Graphite electrodes yog unsung Heroes ntawm niaj hnub steel ntau lawm, tshwj xeeb tshaj yog nyob hauv lubFais arc rauv(EAF). Cov no zoo li yooj yim sib xyaw ua si ibindispensable lub luag haujlwm, ua yeeb yam raws li kev conduit rau kev lojHluav Taws Xob Hluav Taws Xobxav tauyaj seemHlau Thiabua kom huvnws mus rau hauv cov hlau zoo. Nkag siab txog txoj haujlwm, hom, thiab qhov tseem ceeb ntawm lubGraph kaw electrodeyog qhov tseem ceeb rau leej twg koom nrogEAF Steelmaking, los ntawm cov ua haujlwm cub hluav taws zoo li Mark Tijloos kom muaj cov kws tshaj lij tshwj xeeb nrhiav txhim khu kev qha, cov ntaub ntawv ua tau zoo. Kab lus no ua ke mus rau hauv lub ntiaj teb ntawmGraphite hluav taws xob hauv hluav taws xob arctshuab hluav taws xob, tshawb nrhiav vim li cas lawv yog xws li aCRUCIANE TSEEM CEEB, lawv ua haujlwm li cas, cov qib sib txawv muaj nyob hauv (HpthiabUhp), thiab cov xwm txheej dab tsi kom ntseeg tau tias kev ua tau zoo thiab ua tau zoo hauv kev xav tauTxheej txheem stugmakingCov. Peb yuav tshawb vim li cas lawvHigh Txhua Yam Zogthiab cov khoom ntiag tug ua rau lawv tseem ceeb rau qhov noKev kub siabNtawv thov.

Dab tsi yog qhov hluav taws xob arc rauv taws (EAF) thiab nws txawv li cas ntawm cov txheej txheem?

IbFais arc rauv(EAF) sawv cev rau txoj kev nce qib tseem ceeb hauv cov txheej txheem ntau lawm piv rauCov txheej txheem ib txwm muajZoo li cov pa roj oxygen yooj yim (khau khiab) uas feem ntau sivHlau oreCov. Lub EAF yog qhov tseem ceeb ib tug loj heev, muaj zog melting lauj kaub uas sivHluav Taws Xob Hluav Taws XobTxhawm rau hloovseemHlau - xws li los ntawm cov tsheb qub thiab cov khoom siv rau kev lag luam tawm ntawm cov nyhav - mus rau hauv cov hlau tshiab. Tus txheej txheem no muaj ntau qhov zoo, tsis sib haum nws kev cia siab ntawm rov ua dua tshiabCov khoom siv raw (Seem Hlau Hlau), uas cuam tshuam ntau txoj kev ib puag ncig ib puag ncig piv rau kev tsuas thiab ua cov nkauj xwb hlau. EAF yog paub rau lawv yooj yim, pubsteelmakersLos tsim cov dav dav ntawm cov qib steel, suav nrog cov tshwj xeebhlausteels.

Cov tub ntxhais sib txawv nyob hauv lubZog Khoomthiab thawjCov khoom siv rawCov. Thaum cov kev ua hluav taws xob hluav taws xob ua kom sov rau cov tshuaj lom neeg coke thiab hlau ore ntawmQhov Kub Siablos tsim cov hlau nplaum (uas yog ua kom zoo rau hauv cov hlau), tusFais arc rauvsiv high-zogHluav taws xob tam sim no, xa los ntawmGraphite electrodes, rauTsim kom muaj cua sov- Peb tab tom tham txog kub txog li 1,800degrees Celsius(tshaj 3,000 Fahrenheit) thiab dhau mus - ncaj qha melting tus nqi themSeem HlauCov. Hom no feem ntau yog nrawm dua rau qee cov nplai thiab ua rau muaj losqis tsev cog khoomRoj pa roj, uaEAF Steelmakingib tug ntau ua neeg nyob rau hauvZUS TAU TEJ COV STEELnyob rau hauv ntau cov xwm txheej. Nws yog lub zog hluav taws xob ntawm kev rov ua dua tshiab, tig nag hmo rau hauv tag kis cov vaj tse.

Vim li cas thiaj li graphip electrode lub plawv ntawm EAF txheej txheem?

TusGraph kaw electrodeyog tiag tiag indispensable nyob rau hauv lubFais arc rauvCov. Yog tsis muaj nws, tag nrho cov txheej txheem tsuas yuav tsis ua haujlwm. Nws thawj txoj haujlwm yog coj los ua qhov lojHluav taws xob tam sim notsim nyog rauTsim muaj hluav taws xob arcnruab nrab ntawmkhoom siv hluav taws xobCov lus qhia thiab cov xim hlau ntxiv (seem) Sab hauv qhov cubCov. Nolub nkojyog lub hauv paus ntawm lubkhaus tshav kubyuav tsum tauyajtusSeem Hlau HlauCov. Xav txog tusGraph kaw electrodeRaws li lub ntsiab lus nyob rau hauv ib tug loj heev, super-powered lauj kaub, tab sis es tsis txhob rhaub dej, nws tau yaj ntawm cov hlau.Graphite hluav taws xob yog qhov tseem ceebVim tias lawv muaj ib qho tshwj xeeb ua ke ntawm cov khoom ntawm cov khoom haum rau cov chaw hnyav no.

Firstly, Gracite boasps delediblyKev Ua Hluav Taws Xob Kev Zoo Tshaj, tso cai rau nws los lis cov dej ntws khov (kaum tawm txhiab tus amperes) muaj txiaj ntsig nrog tsawgHluav Taws Xob Hluav Taws Xobpoob (tsis muaj kev tsis taus). Thib ob, nws muaj tshwj xeebthermalKuj thiabHigh Txhua Yam Zog, ua kom nws muswithstand cov huab cua sovthiab thermal poob siab tsim los ntawmFais arcThiab tusMolten SteelDa dej yam tsis muaj kev txwv tsis pub dhau los lossis tawg. Lwm cov ntaub ntawv yuav tsuas yog vaporize lossis huaj vam nyob rau hauv cov xwm txheej zoo li no. TusLub luag haujlwm ntawm Graphite Electrodestxuas ntxiv dhau ntawm kev ua hluav taws xob; Lawv yog cov neeg siv taukhoom siv hluav taws xobtshwj xeeb yog tsim rau cov kev xav tau ntawm covFais arc rauve steelmakingtxheej txheem. Lawv yog, tsis muaj exaggeration, lub luag haujlwm tseem ceeb ib puag ncig uas eaws ua haujlwm eff.

Graphite Electrodes ua haujlwm li cas nyob rau hauv hluav taws xob arc? (Tsom rau arc)

Khawv koob ntawmFais arc rauvtshwm sim thaum lubGraphite electrodesyog txo qis rau tus nqi ntawmSeem HlauCov. Lub siab-voltage, kev kub siabLub Hluav Taws Xob Tam Sim Noyog dhau los ntawmkhoom siv hluav taws xobsab. Raws li tuskhoom siv hluav taws xobCov lus qhia tau ze ntawm cov xim hlau ntxiv, cov huab cua sib txawv ntawm lawv ionizes, tsim kom muaj hluav taws xob kev tawm - covFais arcCov. Nolub nkojyog qhov tseem ceeb tswj kev tswj ntsia liaj qhov rooj ntawm xob laim, tso nyiaj tshaj tawm ntawm lub zog feem ntau hauv daim ntawv ntawmqho kubCov. TusCov txheej txheem hluav taws xob tam sim nolos ntawm ib qhokhoom siv hluav taws xob, dhau ntawmlub nkoj, rau hauvseem, muaj feem ntawm lwm tuslub nkojrau lwm tuskhoom siv hluav taws xob(Nyob ntawm qhov teeb tsa), ua tiav ntawm Circuit Court.

Tus txheej txheem no ntawmFais arcTsim yog txuas ntxiv mus rau lub sijhawm melting theem. Tuskhaus tshav kub(feem ntau tshaj 3000 ° CHauv hluav taws xob arcnws tus kheej) radiates mus rau hauvseem, sai sai ua rau nws musyajCov. TusCov Hluav Taws Xob Kev Coj Uatsis yogTam sim no mus rau hauv qhov cub cua sov, tab sis kuj tswj lublub nkoj'S kev ruaj khov thiab txoj hauj lwm kom ntseeg tau tias muaj txiaj ntsig. Kev tswj cov tshuab tswj kev nruj heev hloov kho txoj haujlwm ntawm lubkhoom siv hluav taws xobTxhua tas li kom los saib xyuas qhov zoo tshaj plawslub nkojNtev thiab lub zog tawm tswv yim. Nws yog qhov no tswj, muaj zoglub nkoj, yooj yim los ntawm resilientGraph kaw electrode, uas ua rau lub hauv paus ntawmKUB KOMnyob rau hauvFais arc rauv, ua rau kev hloov pauv ntawm cov khoomseemmus hauvMolten Hlau.

Dab tsi yog cov haujlwm tseem ceeb ntawm graphite hluav taws xob hauv EAF steelmaking?

TusKev ua haujlwm ntawm Graphite EctrodesHauv ibFais arc rauvyog multifaceted thiab tseem ceeb rau kev ua tiavKev Ua Haujlwm Ua HaujlwmCov. Thaum lub sijhawm ua haujlwm tseem ceeb yog cov paub zoo, ob peb lub luag hauj lwm tseem ceeb tau hais txog lawv qhov tseem ceeb:

- Ua cov hluav taws xob tam sim no:Qhov no yog qhov muaj nuj nqi tshaj plaws. Tuskhoom siv hluav taws xobua raws li txoj kev rau qhov loj heevHluav taws xob tam sim noxav tau rau hwj chim lub cub tawg. Lawv liKev Ua Hluav Taws Xob Kev Zoo Tshajua kom muaj qhov no tshwm sim zoo.

- Ua kom muaj suab Arc:Tuskhoom siv hluav taws xobCov lus qhia yog tshwj xeeb nyob qhov twgFais arcraug ntaus. Lawv yuav tsum tiv thaiv lubhuab cua sov heevthiab erosive rog ntawm lublub nkojnws tus kheej rauTsim kom muaj cua sovxwm yeem. Lub peev xwm ntawmgraphite electrodes los tsimnokub tsim nyog rau yajtusseemyog qhov tseem ceeb.

- Hloov pauv cua sov:Tusqho kubgenerated los ntawmlub nkojyog pauv mus rauseemthem feem ntau ntawm hluav taws xob. Tuskhoom siv hluav taws xobS txoj hauj lwm thiab tuslub nkojstability cuam tshuam li cas zoo li noqho kubHloov pauv tshwm sim, cuam tshuam ncaj qha melting ceev thiab kev siv zog.

- Cov xwm txheej hnyav:Tuskhoom siv hluav taws xobyuav tsum muaj kev txom nyem tsis yogQhov Kub Siabntawm lublub nkojthiabMolten Steeltab sis kuj tshuaj tua neeg tawm tsam los ntawmnpleem(Molten impurities) thiab kev ntxhov siab lub cev thaum lub sijhawm ua haujlwm (zoo li muaj peev xwmseemLub qhov tsua-ins). Lawv lithermalkev ruaj khov thiabHigh Txhua Yam Zogyog tseem ceeb heev ntawm no.

- Pab Txhawb Nqa Cov Lus Qhia:Thaum melting yog tus yuam sij, tuslub nkojkuj ua lub luag haujlwm hauv lubua kom huvtheem, pab kom tshem tawm impurities thiab kho cov chemistry ntawm lubMolten Steellos ntawm kev tswj hwmqho kubCov tswv yim thiab cov teebmeem kev cuam tshuam rau covlub nkoj.

Nyob rau hauv essence, tusGraph kaw electrodeTsis yog xaim xwb; Nws yog lub cuab yeej siab-ua tau zoo dua kom xa lub zog, tsim lub suablub nkoj, thiab muaj sia nyob ib qho ntawm cov chaw muaj kev lag luam heev hauv ntiaj teb. TusCov Hluav Taws Xob Hauv Fais Arc Rauvkev ua haujlwm yog cov haujlwm ua haujlwm tiag tiag uasMELT STEEL.

Dab tsi mus rau hauv kev ua kev ua haujlwm zoo graphite electrode? (Cov ntaub ntawv raw thiab kev tsim khoom)

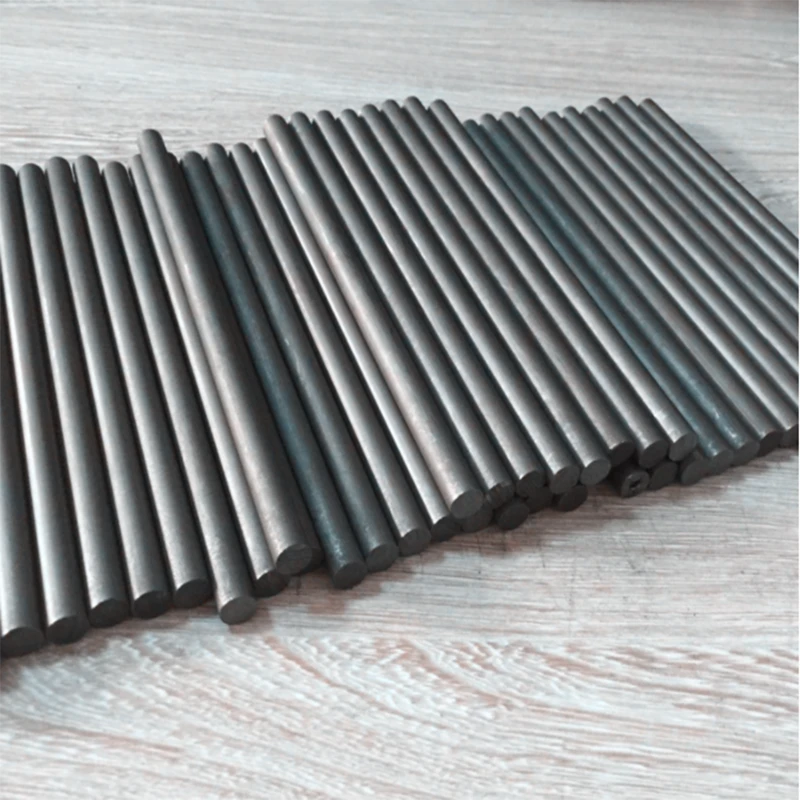

Tsim ibGraph kaw electrodemuaj peev xwm ua tau raws li hauvFais arc rauvyog ib txoj kev ua, ntau theem kev ua haujlwm koom nrog kev xaiv zooCov Khoom Siv Rawthiab cov txuj tsim khoom lag luam zoo. Cov khoom xyaw uas tseem muaj txiaj ntsig zooRoj av cokethiabKoob coke. Koob coke, nrog nws cov crystalline zoo, rab koob-nyiam qauv, yog tshwj xeeb yog qhov tseem ceeb rau kev ua tau zooCov Hluav Taws Xob(tshwj xeeb yogUHP Graphiteelectrodes) vim tias nws muab tau zoo heevHluav Taws Xob Kev Tshaj Tawm, Tsawg thermal nthuav dav, thiab zoo dua mus rau lub thermal poob siab thiaboxidation.

Cov txheej txheem feem ntau cuam tshuam:

- Nws:Ntsuas ntsuas cov nyiaj tau los ntawm cov calcinedRoj av coke, Koob coke, thiab lub pob zeb ntim cov ntaub thee yog sib xyaw ua ke ntawm cov chaw kub.

- Txoj kev sib sau (extrusion lossis molding):Qhov sib tov yog tom qab ntawd tsim rau hauv cov ntawv cylindricrical ntawm covkhoom siv hluav taws xob, feem ntau dhau los ntawm extrusion rau cov qauv ntau thiab tsawg.

- Ci:Tus "ntsuab"khoom siv hluav taws xobyog maj mam ci nyob rau hauv lub cub hluav taws loj ntau tshaj li ntau lub lim tiam rau carbonize lub binder thiab tsim cov qauv carbon.

- Impregnation:Kom nce ntom ntom, lub zog, thiab conductivity, lub cikhoom siv hluav taws xobFeem ntau impregnated nrog pitch nyob rau hauv siab thiab ces rov qab. Cov kauj ruam no yuav rov ua dua.

- Graphitizitizitization:Nov yog ib qib tseem ceeb. Tuskhoom siv hluav taws xobyog rhuab rau heevKev Kub Siab(Mus txog 3000degrees Celsius) Hauv lub cub hluav taws xob tshwj xeeb. Noduabcov txheej txheem txiav txim rau cov pa roj carbon atoms rau hauv kev txiav txim crystalline qauv ntawm cov khoom xav tau xws li cov haujlwm uas xav tau thiabthermal KujCov. TusCov ntsuas kubyog ua tib zoo tswj tau.

- Machining:Thaum kawg, cov graphitizedkhoom siv hluav taws xobyog precision-machined los tsim cov sab hauv cov sab hauv ntawm qhov xaus, cia tus neegkhoom siv hluav taws xobcov tshooj yuav tsum tau koom nrog ua ke rau hauv cov kab ntawv ntev rau kev siv hauvEafs.

Qhov kev tsis txaus ntseeg no ua kom kawgGraph kaw electrodemuaj cov yam ntxwv tsim nyog -Kev tiv thaiv qis, siab ntom, zoo heevNeeg Kho Tshuab Muaj Zog, thiab muaj peev xwm ua raws li kev rau tximSab hauv qhov cubCov. Ua tus tswv tsev nrog 7 cov kab ntau lawm, I, Allen, tuaj yeem ua kom pom qhov xav tau qhov uas xav tau ntawm txhua kauj ruamtsim cov hlau zoo hlauCheebtsam zoo li no.

Kev txiav txim siab cov hom graphite hluav taws xob: RP, HP, thiab UHP piav qhia

Tsis yog txhua tusGraphite electrodesyog tsim sib npaug. Lawv feem ntau tau cais rau hauvPeb homraws li lawv cov khoom thiab cov qib fais fab lawv tau tsim los tswj hwm hauvFais arc rauvCov. Nkag siab cov qib no yog qhov tseem ceeb rau kev sib txuamkhoom siv hluav taws xobrau qhov tshwj xeebHom rauvthiab kev ua haujlwm ua haujlwm.

-

Lub zog tsis tu ncua (RP) graphite electrode:

- Cov Khoom Siv Raw:Feem ntau ua los ntawm cov qauv-qib calcinedRoj av coke.

- Ceev tam sim no:Tsim los rau qis duaceev ceevCov ntawv thov (feem ntau <18 a / cmo).

- Cov Ntawv Thov:Siv hauv me dua lossis laus duaEafs, feem ntau rau melting yooj yimSeem Hlau Hlaulossis hauvLable Furnacesrau kev ua kom zoo, thiab qee zaum hauvSubmerged arcFurnaces rau ferrroalloy ntau lawm. Peb liLub Zog Hluav Taws Xob Kaw Lusyog tsim nyog rau cov ntawv thov no.

- Cov yam ntxwv:Tus nqi qis dua, muaj zog nruab nrab thiab kev coj ua piv rau cov qhab nia siab dua. IbRp graphite electrodeyog cov kev xaiv nkag-qib.

-

Muaj Zog Muaj Zog (HP) Graphite Electrode:

- Cov Khoom Siv Raw:Siv ntau dua calcinedRoj av coke, qee zaum nrog ib feem ntawmKoob coke.

- Ceev tam sim no:Haum rau siab duaceev ceevCov haujlwm (feem ntau 18-25 A / CM²).

- Cov Ntawv Thov:Siv hauv nruab nrab rau cov peev xwm lojEafsrauTxheej txheem stugmakingyuav tsum tau nrawm melting lub sijhawm tshaj li rp tso cai.

- Cov yam ntxwv:Muaj zoo duaHluav Taws Xob Kev Tshaj Tawm, thermal Kuj, thiabNeeg Kho Tshuab Muaj ZogduaKheejCov electrodes. Kev xaiv txhim khu kev qha rau ntau tus qauvEafsCov. Txheeb xyuas pebHigh-fais fab graphite electrodekev xaiv.

-

Ultra-siab zog (UHP) graphite electrode:

- Cov Khoom Siv Raw:Feem ntau ua los ntawm hwmKoob coke.

- Ceev tam sim no:Tsim los rau cov ntawv thov xav tau ntau tshaj plaws nrog ntau heevceev ceev(> 25 a / cmo).

- Cov Ntawv Thov:Qhov tseem ceeb rau niaj hnub, muaj kev tsim khoom zooEafsAiming rau cov zis tshaj plaws thiab ua tau zoo. Siv rauyajZoo tagnrho ntawmseemsai sai.

- Cov yam ntxwv:Zoo tshajHluav Taws Xob Kev Tshaj Tawm (Kev tiv thaiv qis), zoo heev tiv taus rau cua sov thiaboxidation, siab tshaj plawsNeeg Kho Tshuab Muaj Zog. UHP GraphiteCov hluav taws xob tso cai ua kom cov cub hluav taws los ua haujlwm ntawm cov zog hluav taws xob ntau ntau, txo cov kais-to-kais lub sij hawm. Peb HwmUltra-Siab Fais Fab Graphite Hluav Taws Xobyog engineered rau cov haujlwm xav tau no.

Xaiv qhov tseebkhoom siv hluav taws xobHom (Kheej, Hp, lossisUhp) tseem ceeb heev rau kev ua kom tau zooKev Ua Haujlwm Ua Haujlwm, Tswj kev siv zog hluav taws xob, thiab tswj cov nqi ntau heev. Siv ib qhokhoom siv hluav taws xobTsis tso cai rau lub cub hluav taws xob lub zog tuaj yeem ua rau thaum ntxov ua tsis tau thiab lub zog.

Qhov zoo ntawm qhov hluav taws xob cuam tshuam EAF kev ua haujlwm EAF kev ua tau zoo li cas thiab tag nrho cov nqi?

Qhov zoo tshaj ntawm lubGraph kaw electrodesiv nyob rau hauv ibFais arc rauvMuaj qhov cuam tshuam ncaj qha thiab tseem ceeb rau ob qho tib si kev ua tau zoo ntawm cov cua cub thiab tag nrho cov nqi ntawm cov steel ntau lawm. Rau cov tub ceev xwm muaj txiaj ntsig zoo li Marompson, nkag siab qhov txuas no yog tus yuam sij rau kev txiav txim siab them tus nqi uas tsis ua haujlwm zoo. Qis-zooCov Hluav Taws Xobtej zaum yuav zoo li pheej yig dua uper, tab sis lawv feem ntau ua rau cov nqi siab dua tag nrho vim muaj kev nce qib ntxiv), siv sijhawm qis dua lossis tsis muaj peev xwm cuam tshuam.

Siab zooGraphite electrodes, tus cwj pwm los ntawm cov qauv coj ua qauv, siab ntom,Kev tiv thaiv qis, zoo heevthermalpoob siab kuj, thiabHigh Txhua Yam Zog, pab rau:

- Txo electrode kev noj:Lawv withstand covhuab cua sov heevthiab lwm yam kev ntxhov siab zoo dua, ua rau ntev duaKev Pabcuam Lub NeejThiab tsawg dua graphite tau noj ib tuj ntawm cov hlau tsim tawm.

- Txhim Kho Zog Ua Haujlwm:Zoo duaHluav Taws Xob Kev Tshaj Tawmtxhais tau tias tsawgHluav Taws Xob Hluav Taws Xobyog nkim liqho kubnyob rau hauv lubkhoom siv hluav taws xobnws tus kheej, tso cai rau lub zog ntau kom ncav cuaglub nkojthiabyajtusseemSai.

- Nce tsim khoom:Lub nkuajlub nkojkev ua tau zoo thiab txo qis qis vim yogkhoom siv hluav taws xobBreakage lossis kev ua tiav ntxov ua rau cov kais luv luv-rau-kais lub sij hawm thiab ntau dua rhuab zis.

- Txo kev pheej hmoo ntawm tawg:Zoo tshajNeeg Kho Tshuab Muaj Zogtsawg kawg kev pheej hmoo ntawmkhoom siv hluav taws xobTxhua qhov tawg thaum lub sijhawm ua haujlwm, uas tuaj yeem ua rau muaj nqi qeeb thiab muaj peev xwm rauv puas tsuaj.

- Kev ua tau zoo ib yam:Vam tauCov Hluav Taws Xobmuab cov kev coj tus cwjpwm tsis tau, tso cai rau cov txheej txheem tswj tau zoo thiab pabtsim cov hlau zoo hlauxwm yeem.

Hloov pauv, tsis sib haum lossis tsis muaj txiaj ntsig zooCov Hluav Taws Xobtuaj yeem ua rau muaj kev sib tsoo nquag, kev siv hluav taws xob siab dua, tsis muaj peev xwm ua rau cov voj voog uas tsis tau paub, thiab nce ntxivtxoj hmabCov teeb meem, thaum kawg tsav tus nqi ib tuj ntawm cov hlau. Yog li ntawd, nqis peev zooGraphite electrodesyog qhov tseem ceeb rau kev ua tau zoo thiab nyiaj txiagEAF Steelmaking.

Cov teeb meem loj twg ua rau muaj statalmakers ntsib nrog graphite electrodes hauv EAF kev ua haujlwm?

Kev khiav hauj lwm ibFais arc rauvlos nrog cov kev cov nyom, thiab ob peb ntawm cov no rov qab ncaj qha rauGraphite electrodesCov. Steelmakers thiab cov taws ua haujlwm tas li siv zog rau kev txo cov teeb meem no kom ntseeg tau tias du thiab ntau lawm. Ib qho kev sib tw loj yogkev noj electrode. Graphite hluav taws xob yog sivnce thaum lub sijhawm cov txheej txheem los ntawm cov lus qhia sublimation (vaporization vim yog tuslub nkojSkhaus tshav kub), saum npoooxidation(reacting nrog huab cua thiab cua sov roj), thiab cov tshuab tawg lossis npuaj. Tswj thiab txo qis kev noj haus no yog qhov tseem ceeb rau kev tswj hwm tus nqi.

Lwm qhov kev sib tw tseem ceeb, feem ntau yog qhov mob me me rau cov neeg yuav khoom xws li Mark, yog kom ua tiavkhoom siv hluav taws xobzoo thiab ntseeg tau. Kev hloov pauv hauvkhoom siv hluav taws xobcov khoom tuaj yeem ua rau muaj kev ua tau zoo tsis txaus ntseeg, tsis ruaj khovlub nkojkev coj cwj pwm, thiab muaj kev pheej hmoo ua txhaum. Qhov no nkag rau qhov tseem ceeb ntawm kev so los ntawm cov npe nrov uas muaj zog tswj hwm kev tswj hwm. Tuav thiab koom nrogkhoom siv hluav taws xobntu kuj yuav tsum tau saib xyuas; Kev sib koom tes tsis zoo tuaj yeem ua rau hluav taws xob kub tsis kam ntawm kev sib txuas, tsim kom ntau tshajqho kubthiab muaj peev xwm ua rau kev ua haujlwm tsis ua haujlwm lossiskhoom siv hluav taws xobbreakage. Tsis tas li ntawd,khoom siv hluav taws xobKev tawg thaum ua haujlwm yog mob taub hau loj, ua rau lub zog tseem ceeb, muaj peev xwm ua kev puas tsuaj rau lub cub tawg, thiab ploj ntawm kev tsim khoom. Thaum kawg, Lag luam nqe tsis qhib siab rauGraphite electrodes, tsav los ntawmCov khoom siv rawnqi (tshwj xeeb yogKoob coke) thiab cov khoom siv thoob ntiaj teb / Xav tau, ntxiv rau lwm txheej ntawm kev nyuaj rau kev coj mus ua thiab tus nqi tswj hwm rauEafs.

Raws li tus neeg yuav khoom (zoo li Mark), yuav ua li cas koj thiaj li paub tias koj tau txais txiaj ntsig txhim khu kev qha thiab zoo graphite electrodes?

Rau cov tswv lag luam thiab cov tub ceev xwm ua rau cov tub ceev xwm zoo li Markpson, tab tom ntseeg tau, muaj txiaj ntsig zooGraphite electrodesyog paramount. Muab cov ntsiab lus mob uas muaj peev xwm ua tau zoo, xa khoom noj qeeb, thiab muaj cov teeb meem tseem ceeb, ib txoj kev xaiv tswv yim thiab ntawv pov thawj yog qhov tseem ceeb. Ntawm no yog cov kauj ruam tseem ceeb yuav khoom:

- Nyem cov khoom xa khoom siv:Tsis txhob cia siab rau nqe. Tshawb nrhiav cov neeg xa khoom muaj peev xwm. Saib kom tsim cov chaw ua haujlwm nrog cov ntaub ntawv pov thawj ua pov thawj, zoo li peb lub tsev nyob hauv Suav teb nrog 7 kab ntau lawm. Tshawb xyuas lawv cov kev paub, cov kev lag luam nthuav tawm tseem ceeb (Tebchaws Europe, thiab lwm yam. Qhia rau cov qauv kev paub thoob ntiaj teb), thiab muaj peev xwm ntau lawm.

- Thov cov ntawv pov thawj thiab ntawv ceeb toom:Nug kom cov ncauj lus kom ntxaws, cov ntawv qhia tshuaj xyuas, thiab cov ntawv pov thawj tsom xam (E.G., ISO 9001 rau kev tswj hwm zoo). Thaum lub sij hawm ceev faj tawm tsam kev dag ntxias yog xav tau, raws li cov chaw muag khoom tau muab cov ntaub ntawv zoo rau lawvkhoom siv hluav taws xobCov khoom lag luam. Nug tej yam tsis sib xws.

- Nkag siab txog cov qib (RP, HP, UHP):Xyuas kom meej tus xa khoom kom meej meej ntawmCov Hom Tshuaj Graphite Hluav Taws Xobthiab tuaj yeem muab qib tshwj xeeb (HplossisUhp) Yuav tsum tau kojFais arc rauvCov. Sib tham txog tusCov khoom siv rawlub hauv paus (piv txwv li, feem ntawmKoob cokerauUHP Graphite).

- Nug txog kev tswj kom zoo:Nug txog lawv cov lej QC thoob plaws kev tsim khoom - los ntawmCov khoom siv rawtshuaj xyuas rauduabTswj thiab zaum kawgkhoom siv hluav taws xobMachining thiab kuaj. Lawv yuav ua li cas kom paub tseeb?

- Tham txog Logistics thiab Leades Lub sij hawm:Kom meej meej qhia koj lub sijhawm uas yuav tsum tau txais. Cov chaw muag khoom kom nkag siab txog kev cuam tshuam txog kev cuam tshuam txog kev qeeb thiab yuav tsum muab cov kev npaj ua kom zoo thiab muaj kev thauj khoom ruaj khov. Chaw nyob cov teeb meem kev thauj khoom uas muaj peev xwm ua tau.

- Nrhiav cov ntawv pov thawj lossis cov ntaub ntawv kawm:Cov npe nrov feem ntau muaj cov lus tim khawv lossis cov ntaub ntawv kawm los ntawm cov neeg siv khoom txaus siab, feem ntau txawm nyob hauv koj thaj av (Tebchaws Asmeskas, North America, Europe).

- Xav txog lub Hoobkas kuaj lossis tshuaj ntsuam thib peb:Rau kev yuav khoom tseem ceeb lossis cov khoom siv xa khoom tshiab, npaj kev tshuaj xyuas lossis kev tshuaj xyuas ua ntej ua ntej tuaj yeem muab cov kev paub ntxiv thiab cov txheej txheem zoo.

- Tsim kev sib raug zoo:Qhib kev sib txuas lus yog qhov tseem ceeb. Ua haujlwm nrog cov neeg muab khoom siv, pob tshab, thiab txaus siab nkag siab koj cov kev xav tau tshwj xeeb hais txogGraphite electrodes hauv EAF. Raws li Allen, Kuv ua ntej meej kev sib txuas lus nrog cov neeg siv zoo li Mark.

Los ntawm kev coj cov kauj ruam no, cov neeg yuav khoom tuaj yeem txhim kho lawv txoj kev pheej hmoo ntawm kev ua tau zooCov hluav taws xob siv hauv EAFKev ua haujlwm, kev pheej hmoo tsawg thiab ua kom muaj kev ua kom sov txhim kho. Cov khoom lag luam zoo li pebConductive Graphite Qws Rau Cov Hluav Taws XobthiabHigh-zog graphite blocksXav txog peb kev cog lus rau cov ntaub ntawv zoo.

Saib tom ntej: Qhov kev hloov zuj zus ntawm graphite electrodes nyob rau hauv sustainable steel ntau lawm

TusFais arc rauvtxoj kev, hnyav tshaj plaws rauGraphite electrodes, yog twb yog lub hauv paus ntawm cov hlau ntsuab ntau lawm vim nws lub peev xwm rov qab ua dua tshiabSeem Hlau HlauCov. Raws li lub ntiaj teb thawb rau kev ua kom ruaj khov, tusLub luag haujlwm ntawm Graphite ElectrodesthiabEAF Steelmakingyog teem los ua qhov tseem ceeb tshaj. Kev tsim kho yav tom ntej yuav ua rau muaj kev txhim kho ntxiv thiab txo qhov kev cuam tshuam ib puag ncig ntawm cov txheej txheem no. Qhov no suav nrog kev tshawb fawb txuas mus rau hauvkhoom siv hluav taws xobcov ntaub ntawv thiab tsho tiv no kom txo qisoxidationthiab txo cov nqi ua haujlwm tshwj xeeb thiab kev siv tau.

Tsis tas li ntawd, kev hloov tshiab hauvEafthev naus laus zis, xws li kev txhim kho cov txheej txheem tswj, txhim kho lub zog hluav taws xob rov qab, thiab cov peev txheej ntawm kev siv txuas ntxiv mus txuas ntxivHluav Taws Xob Hluav Taws XobQhov chaw rau lub zoglub nkoj, yuav ua tiav kev nce qib hauvkhoom siv hluav taws xobthev naus laus zis. Lub tsav mus rau siab duaceev ceevKev ua haujlwm los ua haujlwm kom ua tau zoo tshaj plaws uas yuav xav tau kev txhim kho hauvUHP Graphite khoom siv hluav taws xobzoo, tshwj xeeb heev txogthermalpoob siab tsis kam thiabNeeg Kho Tshuab Muaj ZogCov. Raws li peb tsiv mus rau tom ntej, lub synergy ntawm qhov chaw rauv yooj yim thiab ua tau zooGraphite electrodesyuav yog qhov tseem ceeb heev nyob rau hauv kev ua steel ntau lawm, txo kev cia siab rauTsoos cov cub tawg, thiab ua rau muaj kev lag luam zoo nkaujSeem HlauCov. Tus txo hwj chimGraph kaw electrodeyuav nyob twj ywm tsis muaj feem tiv thaiv yav tom ntejNiaj hnub nimno hlau.

Tseem ceeb takaways: graphite electrodes hauv eaF steelmaking

- IndisPensable tivthaiv: Graphite electrodesyog qhov tseem ceeb rauFais arc rauv(EAF) kev ua haujlwm, coj tusLub Hluav Taws Xob Tam Sim Noxav tauTsim muaj hluav taws xob arcthiabyaj seemHlau.

- Cov khoom muaj cim:Graphite yog xaiv rau nws qhov siabHluav Taws Xob Kev Tshaj Tawm, tshwj xeebthermal Kujrauwithstand cov huab cua sov, thiabHigh Txhua Yam ZogYuav tsum muaj nyob rau hauv thaj chaw ERSH EAF.

- Yuav ua li cas lawv ua haujlwm: Cov Hluav Taws Xobnqa siabTam sim no hlalos tsim ib qholub nkojnruab nrab ntawmkhoom siv hluav taws xobntsis thiab tusseem, tsim khoomkhaus tshav kubrau melting.

- Hom Teeb Meem: Cov Hluav Taws Xobtuaj hauv qib -Lub zog tsis tu ncua (RP), Muaj Zog Muaj Zog (HP), thiabUltra-Siab Fais Fab (UHP)- raws liCov Khoom Siv Raw (Roj av coke, Koob coke) thiabceev ceevmuaj peev xwm. Txuam raukhoom siv hluav taws xobNtaus rau lub cub tawg yog qhov tseem ceeb heev.

- Cov nqi cuam tshuam zoo nqi:Siab zooGraphite electrodesUa rau kev noj qis dua, lub zog zoo dua, muaj kev tsim txiaj ntxiv, thiab txo cov kev pheej hmoo ua haujlwm ntau dua piv rau cov kev xaiv qis dua.

- Sourcing khub:Cov neeg yuav khoom yuav tsum raug cov neeg yuav khoom kom huv si, txheeb xyuas cov ntawv pov thawj, nkag siab txog qib electrode, nug txog QC, thiab sib tham txog logistics kom ntseeg tau tias yuav ntseeg tau meej sourcing.

- EAF yog Greener: EAF Steelmaking, powered byGraphite electrodes, plays lub luag haujlwm tseem ceeb hauv kev rov ua dua tshiabSeem Hlau Hlauthiab muaj ntau txoj kev xaiv mus rauCov txheej txheem ib txwm muaj.

- Kev tsom xam yav tom ntej:Txuas ntxiv txhim kho lub hom phiaj los txhim khokhoom siv hluav taws xobefficiency (txo qis, kev ua tau zoo dua) thiab ua ke nrog kev nce qib hauv kev siv EAF siab thev naus laus zis.

Sijhawm Post: 05-0625