Fangda Graphite Electrode

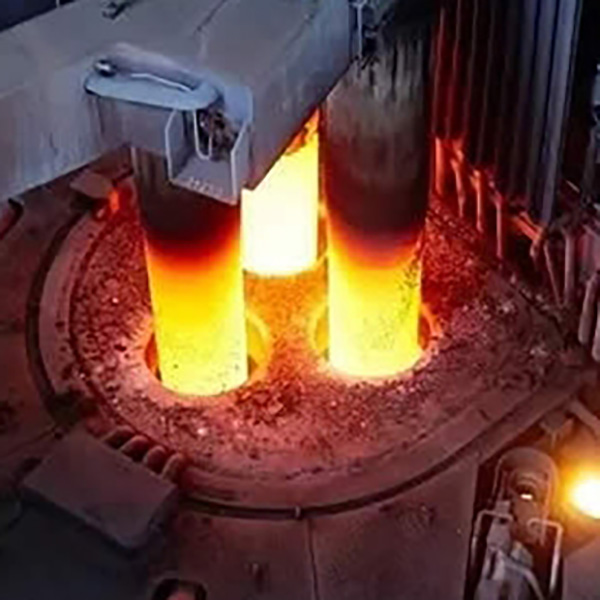

Fangda Graphite Electrodes are high-performance carbon electrodes produced by Fangda Carbon New Material Co., Ltd., one of China’s largest and most respected manufacturers of graphite materials. Designed for demanding applications such as electric arc furnace (EAF) steelmaking, ladle furnace refining, and ferroalloy production, Fangda electrodes are available in RP (Regular Power), HP (High Power), and UHP (Ultra High Power) grades.

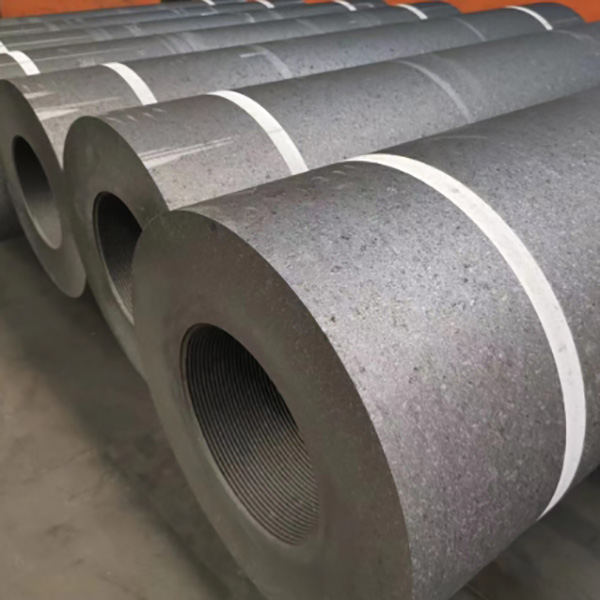

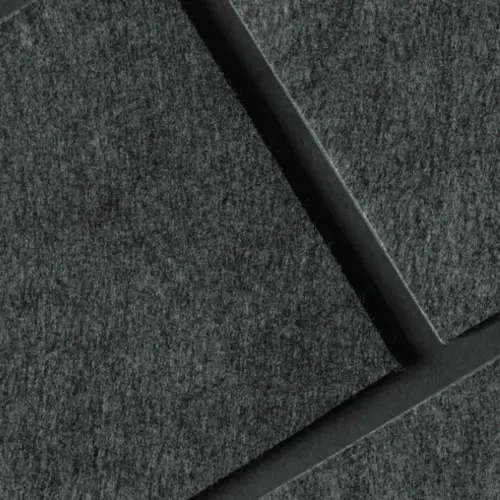

Manufactured using premium needle coke (for UHP) or petroleum coke (for RP/HP), and processed through advanced impregnation, baking, and high-temperature graphitization, Fangda electrodes deliver outstanding conductivity, thermal resistance, and structural integrity, making them a trusted choice worldwide.

Key Features:

-

Excellent Electrical Conductivity – Low resistivity for efficient energy use in EAFs

-

Superior Thermal Shock Resistance – Withstands extreme temperatures and rapid heating cycles

-

High Mechanical Strength – Reduces breakage and electrode consumption in high-load operations

-

Low Ash Content – Minimizes contamination of molten metal

-

Reliable Quality Control – Complies with GB/T, IEC, and ASTM standards; ISO 9001 certified

Available Grades:

| Grade | Suitable For | Raw Material |

|---|---|---|

| RP | Low-power EAF steelmaking | Petroleum coke |

| HP | Medium-power EAF & LF applications | Petroleum coke |

| UHP | High-power EAFs with heavy loads | Needle coke |

Typical Technical Specifications:

| Grade | Bulk Density (g/cm³) | Resistivity (µΩ·m) | Flexural Strength (MPa) | Ash Content (%) | Current Carrying Capacity (A) |

|---|---|---|---|---|---|

| RP | ≥ 1.55 | ≤ 9.5 | ≥ 8.0 | ≤ 0.5 | 10,000 – 22,000 |

| HP | ≥ 1.65 | ≤ 6.5 | ≥ 10.0 | ≤ 0.3 | 15,000 – 35,000 |

| UHP | ≥ 1.68 | ≤ 5.5 | ≥ 10.5 | ≤ 0.3 | 20,000 – 45,000+ |

Product Sizes & Packaging:

-

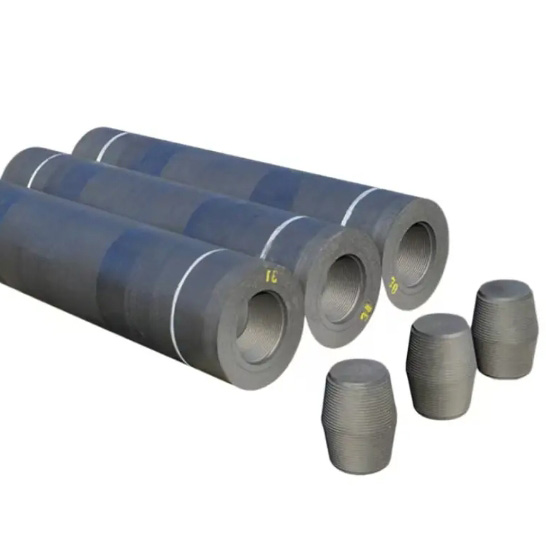

Diameters: 200 mm to 700 mm (8” to 28”)

-

Lengths: 1600 mm to 2700 mm

-

Thread Types: 3TPI, 4TPI (with matching nipples)

-

Packaging: Wooden crates with moisture-proof wrapping and protective end caps

Applications:

-

Steel production via electric arc furnaces (EAF)

-

Secondary metallurgy in ladle refining furnaces (LF)

-

Ferroalloy and silicon smelting in submerged arc furnaces (SAF)

-

Graphitization furnaces for carbon processing industries

Why Choose Fangda Graphite Electrodes?

-

Global Reputation: Exported to over 60 countries

-

Advanced Production Lines: Fully integrated carbon production from raw material to finished product

-

Strong R&D and Technical Support: Proven performance in high-consumption steel mills

-

Competitive Pricing: Cost-effective alternative to Western brands with comparable quality

Conclusion:

Fangda graphite electrodes are a trusted, high-performance solution for industrial melting and refining processes. With world-class facilities and a reputation for consistency, quality, and global support, Fangda is a leading name in the graphite electrode industry.