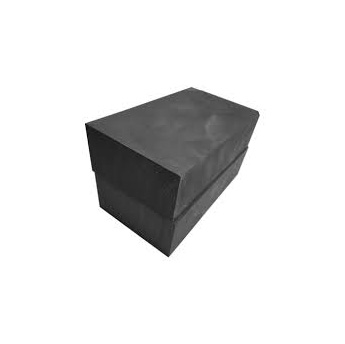

graphite used as electrode

Graphite is one of the most widely used materials for manufacturing electrodes, thanks to its unique combination of electrical conductivity, high-temperature resistance, chemical stability, and machinability. In industrial processes—especially in electric arc furnaces (EAFs)—graphite electrodes are essential for melting scrap steel and refining metals.

Graphite’s layered atomic structure allows free electrons to move easily, making it an excellent conductor of electricity, while its carbon-based composition withstands extreme heat and corrosion.

Why Graphite is Used as Electrode Material

1. High Electrical Conductivity:

Graphite conducts electricity efficiently, enabling the passage of large electrical currents in smelting and electrolysis.

2. Thermal Stability:

It can withstand temperatures up to 3500°C in non-oxidizing environments, making it ideal for use in furnaces and metallurgical reactors.

3. Chemical Resistance:

Graphite is chemically inert to most acids, alkalis, and corrosive gases, which is crucial in electrochemical applications.

4. Machinability:

Graphite can be easily machined into precise shapes like rods, plates, or custom geometries for electrodes.

Applications of Graphite Electrodes

-

Steel Manufacturing:

Used in electric arc furnaces (EAFs) and ladle furnaces (LFs) to melt scrap metal. -

Electrolysis:

Functions as anode or cathode in the production of aluminum, chlorine, sodium hydroxide, and other chemicals. -

Battery Production:

Acts as the anode material in lithium-ion and alkaline batteries. -

EDM (Electrical Discharge Machining):

Graphite electrodes are used for precise metal shaping in molds and dies. -

Glass and Ceramics Industry:

Serves as a heating element or conductor in high-temperature kilns.

Types of Graphite Electrodes

-

RP (Regular Power): For low-current density furnaces

-

HP (High Power): For higher current and temperature

-

UHP (Ultra High Power): For ultra-high temperature and continuous operation

-

Specialty Graphite: For EDM, chemical electrolysis, and laboratory electrodes

Conclusion:

Graphite is a versatile and high-performance material that remains the industry standard for electrode production. Whether for large-scale steelmaking or precision EDM applications, its unmatched combination of electrical, thermal, and structural properties makes it the preferred choice.