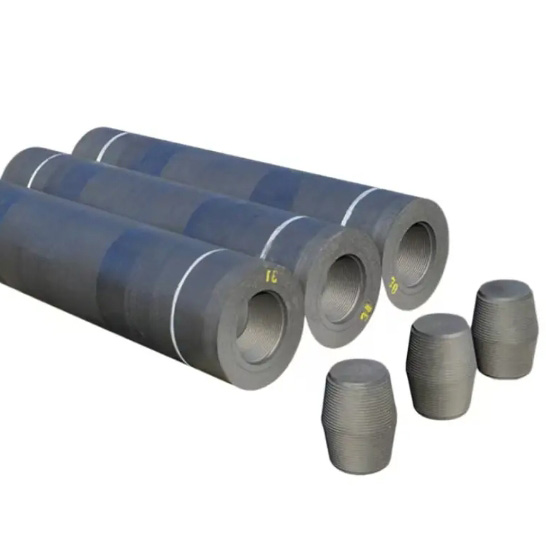

Electrode Block

Electrode blocks are large carbon or graphite components used as the conductive core material in various high-temperature, high-current industrial applications. Made from petroleum coke, pitch, or synthetic graphite, these blocks are designed to conduct electricity and resist thermal and chemical stress in electrometallurgical furnaces, electrochemical processes, and energy systems.

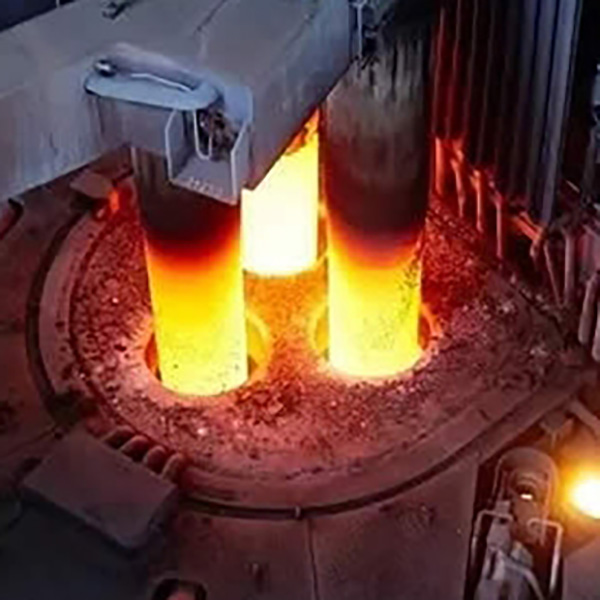

They are commonly used in the production of aluminum, ferroalloys, silicon metal, and steel, as well as in electrolysis cells and arc furnace linings.

Key Features:

-

High Electrical Conductivity: Enables efficient current transfer even under heavy industrial loads.

-

Excellent Thermal Resistance: Withstands extreme temperatures (up to 3000°C in inert atmospheres).

-

Strong Mechanical Stability: Resists cracking, thermal shock, and structural failure.

-

Low Ash Content: Reduces contamination and maximizes process purity.

-

Customizable Shapes and Sizes: Can be cut, machined, or molded to fit specific furnace or reactor designs.

Common Applications:

-

Submerged Arc Furnaces (SAF): For silicon, ferrochrome, and manganese alloy production

-

Electrolytic Cells: In aluminum smelting and chemical processing

-

Graphite Furnace Linings and Electrodes: As part of steelmaking or high-temperature sintering systems

-

Cathode or Anode Blocks: In aluminum reduction pots (Hall-Héroult process)

-

Carbon Brushes and Conductive Components: In heavy electrical systems or rail transport

Technical Specifications (Typical):

| Property | Value Range |

|---|---|

| Material Type | Carbon / Graphite |

| Bulk Density | 1.55 – 1.85 g/cm³ |

| Electrical Resistivity | 8 – 15 µΩ·m |

| Flexural Strength | 10 – 25 MPa |

| Ash Content | ≤ 0.3% |

| Operating Temp. | Up to 3000°C (inert) |

| Dimensions | Custom or standard |

Available Grades:

-

Carbon Electrode Block – More cost-effective, used in aluminum and silicon industries

-

Graphite Electrode Block – Higher performance for steel, glass, and high-tech industries