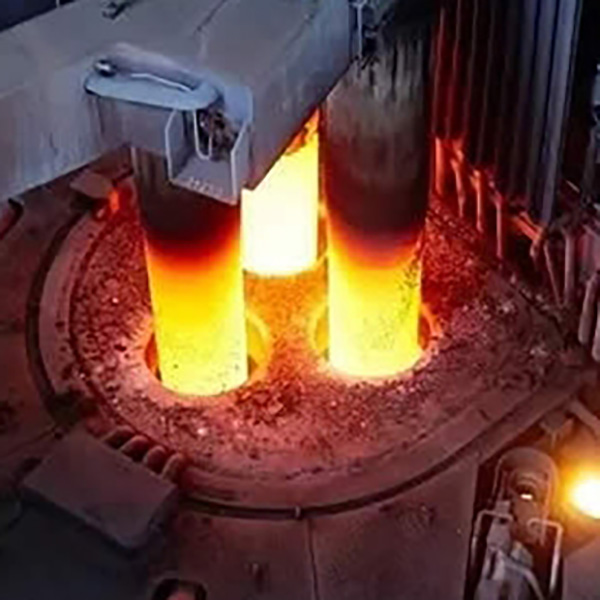

Graphite Electrodes for Steel Making

Graphite electrodes for steel making are critical consumables used in electric arc furnaces (EAFs) and ladle furnaces (LFs) during the production of steel. These electrodes serve as the primary conductors of electricity, generating the intense heat required to melt scrap steel and other raw materials. Manufactured from high-purity petroleum coke and/or needle coke, they are processed through baking, impregnation, and high-temperature graphitization to ensure excellent electrical conductivity, thermal resistance, and mechanical strength.

Available in RP (Regular Power), HP (High Power), and UHP (Ultra High Power) grades, graphite electrodes are selected based on furnace power levels, steel type, and production efficiency needs.

Key Features:

-

Superior Electrical Conductivity: Enables fast and efficient arc heating

-

Excellent Thermal Shock Resistance: Withstands high-temperature fluctuations during steelmaking

-

High Mechanical Strength: Resists breakage and oxidation in demanding furnace environments

-

Low Impurity and Ash Content: Ensures cleaner melting and higher steel quality

-

Custom Sizes Available: To match varying furnace designs and steel production requirements

Technical Grades Overview:

| Grade | Application Range | Raw Material | Resistivity (µΩ·m) | Bulk Density (g/cm³) | Max Current (A) |

|---|---|---|---|---|---|

| RP | Small/medium EAFs, non-critical steel | Petroleum coke | ≤ 10.0 | ≥ 1.53 | 10,000 – 22,000 |

| HP | Medium-power EAFs, alloy steels | Petroleum coke | ≤ 6.5 | ≥ 1.65 | 15,000 – 35,000 |

| UHP | Large-capacity EAFs, stainless steels | Needle coke | ≤ 5.5 | ≥ 1.68 | 20,000 – 50,000+ |

Note: Exact values depend on diameter and manufacturing standards.

Available Dimensions:

-

Diameter: 200 mm to 700 mm (8” to 28”)

-

Length: 1600 mm to 2700 mm

-

Threading: 3TPI or 4TPI nipple connections

-

Customization: OEM packaging, logos, and private labels available

Applications in Steel Industry:

-

Electric Arc Furnaces (EAF): Melting recycled steel scrap

-

Ladle Furnaces (LF): Secondary steel refining (temperature and composition control)

-

Submerged Arc Furnaces (SAF): For specialty alloy steel and ferroalloys

-

Specialty Steel Plants: Stainless steel, tool steel, and high-alloy steel production

Packaging & Logistics:

-

Packed in strong wooden crates

-

Protected with plastic caps and moisture-proof wrapping

-

Nipples pre-installed or packed separately based on client request

-

Export-ready documentation and tracking for international logistics

Conclusion:

Graphite electrodes are indispensable in modern steel production, offering energy efficiency, precision heating, and long service life in electric arc furnace operations. Whether you’re producing carbon steel, alloy steel, or stainless steel, choosing the right grade of graphite electrode ensures optimal furnace performance and cost-effectiveness.