Graphite Carbon Felt

Graphite carbon felt is a high-performance insulation material made from carbonized and graphitized polyacrylonitrile (PAN) or rayon fibers. Known for its lightweight, flexibility, and superior thermal stability, graphite felt is widely used in high-temperature applications such as vacuum furnaces, solar energy systems, and battery technologies like vanadium redox flow batteries.

Key Features:

-

High Temperature Resistance: Operates effectively in temperatures up to 3000°C in inert atmospheres.

-

Excellent Thermal Insulation: Low thermal conductivity minimizes heat loss in high-temperature environments.

-

Lightweight & Flexible: Easy to cut, shape, and install in various configurations.

-

Chemical Stability: Maintains structural integrity in harsh chemical environments.

-

Low Ash Content: Ensures minimal contamination, making it suitable for sensitive applications.

Common Applications:

-

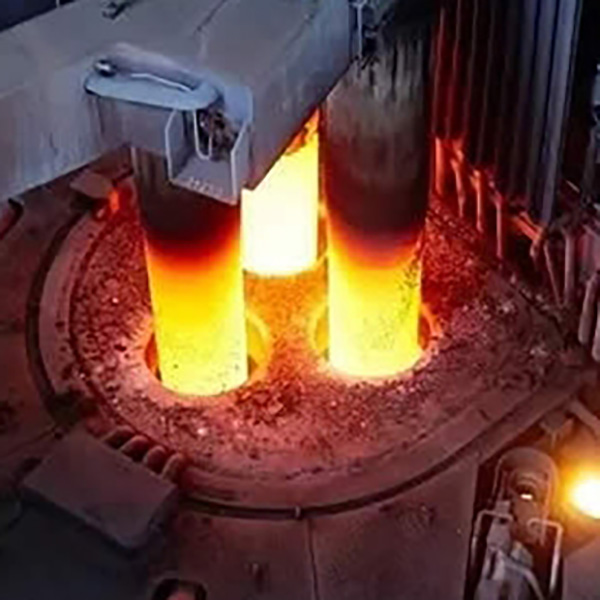

Thermal insulation in vacuum and inert gas furnaces

-

Electrode material in vanadium redox flow batteries

-

Heat shields and gasketing for high-temperature systems

-

Crystal growth furnaces for the semiconductor industry

-

Solar panel and fuel cell production

Technical Specifications:

-

Material: PAN-based or Rayon-based Graphite

-

Carbon Content: ≥ 99.5%

-

Density: 0.10–0.14 g/cm³ (customizable)

-

Thickness: 3 mm – 20 mm (custom sizes available)

-

Width: Up to 1500 mm

-

Operating Temperature: Up to 3000°C (in inert gas)

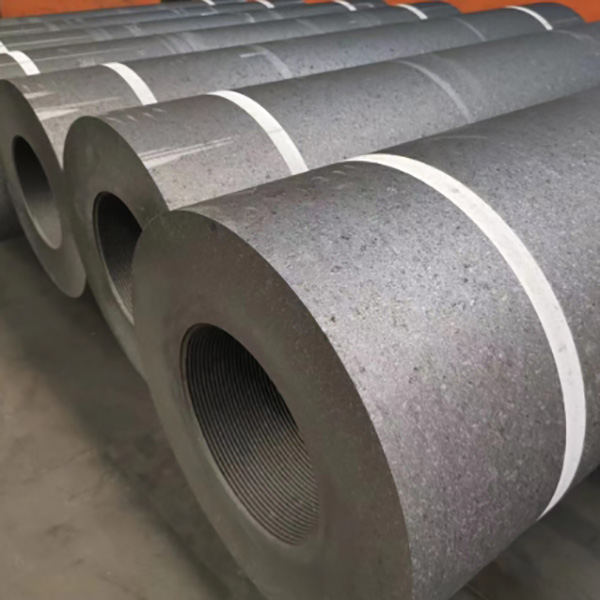

Packaging & Storage:

Graphite carbon felt is typically rolled and packaged in moisture-resistant wrapping. Store in a dry, ventilated environment to maintain product integrity.