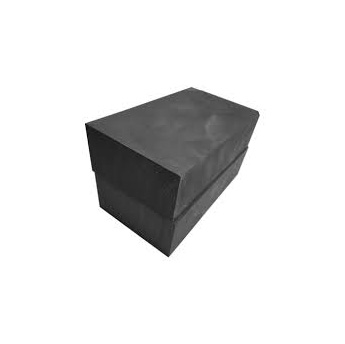

graphite welding block

A graphite welding block is a high-performance tool made from solid or composite graphite, designed to support, insulate, or fixture metal parts during welding and brazing processes. Known for its exceptional heat resistance, electrical conductivity, and chemical stability, it is widely used in both manual and automated welding setups, especially in industries that require clean, precise welds or repetitive thermal processing.

Key Features:

-

High Thermal Resistance: Withstands extreme temperatures (up to 3000°C in inert atmospheres)

-

Excellent Electrical Conductivity: Suitable for use in grounding, resistance welding, or as part of a conductive welding base

-

Non-Stick Surface: Molten metal does not adhere to graphite, allowing easy removal of workpieces and clean welds

-

Chemical Inertness: Resistant to oxidation and chemical reaction in protective atmospheres

-

Machinable: Easily shaped or grooved to hold complex or custom components in place during welding

Common Applications:

-

Welding Fixtures & Jigs: Used to hold parts in place during TIG, MIG, or resistance welding

-

Brazing and Soldering Support: Stable under repeated heating and cooling cycles

-

Heat Shields or Insulating Pads: Protects surrounding equipment or surfaces from weld heat

-

Spot Welding Electrodes (Backup Blocks): Acts as an anvil or base in automated systems

-

Glass-to-Metal Sealing: Supports delicate components during thermal bonding

Specifications (Typical):

| Property | Value Range |

|---|---|

| Material Type | High-density graphite (≥ 98% C) |

| Density | 1.7 – 1.9 g/cm³ |

| Electrical Resistivity | 8–15 µΩ·m |

| Compressive Strength | ≥ 40 MPa |

| Standard Sizes | 100×100 mm, 150×150 mm, 300×300 mm, or custom sizes |

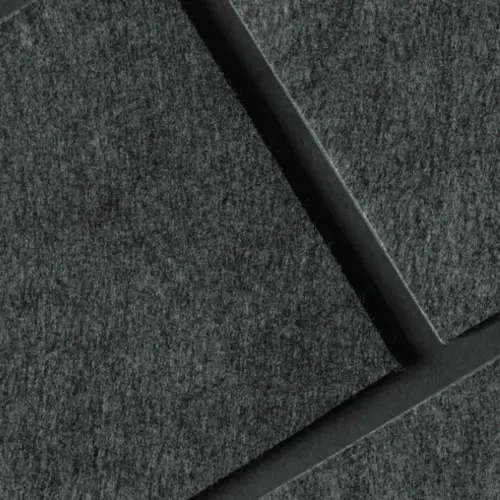

| Surface Finish | Machined, flat, or grooved (as required) |

Advantages Over Metal Fixtures:

-

Won’t warp or fuse with workpieces

-

Reusable over hundreds of weld cycles

-

Can be tailored to specific part geometries

-

Helps improve weld quality and consistency

Handling & Storage:

-

Keep in dry, low-humidity environments

-

Handle with care to avoid chipping or cracking

-

Avoid use in open flame or oxidizing conditions above 400°C unless treated or coated