EAF Electrode Price

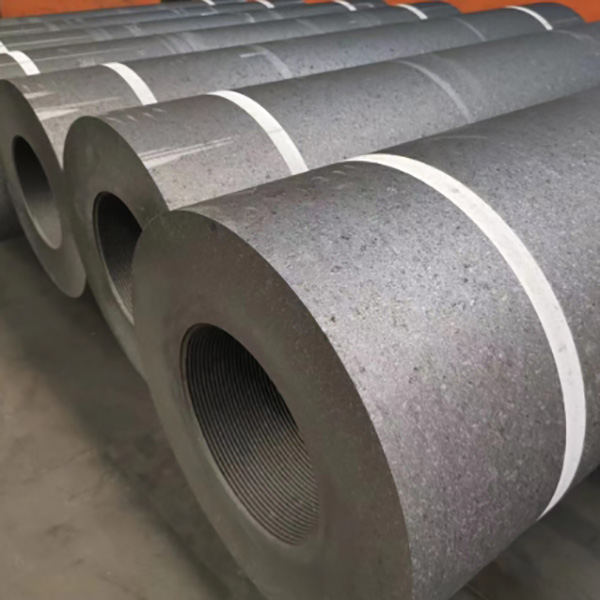

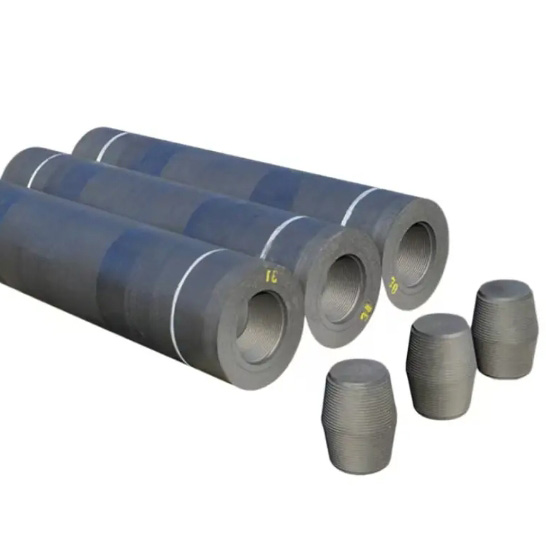

Electric Arc Furnace (EAF) electrodes, typically made of graphite, are essential consumables used in steel production by melting scrap or raw materials. The price of EAF electrodes depends on several factors, including grade (RP, HP, UHP), diameter, raw material type, market conditions, and regional supply-demand trends.

Typical Price Range (as of mid-2025)

| Electrode Grade | Diameter (mm) | Price (USD/ton) | Notes |

|---|---|---|---|

| RP (Regular Power) | 250–400 mm | $1,800 – $2,300 | Lower conductivity, used in small/medium furnaces |

| HP (High Power) | 350–500 mm | $2,400 – $2,900 | Medium-load steel production |

| UHP (Ultra High Power) | 400–700 mm | $3,000 – $4,500+ | High-end furnaces, large current capacity |

| EAF Nipples (matching) | — | $300 – $700 per ton | Often sold separately |

Prices fluctuate based on needle coke availability, energy costs, anti-dumping tariffs, and global steel production trends.

Cost Drivers:

-

Raw Material Price: Needle coke (for UHP) is more expensive than petroleum coke (for RP/HP)

-

Furnace Size & Load: Larger diameters and higher current capacity increase costs

-

Global Demand: Prices rise with steel production or supply chain disruptions

-

Supplier Region: Chinese, Indian, European, and US suppliers may offer different rates based on local policies and logistics

Major Suppliers & Exporters:

-

Fangda Carbon (China)

-

Tokai Carbon (Japan)

-

Showa Denko (Resonac) (Japan)

-

Graphite India (India)

-

GrafTech International (USA)

Packaging:

-

Wooden crates with steel strapping

-

Moisture-resistant covers

-

Nipple ends protected with plastic caps

-

Custom export packaging available

Conclusion:

The EAF electrode price varies significantly with grade, size, and market dynamics. Buyers should evaluate technical requirements, furnace design, and long-term procurement strategies to manage electrode costs effectively.