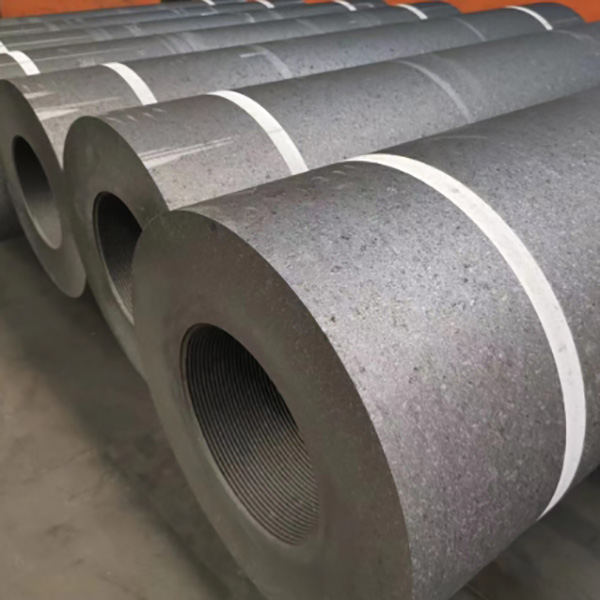

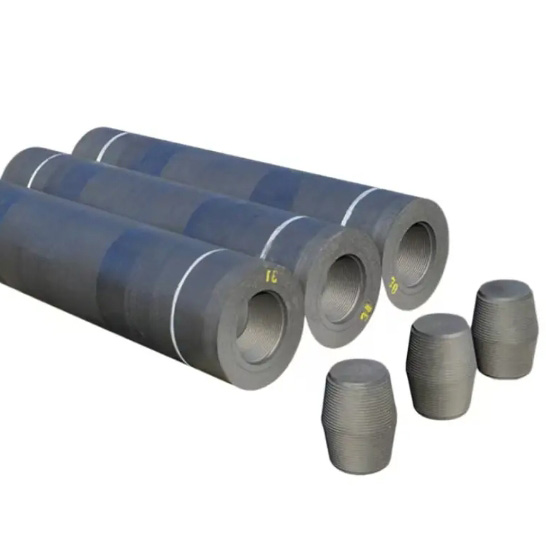

High Purity Graphite Block

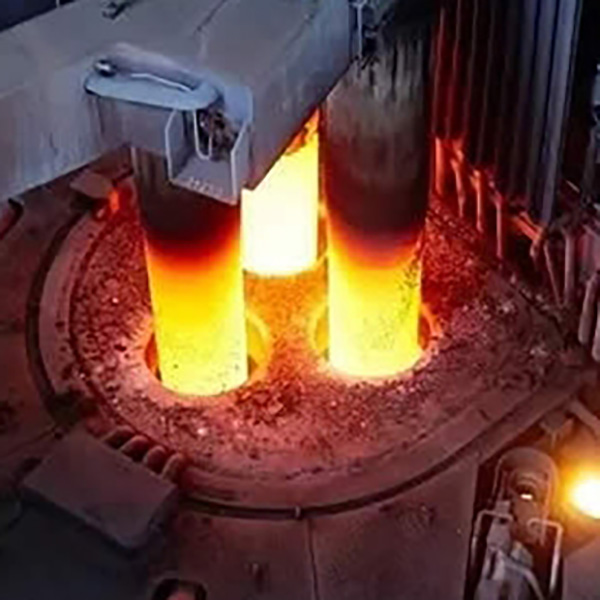

A high purity graphite block is a precision-engineered carbon product made from premium raw materials such as petroleum coke and pitch, then processed through high-temperature graphitization (up to 3000°C). With a typical carbon content of ≥ 99.9%, these blocks are designed for applications requiring ultra-low contamination, high thermal conductivity, and excellent chemical resistance.

High purity graphite blocks are essential in semiconductor manufacturing, solar photovoltaics, metallurgy, EDM machining, and high-temperature processing environments.

Key Features:

-

Ultra-High Carbon Content: Purity ≥ 99.9%, suitable for demanding cleanroom and high-vacuum environments

-

Outstanding Thermal Stability: Maintains structural integrity at temperatures exceeding 2500–3000°C in inert atmospheres

-

Chemical Resistance: Inert to most acids, alkalis, and corrosive gases under controlled conditions

-

Low Outgassing: Ideal for vacuum furnace parts, crystal growth, and aerospace tooling

-

Excellent Machinability: Easily shaped into custom parts and complex geometries with tight tolerances

Typical Applications:

-

Semiconductor Industry: Wafer boat carriers, susceptor plates, and diffusion trays

-

Solar Energy (Photovoltaics): Crucibles, insulation, and processing plates for mono- or poly-silicon growth

-

High-Temperature Furnaces: Fixtures, heating elements, and insulation blocks

-

EDM Electrodes: Used for precision mold making where material purity and surface finish are critical

-

Laboratory & Scientific Use: Sample holders, reaction vessels, and analytical instruments

Technical Specifications (Typical):

| Property | Value Range |

|---|---|

| Carbon Purity | ≥ 99.9% (can be up to 99.999%) |

| Bulk Density | 1.70 – 1.90 g/cm³ |

| Electrical Resistivity | 8 – 12 µΩ·m |

| Compressive Strength | 60 – 130 MPa |

| Flexural Strength | 20 – 55 MPa |

| Thermal Conductivity | 100 – 170 W/m·K |

| Ash Content | ≤ 0.03% (ultra-low impurity) |

| Operating Temp. Limit | Up to 3000°C (in inert/vacuum) |

Available Grades:

-

Purified Graphite (≥99.9%) – for standard high-purity applications

-

Ultra-High Purity Graphite (≥99.99% or ≥99.999%) – for semiconductors and ultra-clean processing

-

Isotropic or Fine Grain Options – for consistent strength and uniformity in machining

Standard Sizes & Customization:

-

Block Sizes: 300×300×100 mm, 400×400×200 mm, 600×600×300 mm, or per specification

-

Custom Machining: CNC services available for precision parts and graphite tooling

Packaging & Storage:

-

Vacuum-sealed or foam-protected packaging to prevent contamination

-

Store in dry, clean, and controlled environments