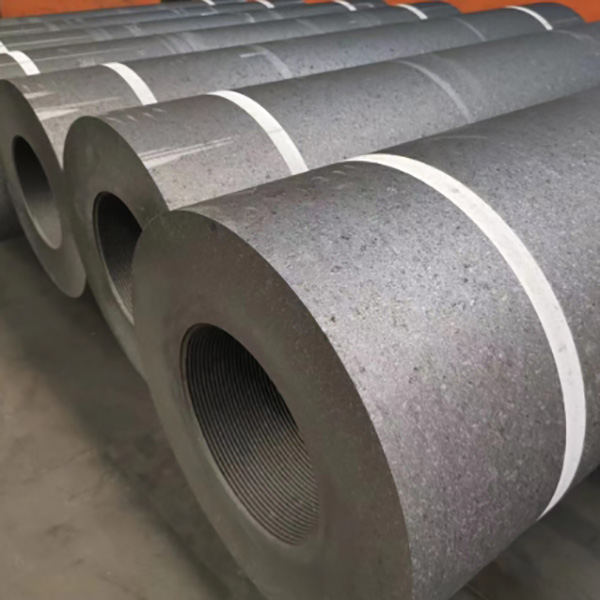

AGX Graphite Electrodes

AGX Graphite Electrodes are high-performance carbon electrodes manufactured by AGX Group—a globally recognized supplier of premium-grade graphite materials. Designed for use in electric arc furnaces (EAFs), ladle furnaces (LFs), and submerged arc furnaces (SAFs), these electrodes offer excellent electrical conductivity, thermal resistance, and mechanical strength.

Produced using high-purity needle coke or petroleum coke, and processed through high-temperature graphitization, AGX electrodes meet or exceed international standards such as IEC 60239 and YB/T 4088. They are available in Regular Power (RP), High Power (HP), and Ultra High Power (UHP) grades.

Key Features:

-

High Electrical Conductivity: Ensures stable arc performance with reduced energy loss

-

Outstanding Thermal Resistance: Withstands high furnace temperatures and thermal shock

-

Superior Mechanical Strength: Reduces breakage and improves durability during furnace operations

-

Low Impurity Content: Minimizes contamination of molten steel or alloys

-

Multiple Grades Available: Tailored to different furnace capacities and melting requirements

Available Grades:

-

RP (Regular Power): For low-power EAF operations

-

HP (High Power): For medium-power steelmaking processes

-

UHP (Ultra High Power): For high-efficiency EAFs requiring large current loads

Technical Specifications (Typical):

| Grade | Bulk Density (g/cm³) | Electrical Resistivity (µΩ·m) | Flexural Strength (MPa) | Ash Content (%) | Current Capacity (A) |

|---|---|---|---|---|---|

| RP | ≥1.55 | ≤9.5 | ≥8.0 | ≤0.5 | 10,000–22,000 |

| HP | ≥1.65 | ≤6.5 | ≥10.0 | ≤0.3 | 15,000–35,000 |

| UHP | ≥1.68 | ≤5.5 | ≥10.5 | ≤0.3 | 20,000–45,000 |

Note: Specifications vary by diameter and manufacturing batch.

Available Sizes:

-

Diameter: 200 mm to 700 mm (8″ to 28″)

-

Length: 1600 mm to 2700 mm

-

Nipple Threads: 3TPI, 4TPI, or custom thread interfaces

Applications:

-

Steel recycling in electric arc furnaces (EAFs)

-

Secondary steel refining in ladle furnaces (LFs)

-

Ferroalloy and silicon metal production in submerged arc furnaces (SAFs)

-

Non-ferrous metallurgy and graphitization furnaces

Packaging & Delivery:

-

Packed in wooden crates with steel straps

-

Nipple ends protected by plastic caps

-

Moisture-proof wrapping and impact-resistant padding

-

Custom labeling and barcoding available upon request

Conclusion:

AGX graphite electrodes are engineered for consistent performance, long life, and high efficiency across a wide range of furnace operations. Backed by strict quality control and global service, AGX is a trusted brand in the steelmaking and metallurgical industries.