High power graphite electrode

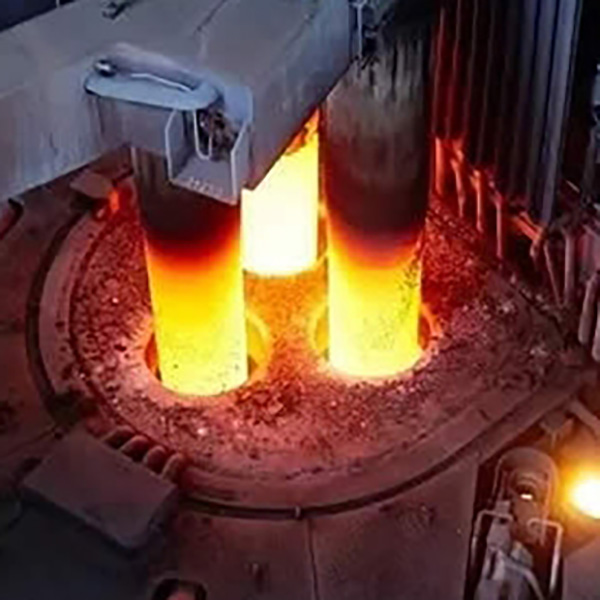

High Power (HP) Graphite Electrodes are precision-engineered carbon electrodes designed for use in electric arc furnaces (EAFs) and ladle furnaces (LFs) operating under medium-to-high electrical loads. Produced using high-grade petroleum coke and coal tar pitch, HP electrodes undergo multiple cycles of baking and graphitization at up to 2800°C, resulting in enhanced thermal conductivity, mechanical strength, and oxidation resistance compared to regular power electrodes.

They are ideal for steel mills and foundries seeking reliable performance with optimized cost-efficiency in electric furnace applications.

Key Features:

-

Moderate to High Electrical Conductivity: Delivers efficient arc performance with stable current flow

-

Good Thermal Shock Resistance: Capable of withstanding high-temperature fluctuations in the furnace

-

Improved Mechanical Strength: Reduced risk of electrode breakage or deformation

-

Low Ash and Impurity Content: Ensures minimal contamination of molten steel

-

Cost-Effective Alternative: Suitable for operations not requiring the extreme performance of UHP electrodes

Typical Applications:

-

Electric Arc Furnaces (EAFs): For carbon steel and alloy steel production

-

Ladle Furnaces (LFs): For refining, alloying, and desulfurization processes

-

Submerged Arc Furnaces: For non-ferrous alloy production and mineral smelting

-

Foundry Operations: Ideal for small to medium furnace capacities

Technical Specifications (Typical):

| Property | HP Grade Value |

|---|---|

| Bulk Density | ≥ 1.65 g/cm³ |

| Electrical Resistivity | ≤ 6.0 µΩ·m |

| Flexural Strength | ≥ 10.0 MPa |

| Elastic Modulus | ≤ 12 GPa |

| Thermal Conductivity | ≥ 120 W/m·K |

| Ash Content | ≤ 0.3% |

| Apparent Porosity | ≤ 23% |

| Current Carrying Capacity | 15,000 – 35,000 A (varies by size) |

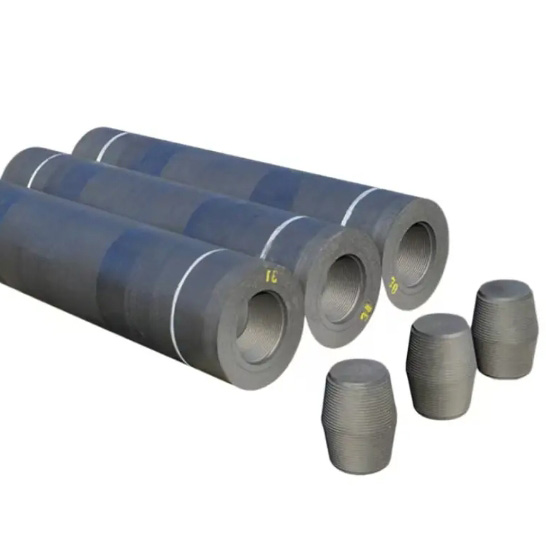

Available Sizes:

-

Diameter: 200 mm (8″) to 600 mm (24″)

-

Length: 1600 mm to 2400 mm

-

Nipple Types: 3TPI or 4TPI threading; custom threads available

-

Packaging: Wooden crates with anti-collision foam and moisture protection

HP vs UHP Electrodes:

| Feature | HP Electrode | UHP Electrode |

|---|---|---|

| Raw Material | Petroleum coke | Needle coke |

| Resistivity | ≤ 6.0 µΩ·m | ≤ 5.5 µΩ·m |

| Max Current Capacity | Up to 35,000 A | Up to 45,000 A |

| Cost | More economical | Higher investment |

Conclusion:

High Power graphite electrodes strike a balance between performance and cost, making them ideal for medium-duty electric furnace operations in steelmaking and metallurgical industries. With solid conductivity, strength, and stability, HP electrodes are a reliable choice for consistent and efficient production.