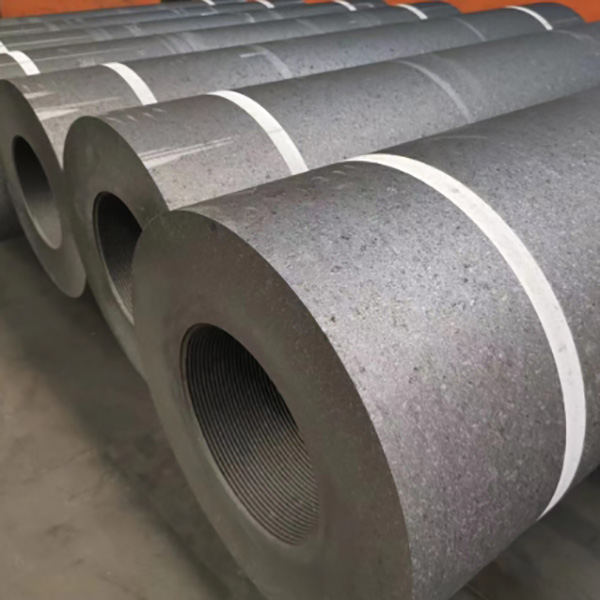

Graphite Welding Electrodes

Graphite welding electrodes are specialized non-consumable or semi-consumable electrodes made from high-purity carbon or graphite. They are used in arc gouging, cutting, and joining applications where high thermal resistance, stable arc performance, and low contamination are essential.

These electrodes are especially effective in air carbon arc cutting (CAC-A), a process that removes metal by melting it with an electric arc and blowing it away with compressed air.

Key Features:

-

High Thermal Resistance: Withstands temperatures over 3500°C without melting.

-

Excellent Electrical Conductivity: Maintains a stable arc for precise and consistent performance.

-

Low Contamination: Minimal impurities ensure clean weld zones with no unwanted chemical reactions.

-

Smooth Arc Operation: Produces uniform arcs with minimal spatter or resistance.

-

Durable and Long-Lasting: Offers extended life even in aggressive welding and gouging environments.

Applications:

-

Air Carbon Arc Gouging: Removal of defective welds, old joints, or excess metal

-

Welding Back-Up Material: Acts as a heat-resistant backing for single-sided welding

-

Cutting & Chamfering: Useful in shipbuilding, pipeline fabrication, and heavy industry

-

Foundry Use: Suitable for repairing castings and surface defects

-

Non-Ferrous Metal Welding: Especially effective on copper, aluminum, and other soft metals

Technical Specifications (Typical):

-

Material: High-purity carbon or graphite

-

Carbon Content: ≥ 98%

-

Sizes Available:

-

Diameter: 4 mm – 16 mm

-

Length: 305 mm – 457 mm (12″ – 18″)

-

-

Coating: Copper-coated (optional) for improved conductivity and heat dissipation

-

Operating Voltage: 80 – 100 V (varies by application)

-

Polarity: Typically DCEP (Direct Current Electrode Positive)

Advantages Over Metal Electrodes:

-

Does not melt into the weld pool, making it reusable in many applications

-

Produces smoother and cleaner cuts during arc gouging

-

Lower operating cost in specific tasks like defect removal or surface prepping