluav taws xob). Qhov no tso cai rau nws nqa cov dej khov loj uas yuav tsum tau ua rau lublub nkojtsis muaj cua sov ntau dhau (qho kubpoob) lossis voltage poob. NwsKev tiv thaiv qisua kom muaj zog hloov hluav taws xob rau covyajCov. Plaub,npaimMuaj ib tug heev sublimation taw tes (nws hloov ncaj qha los ntawm khoom rau roj) es tsis yog qhov taw tes tsawg. Thaumkhoom siv hluav taws xobTau Siv Los Ntawmoxidationthiab sublimation tshwm sim,npaimQhov muaj peev xwm ua kom muaj peev xwm ua kom thev dhau cov kev mob no nyob deb tshaj rau lwm cov ntaub ntawv muaj peev xwm. Cov txheej txheem tsim khoom, muaj kev cuam tshuam nrogduabThaum kawg kub heev, ua kom haum rau cov tshuaj carbon cov qauv los ua kom zoo dua cov noThermal thiab Hluav Taws Xobcov khoom. Nws yog qhov kev sib xyaw no thermal resilience, siab-kub lub zog, thiab hluav taws xob conductivity uas ua raunpaimCov khoom siv tsis tau rauarc rauv electrodes.

Cov qhab nia sib txawv ntawm cov graphite electrode muaj nyob rau steelmaking rauv taws? (UHP, HP, RP piav qhia)

Tsis yog txhua tusFais arc rauvyog tsim sib npaug, thiab tsis yog tusGraphite electrodesLawv siv. Qhov xav tau tso rau ntawm ib qhokhoom siv hluav taws xobsib txawv heev nyob ntawm tusqho cubLub hwj chim ntaus nqi, kev khiav hauj lwm cov kev coj ua, thiab homhlauraug tsim tawm. Kom tau raws li cov kev xav tau sib txawv no,Graphite hluav taws xob yog sivHauv cov qhab nia sib txawv, feem ntau tau cais los ntawm lawv cov peev txheej tam sim no thiab cov khoom siv lub cev. Ua lub Hoobkas zoo li peb li, peb tsim cov khoom ntawm cov no kom cerable cov neeg siv khoom.

Cov qhab nia tseem ceeb rauarc rauv hluav taws xob hluav taws xob:

- Lub zog tsis tu ncua (RP):Tej noCov Hluav Taws Xobyog tsim los rau qis-poweredFais arc rauv, feem ntau cov siv hauv kev ua kom pom lossis tsawg dua xav tausteelmaking. Lawv siv cov qauv khoom zoo roj avcoekThiab muaj qhov tseem ceeb tam sim no tsis muaj peev xwm ntev.

- Muaj Zog Muaj Zog (HP):HpCov Hluav Taws XobMuab cov kev ua tau zoo dua li RP qib. Lawv tau tsim kev siv roj av ntau duacoekThiab tuaj yeem tswj cov qhov ntau dua tam sim no. Cov no haum rauFais arc rauvKoom Tes Nrog Tus Qauvsteelmakingthiab ua haujlwm ua haujlwm. Koj tuaj yeem tshawb nrhiav cov kev xaiv zoo li pebHigh-fais fab graphite electroderau kev ua tau zoo hauv cov ntawv thov no.

- Ultra-Siab Fais Fab (UHP):Cov no yog cov sab saum toj-tierCov Hluav Taws Xob, engineered rau cov feem ntau xav tauFais arc rauvCov ntawv thov.UHP Electrodesyog tsim tau siv lub koob hwm hwmcoek, uas muab cov qauv zoo dua, txo hluav taws xob tsis kam, siab dua, thiab zoo dua tsis kam rau cua sov thiaboxidationCov. Lawv tuaj yeem tiv taus ntau tam sim no qhov ntev tam sim no, ua rau lawv tseem ceeb rau loj, muaj kev tsim khoom lojEafssiv rauUa Hlausai thiab zoo. Peb liUltra-Siab Fais Fab Graphite Hluav Taws Xobyog tshwj xeeb yog tsim rau cov chaw nyuaj no. Rau qhov loj tshaj plawslub tshuab ziab, Tshwj XeebTxiaj Ntsig Loj Loj Graphate electrodeQhov ntau thiab tsawg no.

Qhov kev xaiv ntawmkhoom siv hluav taws xobQib cuam tshuam ncaj qha cuam tshuamqho cubefficiency,khoom siv hluav taws xobCov nqi siv tau, thiab cov nqi khiav haujlwm tag nrho. Siv qib qis duakhoom siv hluav taws xobNyob rau hauv lub siab-zogqho cubua rau noj haus ceev ceev thiab muaj peev xwm tawg, thaum siv aUhp electrodenyob rau hauv lub zog-zogqho cubtej zaum yuav tsis kim. Txuam raukhoom siv hluav taws xobQib rau covqho cubYuav tsum muaj qhov tseem ceeb rau kev pom zooEAF Steelmaking.

Koj puas tuaj yeem piav qhia txoj kev taug: Yuav ua li cas yog ib tug zoo-zoo graphite tsim?

Tsim ibGraph kaw electrodemuaj peev xwm ua tau raws li hauvFais arc rauvyog ib qho nyuaj, ntau theem txheej txheem uas xav tau precision thiab ua tib zoo tswjCov Khoom Siv Rawthiab ua cov tsis muaj. Raws li cov tuam ntxhab, peb saib xyuas cov lus no zoo heev. Nws pib nrog xaiv cov pa roj carbonaceousCov Khoom Siv Raw, feem ntau zoo-zoo roj avcoek(Tshwj xeeb rab koobcoekrauUHP Electrodes) thiab pob zeb pob zeb ua cov phau ntawv.

Cov txheej txheem feem ntau cuam tshuam nrog cov kauj ruam tseem ceeb no:

- Nws:Tus calcinedcoekCov lus yog ua tib zoo rau qhov loj thiab sib xyaw nrog molten quav pob zeb pob zeb. Cov feem sib npaug thiab kev sib xyaw zoo yog qhov tseem ceeb rau qhov kawgkhoom siv hluav taws xobcov khoom.

- Txoj kev sib sau (extrusion lossis molding):Cov tshuaj tiv thaiv cua sov-zoo li sib xyaw yog tom qab ntawd tsim rau hauv qhov xav taulub cylindricalcov duab, feem ntau dhau los ntawm kev rho tawm rau cov qauv ntau thiab tsawg molding rau ntau heevCov Hluav Taws Xoblossis cov duab tshwj xeeb. Cov ntawv no "ntsuab"khoom siv hluav taws xob.

- Ci:NtsuabCov Hluav Taws Xobyog maj mam rhuab nyob rau hauv loj cilub tshuab ziabtshaj li ntau lub lis piam kom kub ib ncig 800-1000degrees CelsiusCov. Cov txheej txheem no carbonizes cov suab paj nruag cov ntawv cim, tsim cov qauv carbon ua qauv thiab tsav tsheb tawm cov khoom siv. Ceev faj qhov kub thiab txias kev tswj yog qhov tseem ceeb kom tiv thaiv kev tawg.

- IMPREGNATION (yeem tab sis ib txwm muaj rau HP / UHP):Kom nce ntom ntom thiab lub zog, ciCov Hluav Taws XobFeem ntau impregnated nrog kua pitch nyob rau hauv siab thiab tom qab ntawd rov qab. Qhov no ua rau paces sab hauv.

- Graphitizitizitization:Qhov no yog qhov tseem ceeb tshaj plaws thiab lub zog-thev naus laus zis. Lub ciCov Hluav Taws Xobyog rhuab hauv tshwj xeebCov Hluav Taws Xob Cov Hluav Taws Xob(zoo li Achesonlub tshuab ziab) rau qhov kub siab kawg, feem ntau ntawm 2500 thiab 3000degrees CelsiusCov. Qhov khaus noqho kubhloov cov amorphous carbon miroch rau crystallinenpaimCov. Noduabkauj ruam yog dab tsi imparts zoo heevThermal thiab Hluav Taws Xobconductivity yuav tsum muaj rauEAF Electrodes.

- Machining:Tom qab txias, lub graphitizedCov Hluav Taws Xobyog precision-machined rau qhov ntev. Qhov no suav nrog txiav lawv kom ntev thiab tsim cov khoom throuted ntawm txhua qhov kawg. Cov thom khwm no tso cai rau tus neegCov Hluav Taws Xobyuav tsum tau koom nrog ua ke siv txuas pins (txiv mis), kuj ua los ntawmnpaim, los ua cov kab ntev uas mus txog rau hauvqho cubCov. Qhov precision ntawm lubtxoj xovyog ib qho tseem ceeb rau muaj zog, cov pob qij txha tsis tshua muaj.

Thoob plaws hauv no cov txheej txheem no, kev tswj hwm nruj zoo tswj tau yog ua, los ntawm cov ntaub ntawv tsom xam cov khoom siv zaum kawgkhoom siv hluav taws xobCov. Nws yog txoj kev taug los ntawm kev xaiv zooCov Khoom Siv Rawrau cov khoom lag luam zoo tsim tsim rautiv tauLub txim rau ib puag ncig ntawm ibFais arc rauv.

Dab tsi ntawm qhov tseem ceeb qhov kev kuaj xyuas qhov tseem ceeb ntawm cov khoom siv hluav taws xob thaum lub cub hluav taws xob melt?

Rau steelmakers zoo li Malompson, zoo ib yamkhoom siv hluav taws xobKev ua tau zoo yog qhov tseem ceeb. Unforeseen ua tsis tiav lossis qib siab siv tau tuaj yeem cuam tshuam cov sijhawm ua haujlwm thiab nce nqi. Yog li ntawd, kom ntseeg tau qhov zoo ntawmGraphite electrodestsis yog ib qho kev tawm dag zog checkbox; Nws yog qhov tseem ceeb rau kev ntseeg siabFais arc rauvkev ua haujlwm. Ntawm peb lub hoobkas, kev tswj hwm zoo yog ua ke rau txhua theem, los ntawm cov khoom siv raw rau cov zaub mov xa tuaj kawg.

Cov Ntsiab Lus Tseem Ceeb Peb tsom rau xws li:

- Cov khoom siv raw zoo:Xyuas cov yam ntxwv ntawm cov roj avcoekthiab Suab binder. Rab koobcoekzoo yog qhov tseem ceeb tshaj plaws rauUHP Electrodes.

- Qhov Tseeb Docensional:Kom ntseeg taukhoom siv hluav taws xobtxoj kab uas hla, ntev, thiab qhov tseem ceeb, qhov precision ntawm lub tshuabtshuab thiab txuas lub txiv mis (txoj xovQhov tseeb) Ua kom tiav nruj Daj. Tsis zoo cov pob qij txha ua rau hluav taws xob tsis kam thiab muaj feem xyuam tsis ua haujlwm.

- Lub cev lub cev:Kuaj cov qauv los ntawm txhua cov khoom lag luam ntau lawm rau cov khoom tseem ceeb li:

- Qhov ceev ceev ntom ntom:Ntau dua ntom feem ntau qhia tau zoo dua qub thiab kev noj qis dua.

- Hluav Taws Xob Tiv Thaiv:Qis dua kev ua haujlwm tau zoo dua thiab tsawg zog poob nyob rau hauvkhoom siv hluav taws xobCov. Qhov no tseem ceeb heev rauThermal efficiency.

- FLEXURAL HWJCHAV & Modulus ntawm Elasticity:Cov no qhia covkhoom siv hluav taws xobSNeeg Kho Tshuab Muaj Zogthiab tsis kam mus rau cov rog dabtsi yog thaum tuav thiab ua haujlwm hauv Phau Ntawv Maumoosqho cub.

- Coefficient ntawm thermal expansion (CTE):Tsawg CTE pab tuselectrode withstandThermal poob siab.

- Cov ntsiab lus tshauv:Cov ntsiab lus tshauv qis yog ntshaw kom txo cov impurities tau qhia rau hauvhlau yaj.

- Cov Txheej Txheem Kev Ncaj Ncees:Siv cov kev kuaj sim tsis yog (zoo li kev sim tshuaj) txhawm rau kuaj xyuas cov kab nrib pleb lossis qhov tsis txaus ntseeg uas yuav ua rau muaj kev ntxhov siab lossisqho kubnyob rau hauv lubFais arc rauv.

- Daim ntawv pov thawj thiab muaj kev sib tw:Muab cov ntawv ceeb toom xeem tshaj plaws thiab cov ntawv pov thawj (piv txwv li (.O 9001 ua raws li cov khoom siv tshwj xeeb) rau txhua pob, ua kom muaj kev vam meej ntawm kev xa khoom. Hais txog kev txhawj xeeb txog daim ntawv pov thawj kev dag yuav tsum tau pob tshab thiab cov ntaub ntawv muaj zog los ntawm cov khoom lag luam.

Cov tshev no sib sau ua ke kom paub tseeb tias covCov Hluav Taws XobCov khoom siv tuaj yeem lis cov hluav taws xob teev, tiv thaiv lub pob luj tawsqho cubIb puag ncig (khaus tshav kub, thermal poob siab, kev nyuaj siab kev ntxhov siab), thiab muab cov qhab nia dhau los, tso caisteelmakersua haujlwm lawvEafszoo thiab ntseeg tau.

Cov electrodes zoo li cas thiab ua ke rau hauv cov hluav taws xob arc rauv ua haujlwm?

Txawm tias qhov zoo tshaj plawsGraph kaw electrodetuaj yeem swb yog tias tsis daws thiab siv kom raug. Muab lawv qhov loj me, qhov hnyav, thiab txheeb ze brittleness piv rau cov khoom siv, cov txheej txheem tsim nyog yog qhov tsim nyog kom tiv thaiv kev puas tsuaj thiab ua haujlwm ruaj khov thiab ua haujlwm nyob rau hauvhlau zebCov. Peb ib txwm qhia peb cov neeg siv khoom ntawm kev coj ua zoo tshaj plaws.

Kov cuam tshuam nrog ua tib zoo nqaCov Hluav Taws XobSiv cov qauv tsim qauv los yog clamps, zam kev cuam tshuam uas tuaj yeem ua rau tawg. Cia yuav tsum nyob hauv ib thaj chaw huv thiab qhuav, tiv thaiv los ntawm kev puas tsuaj rau kev puas. Thaum npaj ibkhoom siv hluav taws xobsab, txoj xov throuted ntawm lubkhoom siv hluav taws xobthiab lub txiv mis yuav tsum tau huv huv kom tshem tawm cov hmoov av lossis cov khib nyiab, uas tuaj yeem ua rau hluav taws xob tsis kam. Thov qhov tseeb torque thaum zawm cov pob qij txha yog qhov tseem ceeb - ua kom nruj kev ua rau muaj kev tiv thaiv siab thiab kub ntxhov, thaum muaj kev puas tsuaj rau kev puas tsuaj rau cov xov lossiskhoom siv hluav taws xobqauv. Tshwj xeeb Torque wrenches yog siv rau qhov no.

Thaum sib sau ua ke rau hauv txhua, tusCov Hluav Taws Xobyog mounted mus rau hauvkhoom siv hluav taws xobcaj npab ntawm lubFais arc rauvCov. Tej caj npab, txuas nrog lub zog hluav taws xob ntawmCov dej loj-cable, cia covCov Hluav Taws Xobyuav tsum tau tsa, txo qis, thiab swung ib sab rau them tusqho cubCov. Thaum lub sijhawm ua haujlwm, tuskhoom siv hluav taws xobCov cai txheej txheem ua tau kho txoj haujlwm ntawm txhua tuskhoom siv hluav taws xobTxhawm rau tswj ruaj khovlub nkojthiab tswj cov tswv yim fais fab. TusCov hluav taws xob raug txo qiszuj zus raws li tusseem qawsdown thiab raws li tusCov Lus Qhia Cov Ntawvtau noj. Saib xyuas cov neeg ua haujlwm saib xyuaskhoom siv hluav taws xobUa tau, nrhiav cov cim ntawm kev noj ntau dhau, zais cais ua kom sib cais, lossis cov teeb meem sib koom tes. Xyuam xim ua haujlwm yuav pab ua kom ntau tshajkhoom siv hluav taws xoblub neej thiab tswj xwm txheejqho kubCov tswv yim rau tusyaj.

Cov teeb meem dab tsi tshwm sim tshwm sim nrog electrodes thaum lub sij hawm yaj ua tau lawv yuav ua li cas thiaj li raug ntxias?

Txawm tias muaj kev ua kom muaj zog,Graphite electrodesKev khiav hauj lwm ntawm kev txwv ntawm cov khoom ua kom ntev ntev li qubFais arc rauvCov. Muaj ntau cov teeb meem tuaj yeem tshwm sim thaum lub sijhawm xav tauyajKev ua voj voog, kev cuam tshuam kev ua haujlwm thiab tus nqi. To taub cov kev pab ua haujlwm thiab muaj peev xwm cov thawj coj thiab cov thawj coj ua tus cim ua cov kev xaiv zoo dua thiab muaj teeb meem daws teeb meem zoo dua.

- Kev siv ntau:Nov yog kev txhawj xeeb tshaj plaws. Tau tshwm sim los ntawm:

- Tswv yim sublimation:Carbon vaporizing ncaj qha los ntawm lub taub nyob rau hauv huabqho kubntawm lublub nkoj.

- Oxidation:Carbon reacting nrog oxygen nyob rau hauv lubqho cubcua raws li txoj kev taug ko taw ntawmkhoom siv hluav taws xobCov. Qhov no feem ntau yog cov feem ntau feem ntawm kev noj.

- Breakage:Neeg kho tshuab tsis ua haujlwm ntawm lubkhoom siv hluav taws xobkem lossis sib koom ua ke.

- Mitigation:Siv qhov tseebkhoom siv hluav taws xobQib (piv txwv li,UhpRau lub zog siab), ua kom zoo duaqho cubSealing los txo cov pa cua (txo qisoxidation), tswj kev sib koom ua ke kom nruj, ua kom ruaj khovlub nkojkev cai, thiab qee zaum siv cov txheej txheem tiv thaiv lossisDej-TxiasTxau ib ncig tuaj yeem pab tswj kev noj haus.

- Breakage:Ua ciavkhoom siv hluav taws xobUa tsis yog cuam tshuam thiab kim heev. Ua rau:

- Thermal poob siab:Qhov kub sai hloov pauv, tshwj xeeb tshaj yog thaum pib lossis yog dej xau.

- Neeg kho tshuab:Cov khoom tsis yog coj los poob los ntawm lub ru tsev, ntau dhau lawm tshee, lossis seem collapses cuam tshuam covkhoom siv hluav taws xob.

- Ua Neeg Txhaum Cai:Tsis yog lub zog torque lossis qias neeg uas ua rau overheating thiab sib koom ua ke.

- Sab hauv tej yam:Kev tsim cov nyom tsis huv (txawm tias yog QC minimizes qhov no).

- Mitigation:Ceev fajseemKev tswj hwm, ua ke sib koom ua ke, ua ntej cua sovCov Hluav Taws XobYog tias tsim nyog, ib txwmqho cubtxij nkawm, thiab siv cov khoom zooCov Hluav Taws Xobnrog zooNeeg Kho Tshuab Muaj ZogThiab thermal poob siab kuj.

- Ntxeev splitting / cracking:Tuaj yeem tshwm sim vim muaj cua sov sai / cua txias cycles lossis inconistencies nyob rau hauvkhoom siv hluav taws xobqauv. Zoo-zoo, homogenousCov Hluav Taws Xobyog tsawg tus nquag rau qhov no.

- Kev Kub Hluav Taws Xob Kub:Feem ntau tshwm sim los ntawm xoob lossis qias neeg pob qij txha, ua rau kom overheating, nceKev Siv Zog, thiab muaj peev xwm sib koom ua tiav. Kev tu kom tu thiab raug torquing yog qhov tseem ceeb.

Daws cov teeb meem no yuav muaj kev sib xyaw ua ke ntawm kev siv cov khoom zooGraph kaw electrode, siv cov kev ua haujlwm zoo tshaj plaws nyob hauvhlau zeb, thiab tswj covFais arc rauvkom yog. Kev sib txuas lus zoo ntawm covkhoom siv hluav taws xobtus xa khoom thiab covqho cubTus neeg teb xov tooj kuj tseem tseem ceeb rau kev kuaj mob thiab daws teeb meem.

Yuav ua li cas cov hlau mills xws li koj cov kev xaiv cov kev txhim khu kev qha graphite cov khoom xa khoom?

Rau Mark Thompson thiab lwm cov kws tshaj lij kev ua haujlwm, xaiv txoj caiGraph kaw electrodeTus xa khoom yog kev txiav txim siab tseem ceeb nrog kev ua haujlwm tseem ceeb thiab kev cuam tshuam nyiaj txiag. Pom tus khub uas muab cov nqi zoo sib xws, tus nqi sib tw, txhim khu kev qha txhim khu kev qha, thiab kev txhawb nqa zoo yog tseem ceeb heev yog qhov tseem ceeb. Cim cov ntsiab lus mob - chaw sib txuas lus tsis muaj zog, khoom xa tuaj qeeb, thiab daim ntawv pov thawj kev dag - qhia txog qhov tseem ceeb ntawm kev rau txim. Ntawm no yog qhov kuv, allen, pom zoo ua kom pom tseeb, raws li peb cov kev paub dhau los ua cov khoom lag luam zoo li Asmeskas, Europe, thiab Australia:

- Pov thawj manen kev txawj ntse:Saib kom tsim cov tuam txhab nrog cov kab ntau lawm (zoo li peb cov kab 7 thiab keeb kwm ntawm kev tsim cov qib tshwj xeeb tshwj xeeb (Uhp, HP, RP) koj xav tau. Kev paub txog teeb meem hauv mastering lub complexGraph kaw electrodekev tsim khoom. Mus saib lub Hoobkas, yog tias ua tau, lossis mus koom kev lag luam lojkev nthuav tawmQhov twg cov neeg muag khoom muab lawv cov peev xwm tuaj yeem muab cov kev pom zoo.

- Kev tswj hwm cov khoom lag luam zoo:Txheeb ntawm cov neeg xa khoom nrog cov ntawv pov thawj ua tau zoo (ISO 9001 yog qauv). Nug cov ncauj lus kom ntxaws txog lawv cov txheej txheem tswj hwm zoo, los ntawm raw khoom siv khoom siv (coekKev Ntsuam Xyuas) rau kev xeem kawg cov khoom lag luam (tiv taus, lub zog, ntom ntom, qhov ntev). Daim ntawv ceeb toom kev ntsuam xyuas thiab nkag siab lawv cov txheej txheem rau kom ntseeg tau tias yog-batch li. Tsis txhob cia li txais daim ntawv pov thawj; nug txog cov txheej txheem hauv qab nws sawv cev. Qhov no pab tawm tsam cov ntawv pov thawj kev dag ntxias.

- Kev Txhawb Nqa thiab Kev Sib Txuas Lus:Tus neeg xa khoom zoo ua raws li tus khub, tsis yog tus muag khoom nkaus xwb. Soj ntsuam lawv pab pawg kev paub. Lawv tuaj yeem muab tswv yim raukhoom siv hluav taws xobXaiv, tuav, thiab daws teeb meemqho cubCov teeb meem? Yog lawv cov pab pawg muag, paub txog tsuas yog kev sib tham muag), thiab yooj yim sib txuas lus nrog (daws cov lus tsis zoo yog tsim nyog)? Kev sib txuas lus tau zoo yog qhov tseem ceeb, tshwj xeeb tshaj yog thaum daws teeb meem sai.

- Logistics thiab kev ntseeg tau:Sib tham txog cov thawj lub sij hawm coj, kev xaiv shipping, thiab lawv cov ntaub ntawv taug qab rau cov khoom xa tuaj. Cov khoom xa tuaj tuaj yeem nressteelmakingkev ua haujlwm, yog li ntseeg tau yog qhov tseem ceeb. Nkag siab txog lawv cov hau kev kom tsis txhob muaj kev puas tsuaj thaum pib. Nug txog lawv cov kev tsim tawm rau koj lub tebchaws (Tebchaws Asmeskas, Tebchaws Europe, thiab lwm yam) thiab lawv cov kev paub nrog cov txheej txheem kev lis kev cai.

- Transparency thiab ntseeg:Saib rau cov neeg xa khoom uas qhib txog lawv cov txheej txheem thiab txaus siab muab cov ntaub ntawv ntxaws. Tsim lub tsev ntev kev sib raug zoo raws li kev ntseeg siab feem ntau muaj txiaj ntsig ntau dua li txuag tau ob peb daus las ibkhoom siv hluav taws xobnrog ib qho tsis paub lossis tsis paub meej. Sib thamKev Them NyiajUpfront thiab xyuas kom lawv muaj kev nyab xeeb thiab pob tshab.

- Kev sib tw nqi (tus nqi, tsis yog tsuas yog tus nqi):Thaum tus nqi yog ib txwm yog ib qho, tsom rau ntawm tus nqi tag nrho. Ib me ntsis pheej yig duakhoom siv hluav taws xobuas noj tau sai dua lossis tawg feem ntau yuav raug nqi ntau dua nyob rau hauv lub sijhawm ntev vim yog ploj ntau lawm thiab tau noj ntau dua ib tuj ntawmhlauCov. Soj ntsuam tus nqi nyob rau hauv cov ntsiab lus ntawm cov ntsiab lus zoo, muaj kev ntseeg tau, thiab kev txhawb nqa.

Nrhiav cov chaw muag khoom hauv Google tshawb yog ib qho muaj, tab sis ntxiv rau cov tshev tob, siv (yog tias ua tau), qee zaum pib ntawm ib qhochaws sauCov. Tus neeg muab khoom uas nkag siab txog qhov xav tau ntawmFais arc rauve steelmakingthiab ua qauv rau kev cog lus rau kev ua tau zoo thiab tus neeg siv khoom muaj txiaj ntsig.

Dab tsi yog qhov kev tawm tswv yim yav tom ntej rau graphite hluav taws xob hauv niaj hnub hluav taws xob tshuab hluav taws xob hlawv?

Yav tom ntej rauGraphite electrodesyog intrinsically txuas rau yav tom ntej ntawmFais arc rauve (EAF) steelmakingCov. Thiab lub neej yav tom ntej zoo li ci, tsav los ntawm ob peb lub txuj ci tseem ceeb.EAF Steelmakingyog feem ntau suav tias yog ntau cov neeg nyiam ib puag ncig tshaj li ib txwm muajmoj tej tawg ua kom sovcov kev, feem ntau vim nws muaj peev xwm siv feem pua ntawm covSeem Hlau Hlau, txo qhov xav tau rau cov khoom siv raw thiab qis dua co2 emissions ib tuj ntawmhlautsim tawm. Raws li ib puag ncig cov kev cai ua kom nruj thiab lub laub rau kev lag luam kev lag luam muaj zog, sib koom ntawmhlautsim ntawmEafsyuav tsum tau txuas ntxiv zuj zus ntxiv.

Qhov kev loj hlob no ncaj qha txhais los rau hauv kev txhawb nqa kev thov kom muaj txiaj ntsig zooGraphite electrodesCov. Ntxiv mus, cov qauv yog mus rau qhov loj dua, muaj zog duaFais arc rauv (Uhp rauv) kom ua tau zoo tshaj plaws tsim khoom thiab ua tau zoo. Tej noNiaj hnub nab hluav taws kub arc rauvyuav tsum tau nce zuj zusCov Hluav Taws Xobmuaj peev xwm tuav tau ntau dua currents thiab kev ntxhov siab, thawb cov tuam ntxhab nyiam peb kom txuas ntxiv thev naus laus ziscoek) thiab cov txheej txheem ntau lawm los txhim khokhoom siv hluav taws xobkev ua tau zoo - tshwj xeeb tsom rau cov hluav taws xob tsis kam, siab dua thermal poob siab kuj, thiab txo qisoxidationtus nqi.

Kev tshawb fawb tseem txuas ntxiv mus rau thaj chaw zoo li:

- Cov txheej txheem txheej txheem saum npoo:Txhim kho kev tiv thaiv kev tiv thaiv zoo dua los txo cov ntugoxidation, ib qho tseem ceeb hauvkhoom siv hluav taws xobTau noj.

- Tsim Tus Qauv Txheej Txheem:Txhim kho lubtxoj xovTsim thiab nipple khoom rau txawm tias qis dua kev tawm tsam thiab cov pob qij txha muaj zog.

- Lwm cov thev naus laus zis:ThaumnpaimCov tseem ceeb tshaj plaws, kev tshawb nrhiav tshawb nrhiav lwm txoj kev nqa khoom tam sim no, txawm hais tias tsis muaj kev sib tw tam sim nonpaim'S zuag qhia tag nrho cov khoom lag luam rau cov lojEafsCov. Ncaj qha tam sim no (Dc) lub tshuab ziab, feem ntau siv ib qho lojGraph kaw electrode, kuj sawv cev rau ntu ntawm kev ua lag luam nrog tshwj xeebkhoom siv hluav taws xobyuav tsum tau.

- Smart Rauv Kev Ua Haujlwm:Kev sib xyaw ua ke Sensor Technology thiab kabmob AI los ua kom zookhoom siv hluav taws xobkev cai, cov khoom siv hluav taws xob muaj zog, thiab twv seb cov teeb meem muaj peev xwm, yog li maximizingkhoom siv hluav taws xoblub neej thiabqho cubefficiency.

Xws listeelmakersMob siab rautsim cov hlau zoo hlauNtau dua thiab muaj kev cia siab, qhov kev thov rau kev txhim khu kev qha, kev ua tau zooGraphite electrodesyuav nyob ruaj khov. Peb, raws li cov tuam ntxhab, tau cog lus los ntsib qhov kev thov no los ntawm kev txhim kho txuas ntxiv thiab kev tsim kho tshiab, ua kom covkhoom siv hluav taws xobtseem muaj tus yuam sij uas muaj cov niaj hnubFais Arc Statmaking.

Tseem ceeb takaways:

- Graphite electrodesyog cov neeg tseem ceeb hauvFais arc rauv (EAF), coj tus cwj pwm siab los tsim ib qholub nkojuasMELTTS SEEM HLAU.

- Npaimyog cov khoom siv zoo tagnrho vim nws qhov siabqho kubKuj, zoo hluav taws xob conductivity, thermal poob siab kuj, thiab siab-kub lub zog.

- Cov Hluav Taws Xobtuaj hauv qib (RP, HP,Uhp) sib phim rauqho cublub hwj chim;UHP Electrodessiv rab koob hwm hwmcoekrau kev ua haujlwm siab tshaj plaws.

- Kev tsim khoom yog muaj complex, koom nrog kev sib xyaw, sib sau, ci,duab(thaum ~ 3000 ° C), thiab precision machining.

- Kev tswj kom zoo (tshuaj xyuas ntom ntom, tiv taus lub zog, qhov ntev, qhov tseem ceeb) yog qhov tseem ceeb rau kev ntseeg siabkhoom siv hluav taws xobkev ua tau zoo thiab paub txog kev noj haus hauvcua sov melt.

- Tsim nyog tuav, cia, thiab sib dhos ua ke sib dhos (huv si, muaj tseeb lub zog) yog qhov tseem ceeb heev los tiv thaivkhoom siv hluav taws xobkev puas tsuaj thiab ua haujlwm kom muaj txiaj ntsig zoo.

- Cov teeb meem tshwm sim suav nrog kev noj (oxidation, cov taub ploj), tawg (thermal / kev ntxhov siab ntawm txhua yam), thiab cov teeb meem sib koom ua ke; Mitigation Mitigation yuav muaj kev zooCov Hluav Taws Xobthiab kev khiav haujlwm ua haujlwm zoo.

- Xaiv ib tus neeg xa khoom yuav tsum ntsuas cov kws muaj kev txawj ntse, cov kev pab zoo, kev txhawb nqa kev pab, thiab txhua yam tus nqi - tsis yog nqe xwb. Saib rau pob tshab thiab kev ntseeg siab.

- Lub neej tom ntejEAF Steelmakingyog muaj zog, tsav tsheb txuas ntxiv thov thiab kev tsim kho tshiab hauvGraph kaw electrodethev naus laus zis rau lub zog siab dualub tshuab ziabthiab txhim kho kev ua tau zoo.

Lub Sijhawm Post: 04-18-2025